High-power professional audio power amplifier based on Peltier effect radiation technology

A Peltier effect, audio power technology, applied in power amplifiers and other directions, can solve problems such as the pipe-fin heat dissipation structure is not suitable for audio power amplifiers, high manufacturing costs, and increased difficulty in the micro-channel heat dissipation process, to improve cooling. Efficiency, unlocking cooling bottlenecks, and the effect of reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

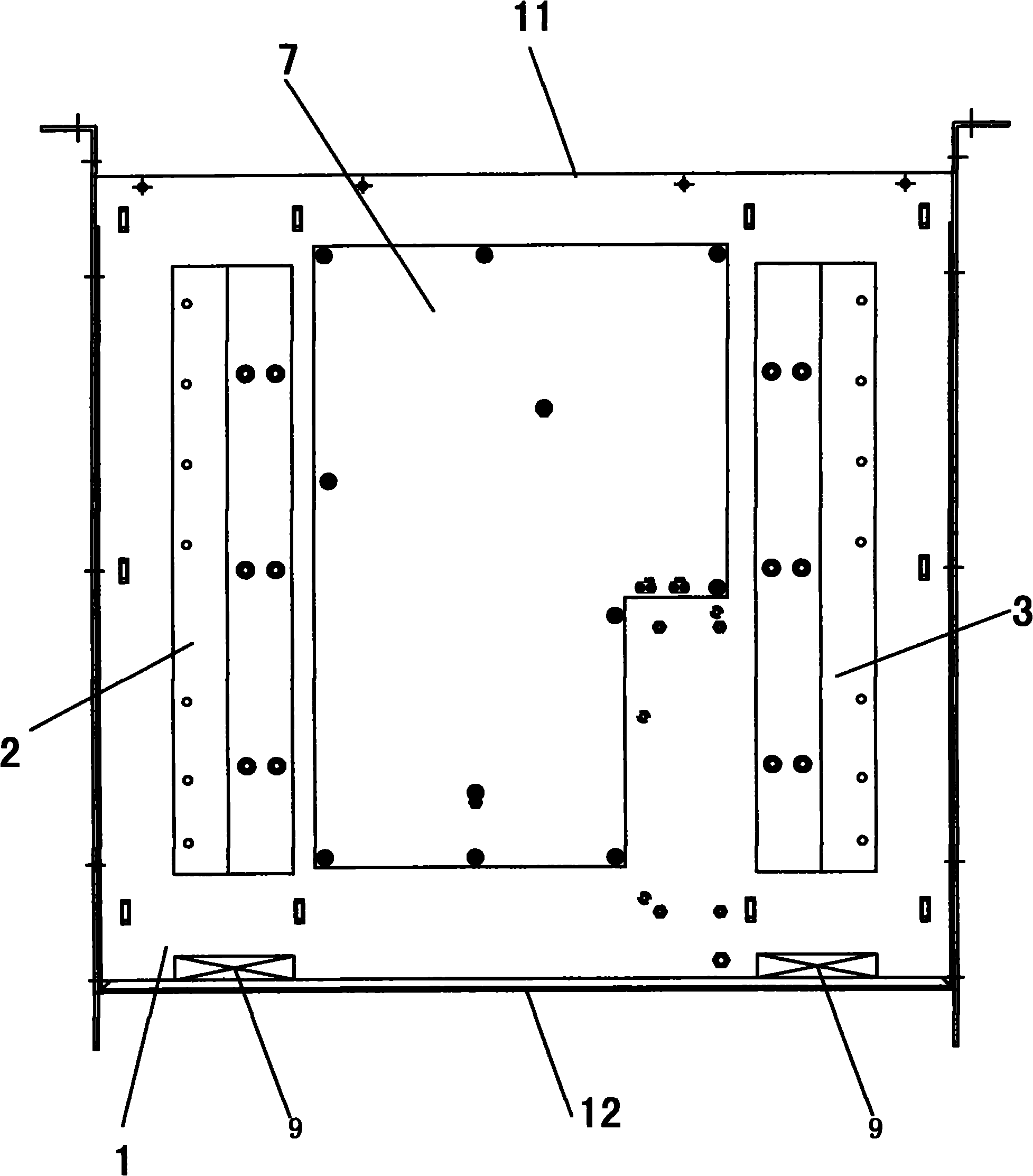

Embodiment 1

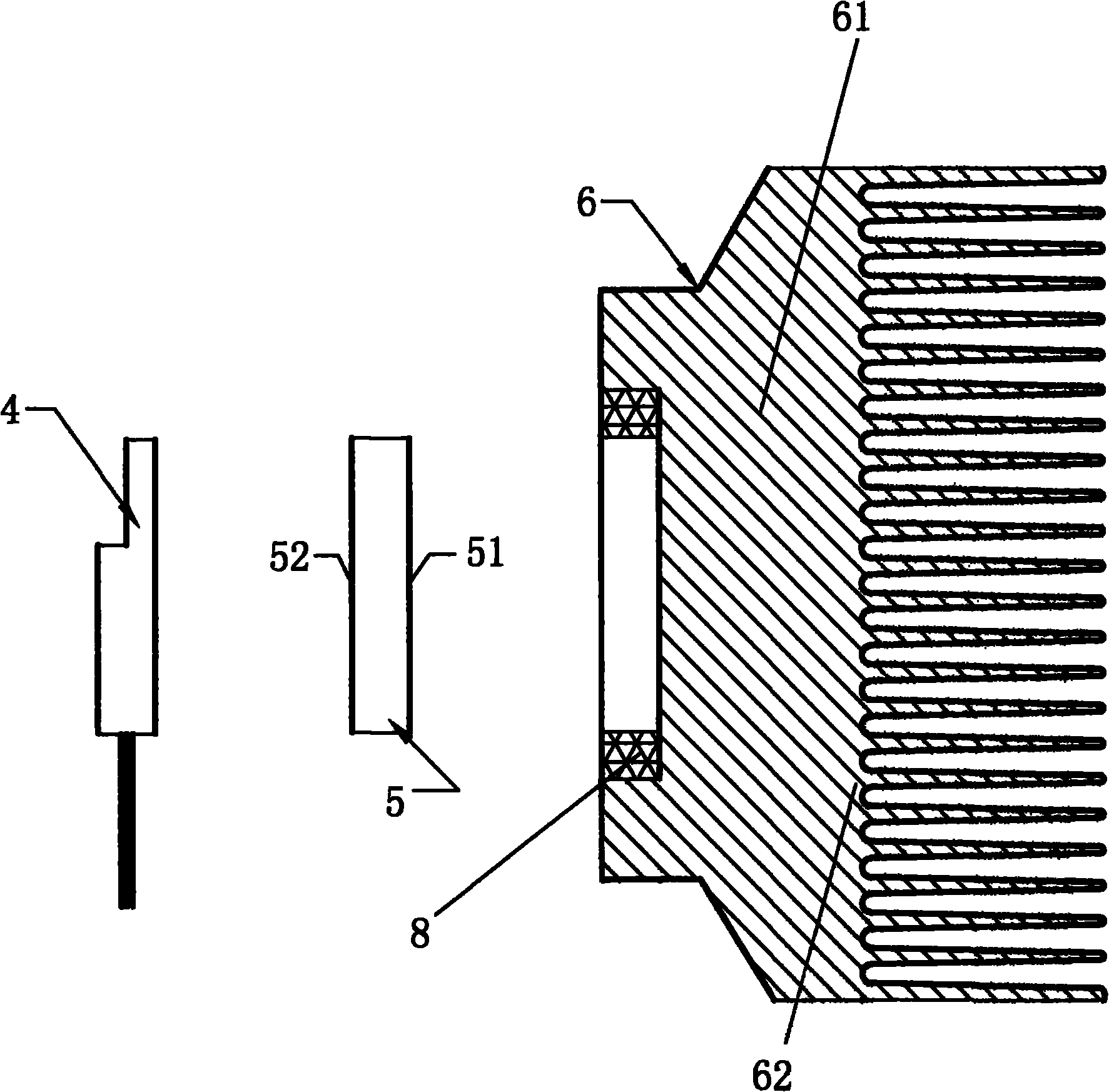

[0019] Example 1, see image 3 , the bottom of the base of the radiator 1 is provided with a groove, the semiconductor cooling chip 5 is sheet-shaped, and placed in the groove, and placed in the gap between the groove wall and the semiconductor cooling chip 5 The silica gel 8 that acts as heat insulation, the back of the power amplifier chip 4 is coated with thermally conductive silicone grease and then pasted on the cold end surface of the semiconductor refrigeration chip 5 .

Embodiment 2

[0020] Example 2, see Figure 4 , is the further optimization of embodiment 1, and the purpose is to further improve the heat dissipation effect. On the basis of embodiment 1, an inner cooling fan 20 is also respectively arranged at the ends of the multi-piece cooling fins 62 of the two radiators 6 , the inner cooling fan 20 is located between the radiator 6 and the outer cooling fan 10 . The specific fixing method is: a fixed plate 63 is fixed on the outer wall of the radiator 6, and the fixed plate 63 surrounds a plurality of cooling fins, and the two side plates of the fixed plate 63 are respectively fixed on the outer wall of the radiator 6 by screws. And the panel between the two side plates of the fixed plate 63 is provided with a mounting hole, and the inner cooling fan 20 is housed in the hole, and the inner cooling fan 20 is perpendicular to the cooling fins, and can be placed in the gap between the cooling fins. Blow the air to dissipate the heat on the heat sink in...

