Novel hub die structure

A wheel hub mold, a new technology, applied in the direction of casting mold, core, casting mold composition, etc., can solve the problems of few defects, achieve the effect of reducing the volume of hot nodes, reducing the total weight, and shortening the cooling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

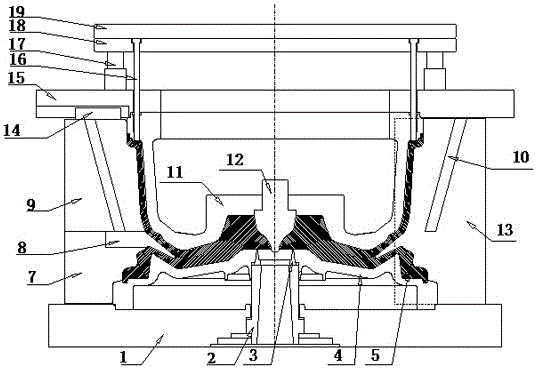

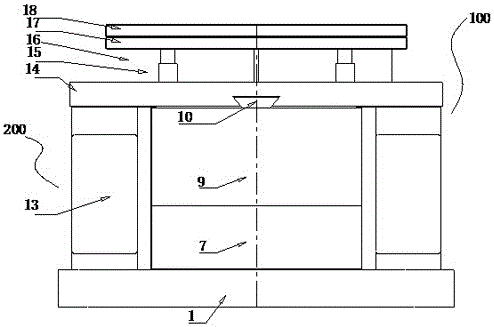

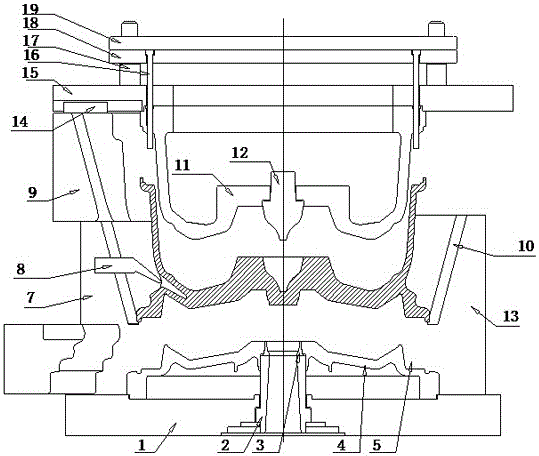

[0020] refer to Figure 1 to Figure 3 , a new wheel hub mold structure, including a bottom plate 1, a liquid suction pipe 2, a sprue sleeve 3, a bottom mold assembly 4 on the bottom plate 1, an upper mold assembly 100, a side mold assembly 200, and a side mold assembly 200 includes an upper side mold 9 and a lower side mold 7 that are movably connected.

[0021] After the upper mold assembly 100, the bottom mold assembly 4, and the side mold assembly 200 are molded together, a mold cavity is formed, and the casting 5 is located in the mold cavity.

[0022] An insert 8 is arranged between the parting surfaces of the upper mold 9 and the lower mold 7 .

[0023] Upper mold assembly 100 includes upper mold slide bar 10, upper mold 11, splitter cone 12, triangular block 13; dovetail guide slider 14; upper mold plate 15, ejector pin 16 guide column 17; ejector pin plate 18, ejector pin platen 19 .

[0024] One end of the insert 8 is inserted into the parting surface of the side m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com