A method for controlling the melting superheat degree of pouring tial alloy in a water-cooled crucible

A water-cooled crucible and superheating technology, which is applied in metal processing equipment, casting melt containers, manufacturing tools, etc., to improve casting yield, reduce shrinkage cavity and shrinkage defects, and ensure accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

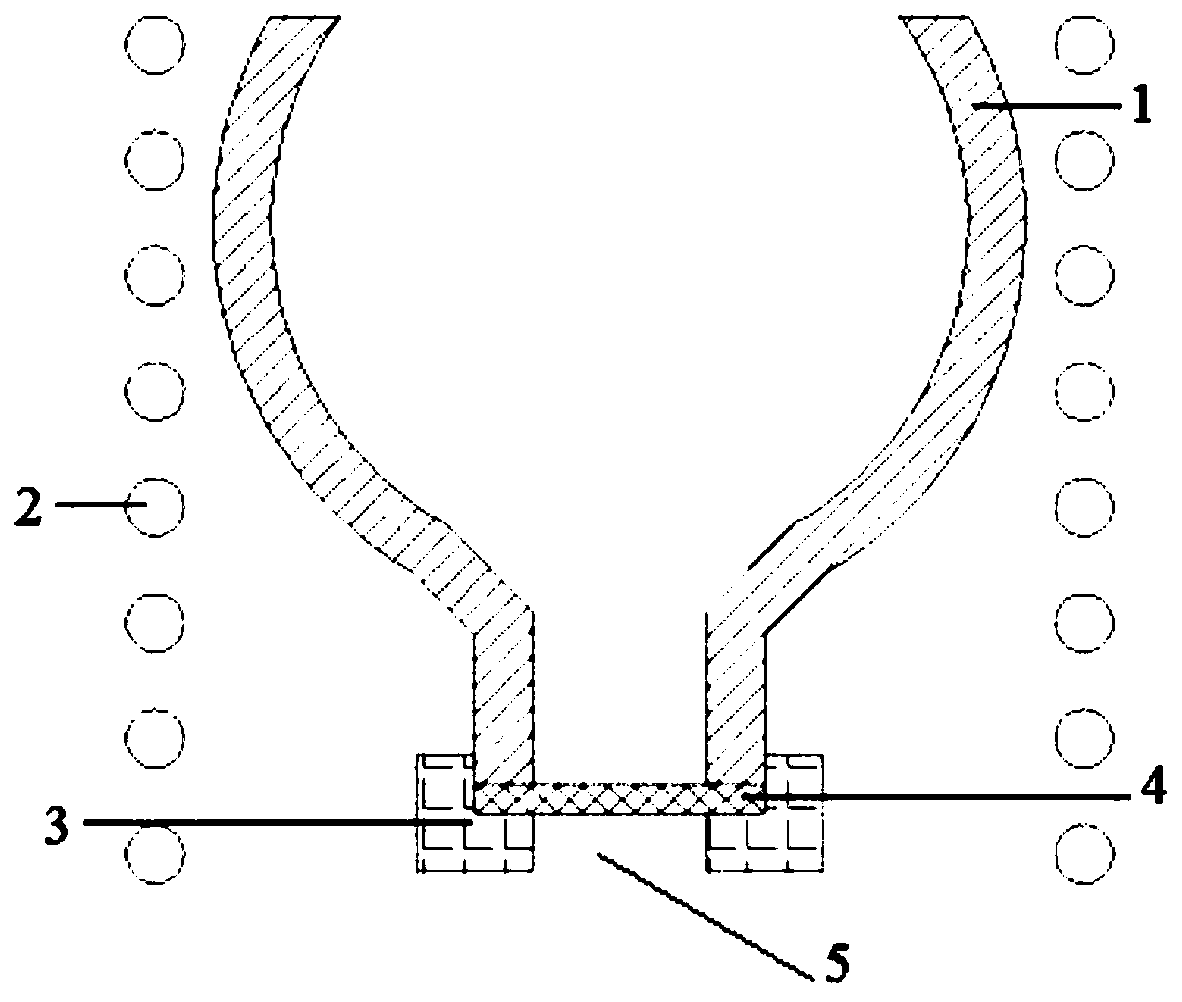

[0042] Taking a turbine with a diameter of 160 mm poured from a TiAl melt in a water-cooled crucible as an example, the characteristic parameters of the tundish used in the present invention are:

[0043] (1) The weight of the master alloy in the water-cooled crucible is 5kg, the capacity of the main body 1 of the tundish is 6kg, the maximum outer diameter is 170mm, the height is 200mm, the diameter of the material storage area is 150mm, the diameter of the feed port is 80mm, and the section slope of the confluence area is 45°. The diameter of the liquid outlet 5 is 40mm, and the length of the liquid outlet 5 is 30mm;

[0044] (2) The main body 1 of the tundish is made of ceramics with yttrium oxide as the surface layer and alumina as the back layer support. The purity of yttrium oxide is 99.92%, the bending strength of the ceramic is 5MPa, and the heat storage coefficient is 6800J·s -0.5 m -2 ·K -1 , the thermal conductivity is 7.2W·m -1 ·K -1 ;

[0045] (3) The thicknes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com