Embodiment 3

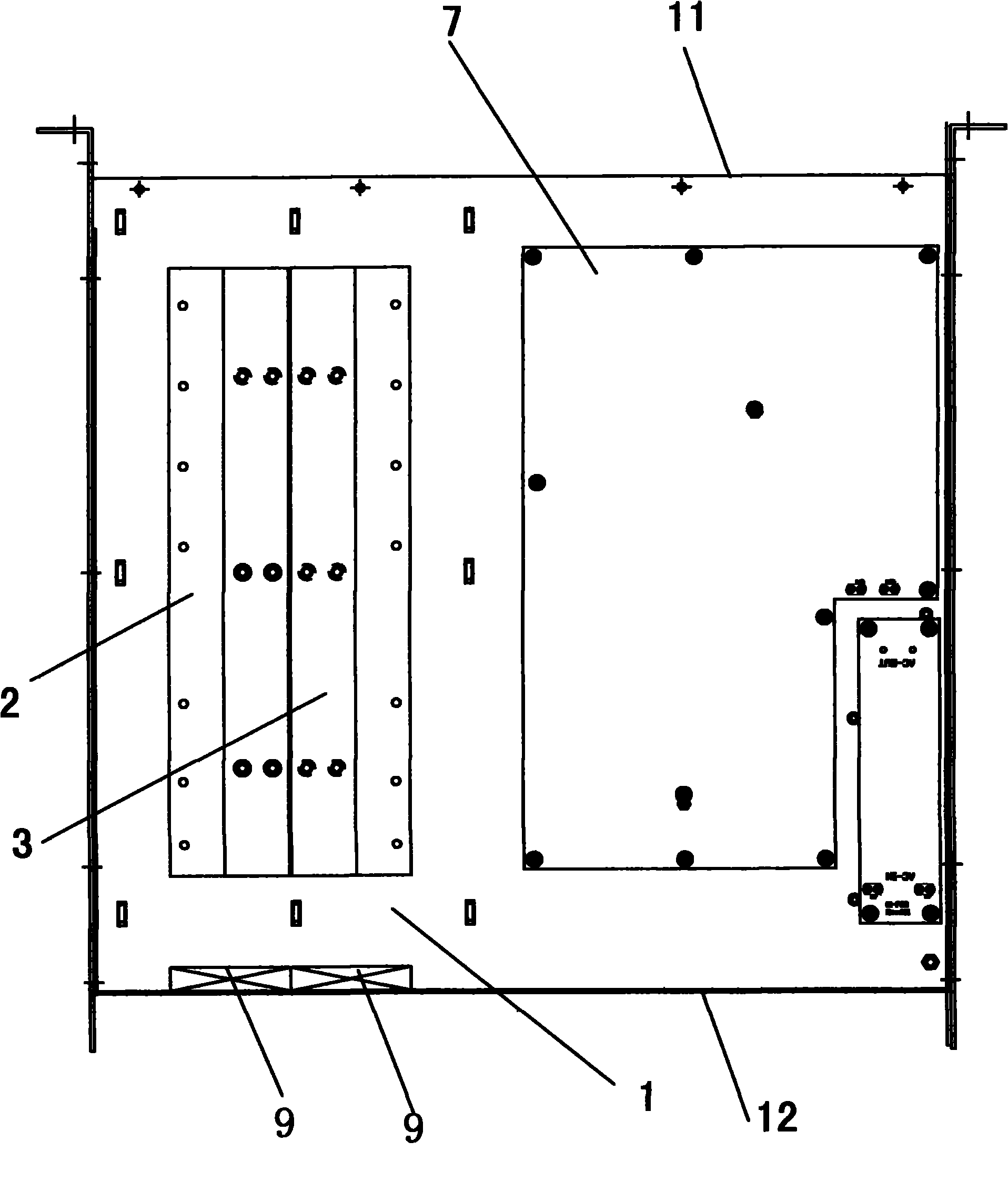

[0021] Example 3, see Figure 5 On the side wall of the base of the heat sink 1, a sheet-shaped semiconductor cooling chip 5 is fixed, and the cold end surface of the semiconductor cooling chip 5 is bonded to the power amplifier chip; the back of the power amplifier chip 4 is coated with thermally conductive silicone grease Finally, it is fixed on the hot end surface of the semiconducting cooling sheet 5. Two sets of power amplification chips 4 and semiconductor cooling chips 5 are fixed on the side wall of the base of the radiator 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com