Accurate cutting temperature measuring device for turn-milling machining

A cutting temperature and accurate technology, applied in measuring devices, components using electrical devices, thermometers, etc., can solve the problems of discontinuous signal acquisition, inconvenient installation of thermocouples, and unsuitable coating tools.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below.

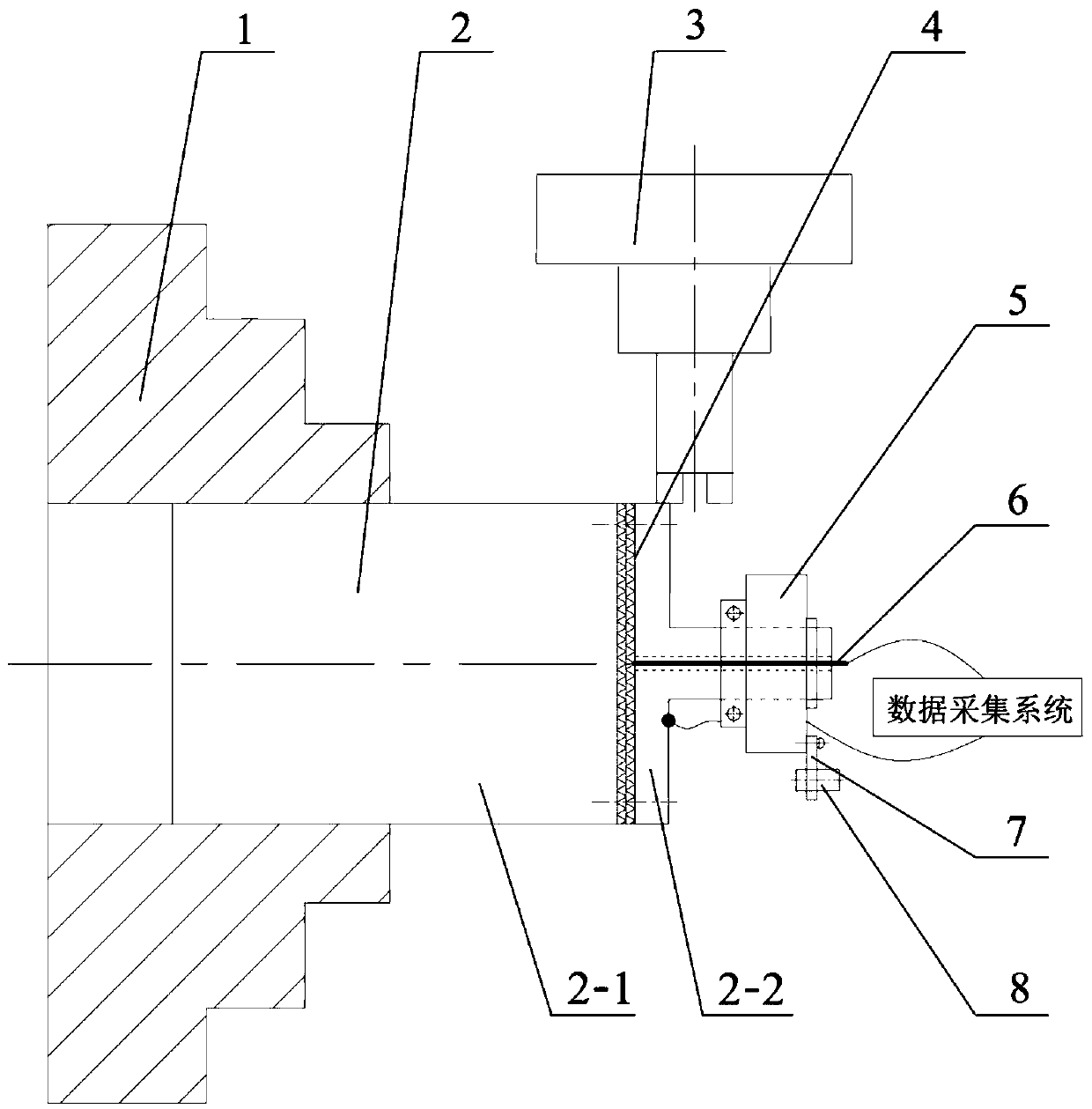

[0020] like Figure 1 to Figure 5 As shown, the present invention includes a workpiece temperature measurement sample 2, a conductive slip ring 5, a plurality of thermocouple wires 6, a cylindrical insulating tube 11, a fixed bracket and a data acquisition system,

