Envelope for luminous elements of semiconductor in large power

A technology of light-emitting components and semiconductors, applied in semiconductor devices, semiconductor/solid-state device parts, electrical components, etc., can solve the problem of small contact area between LED light-emitting chip and heat dissipation carrier, no complete improvement of heat dissipation efficiency, and large heat pipe volume. and other problems, to achieve the effect of improving refrigeration efficiency, small size and saving volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

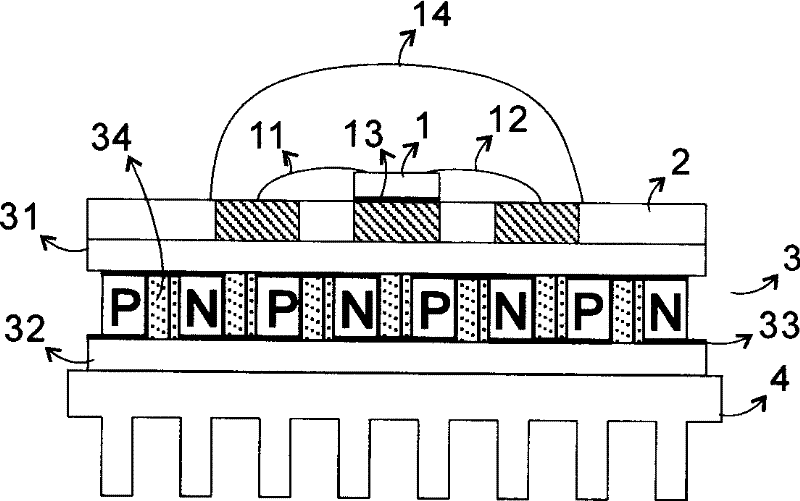

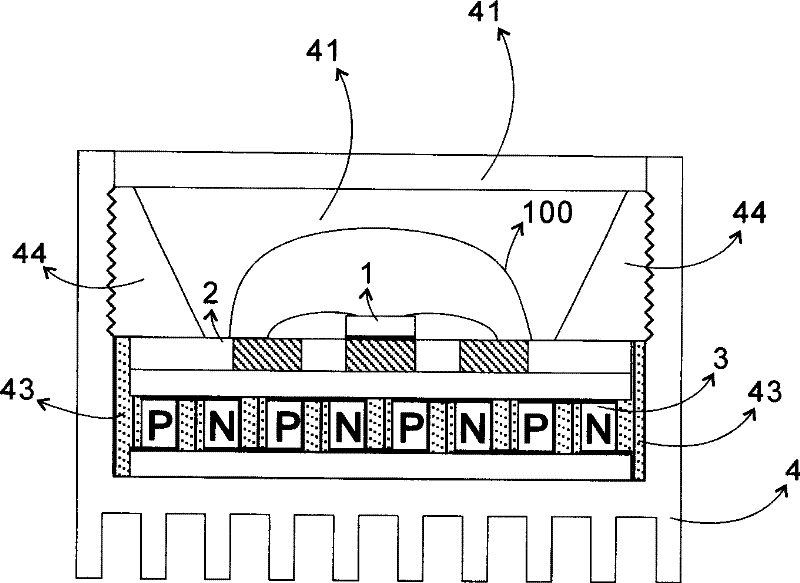

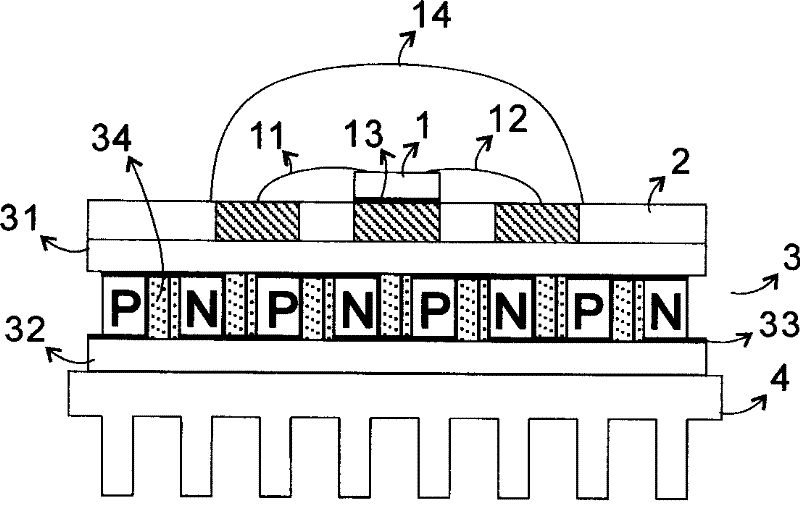

[0022] Hereinafter, preferred embodiments of the present invention will be described with reference to the accompanying drawings. With reference to the drawings, wherever possible, the same reference numbers will be used throughout the drawings to refer to the same or like parts. Also, it is considered that detailed descriptions of known functions and structures of key points of the present invention will be omitted.

[0023] figure 1 It is a cross-sectional view of the high-power semiconductor light-emitting element package of the present invention. The high-power semiconductor light-emitting element package includes at least one LED chip 1 electrically connected inside and outside; an LED substrate 2, and each of the at least one or more LED chips 1 is fixed on the front side of the substrate 2. , LED chip 1 is packaged with silicon material or epoxy resin. Wherein, each LED chip 1 provided with internal and external electrical connections is bonded to an external circuit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com