Method for continuously and rollingly paving asphalt on dynamic flat ground of skid pad

A proving ground and dynamic technology, which is applied in the field of multi-machine joint paving in asphalt pavement construction, can solve the problems of increased paving machinery costs, and achieve the effect of reducing investment and construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

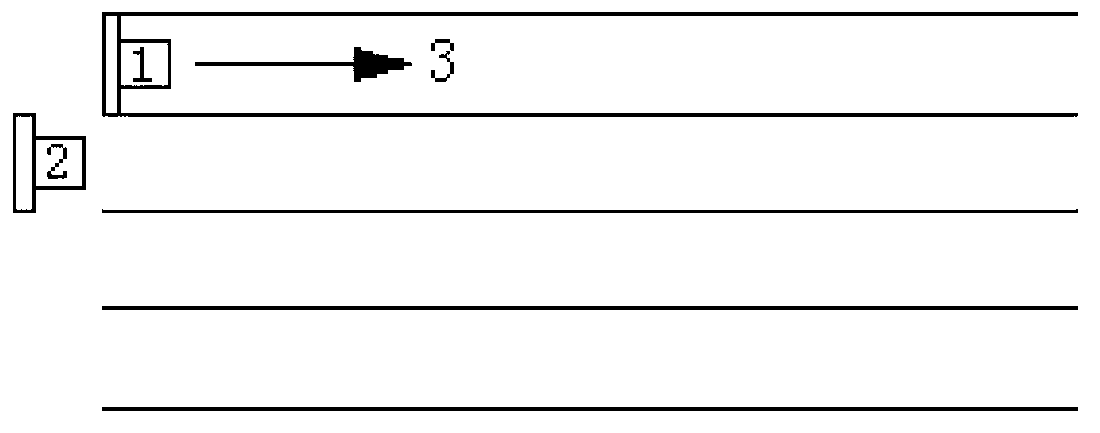

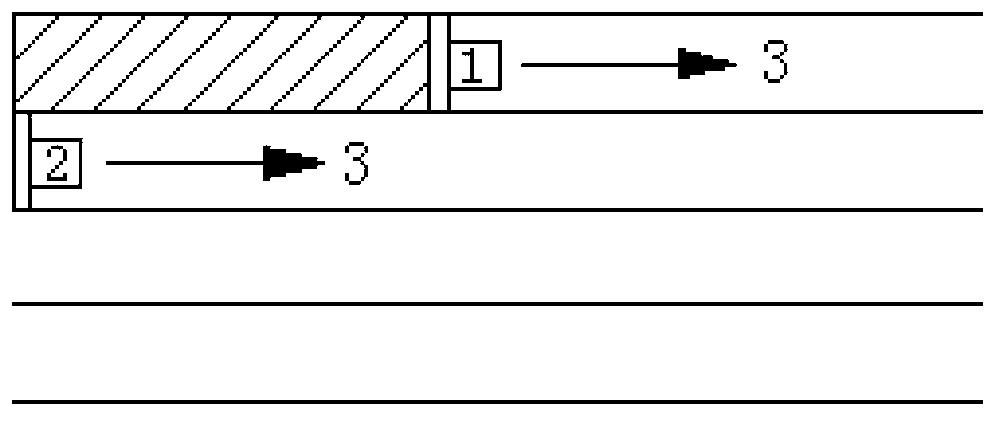

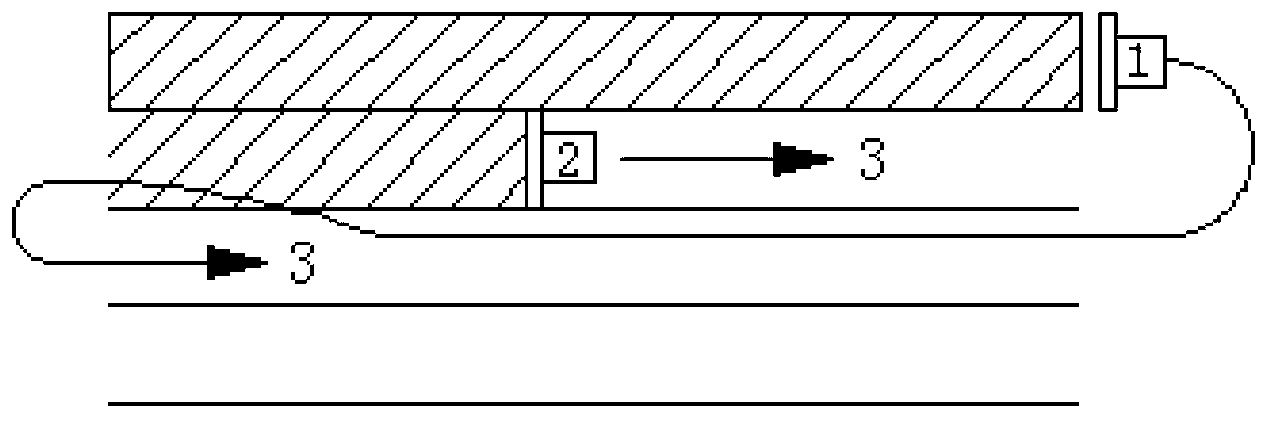

[0020] The method for continuously rolling asphalt paving on a test track, including the following implementation steps:

[0021] a. Selection of the number of paver machines and determination of the distance between the front and rear machine positions: at least two or more paver machines are required to achieve continuous rolling paving, and the distance between the front and rear paver machine positions shall not exceed 100m, and then according to the length of each paving area Determine the number of paver according to the paving speed;

[0022] b. Treatment on the side of the pavement at the back of the pavement: before paving, first bake and heat the lower bearing layer with a blowtorch to prevent the colder lower bearing layer from absorbing the heat of the asphalt. The baking length should be longer than that of the paver The first 10~15m, the width is about 1m, across the joint position, reserve about 40cm not to be rolled when the first pavement is rolled, as the ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com