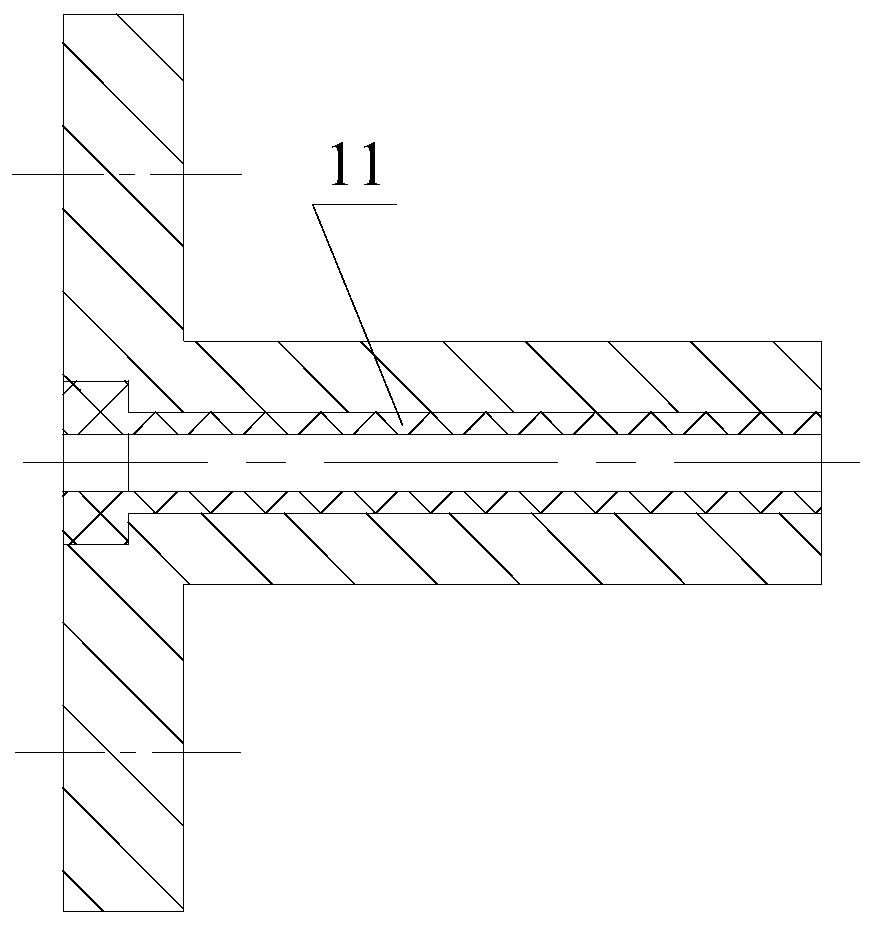

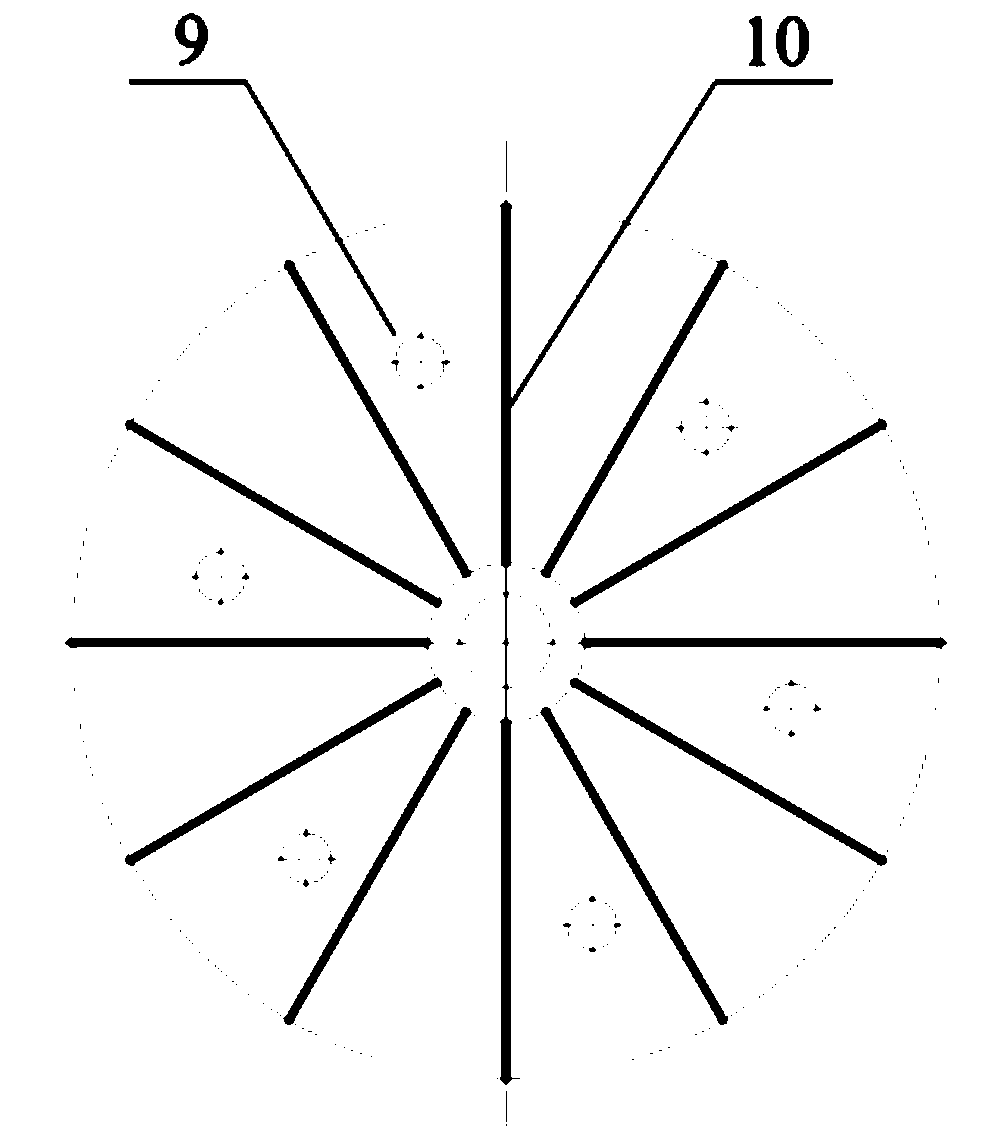

[0021] The workpiece temperature measurement sample 2 is composed of part I2-1 and part II2-2, the materials of part I2-1 and part II2-2 are the same, the shape of part I2-1 is cylindrical, and the shape of part II2-2 is A hollow shaft with a disk 9 at one end, the diameter of the disk 9 of the part II2-2 is the same as that of the part I2-1, and a plurality of grooves 10 are opened on one end of the disk 9 of the part II2-2, each groove 10 The two ends are respectively connected with one end of the hollow shaft in the center of the disc 9 and the outer edge of the disc 9, and the cylindrical insulating tube 11 is inserted into and fixed in the hollow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com