Unequal-thickness deep-cavity shell mold aluminum alloy component squeeze casting device and using method thereof

A technology for aluminum alloy components and extrusion casting, which is applied in the field of extrusion casting devices for aluminum alloy components, can solve the problems of shrinkage porosity and thermal cracking, shrinkage holes at hot joints, and non-dense formed parts, and achieves the effect of high utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

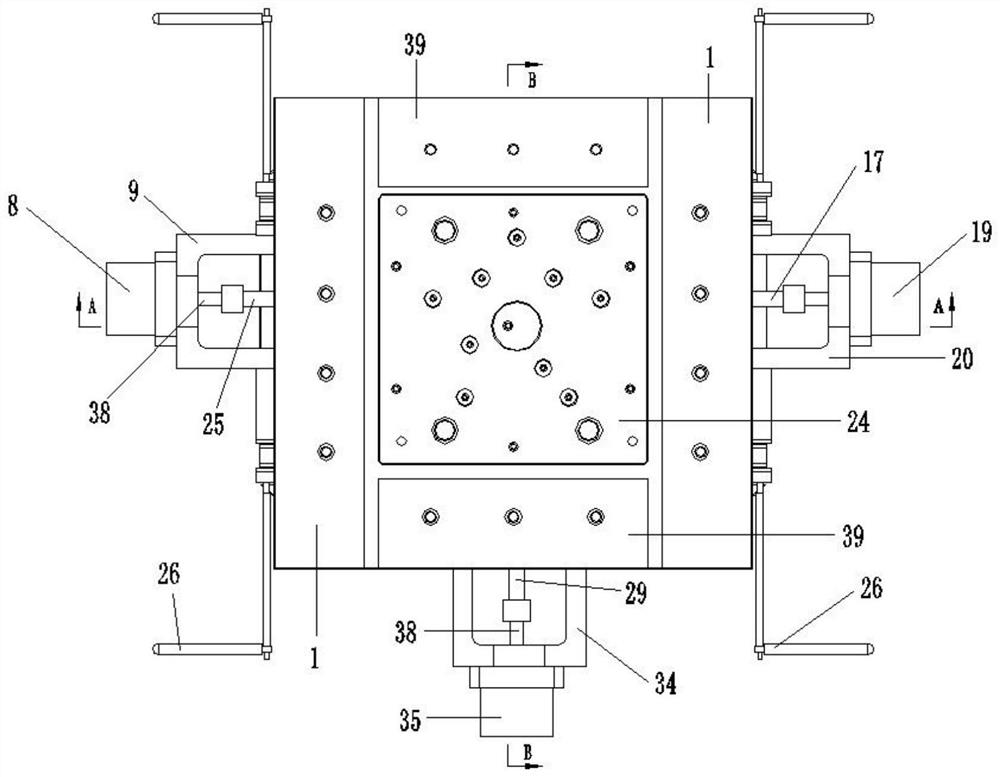

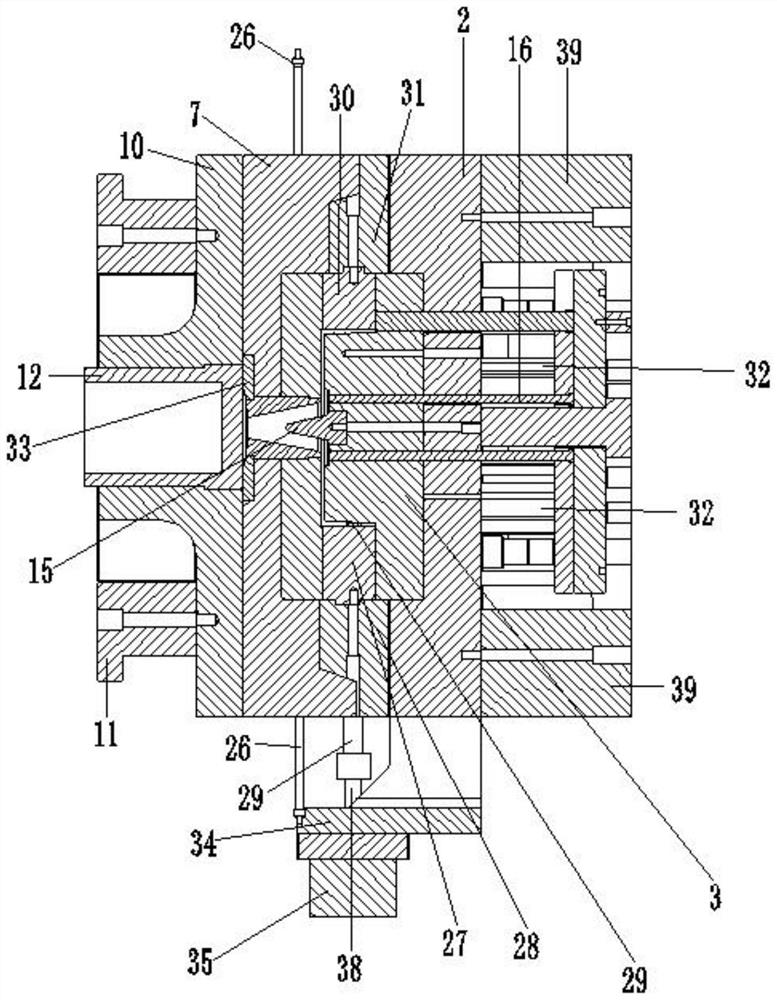

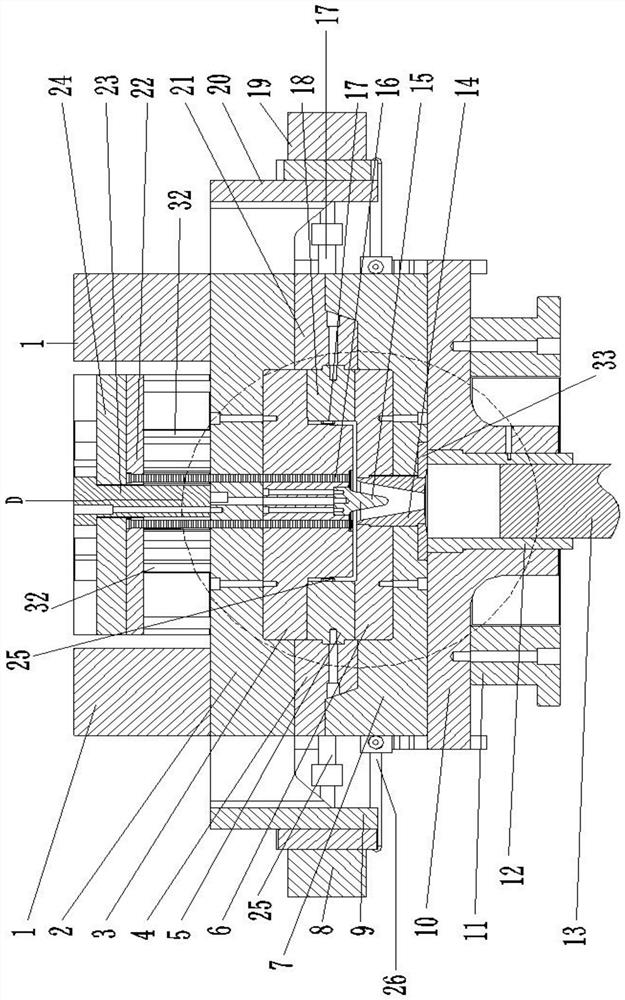

[0049]DETAILED DESCRIPTION OF THE INVENTION The present embodiment is an inequal thick deep cavity aluminum alloy member extruded casting device, such asFigure 1 - Figure 13As shown, it is specifically formed by a side core assembly, a mold type cavity assembly, a mold fixing mounting assembly, an open-pending mechanism assembly, a member assembly, and a component casting mechanism assembly;

[0050]The side core assembly is a left-liquid pressure cylinder fixing block 9, a left hydraulic cylinder 8, a left-filled rod 25, a right hydraulic cylinder fixed block 20, a right hydraulic cylinder 19, a right replenishing rod 17, a front hydraulic cylinder fixed block 34, the front hydraulic cylinder 35 and the front replenup rod 29 are composed; the left hydraulic cylinder fixing block 9 is mounted on the left end of the upper mold fixing sleeve 2, and the left hydraulic pressure; the left hydraulic pressure The cylinder 8 is mounted on the outer side wall of the left hydrating cylinder fixi...

specific Embodiment approach 2

[0056]DETAILED DESCRIPTION OF THE INVENTION The present embodiment is different from that of the particular embodiment: the pull-up slope of the upper mold 3 is 1.5 °. Others are the same as those of the specific embodiments.

specific Embodiment approach 3

[0057]DETAILED DESCRIPTION OF THE INVENTION 3: The present embodiment and the specific embodiment one or two different: the lower mold fixing sleeve 7 and the left side mold fixing sleeve 4, the right side mold fixing sleeve 21, the front side mold fixing sleeve 28 and the rear The angle of the inclined surface and the horizontal plane in the surface of the side mold fixing sleeve 31 is 120 °. Others are the same as those of the specific embodiments.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slope | aaaaa | aaaaa |

| Slope | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com