Hub mold rim water cooling device

A wheel hub mold and cooling device technology, applied in the field of mechanical casting, can solve the problems of long casting cycle, prolong casting cycle, low production efficiency, etc., and achieve the effects of reducing scrap rate, shortening casting cycle, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

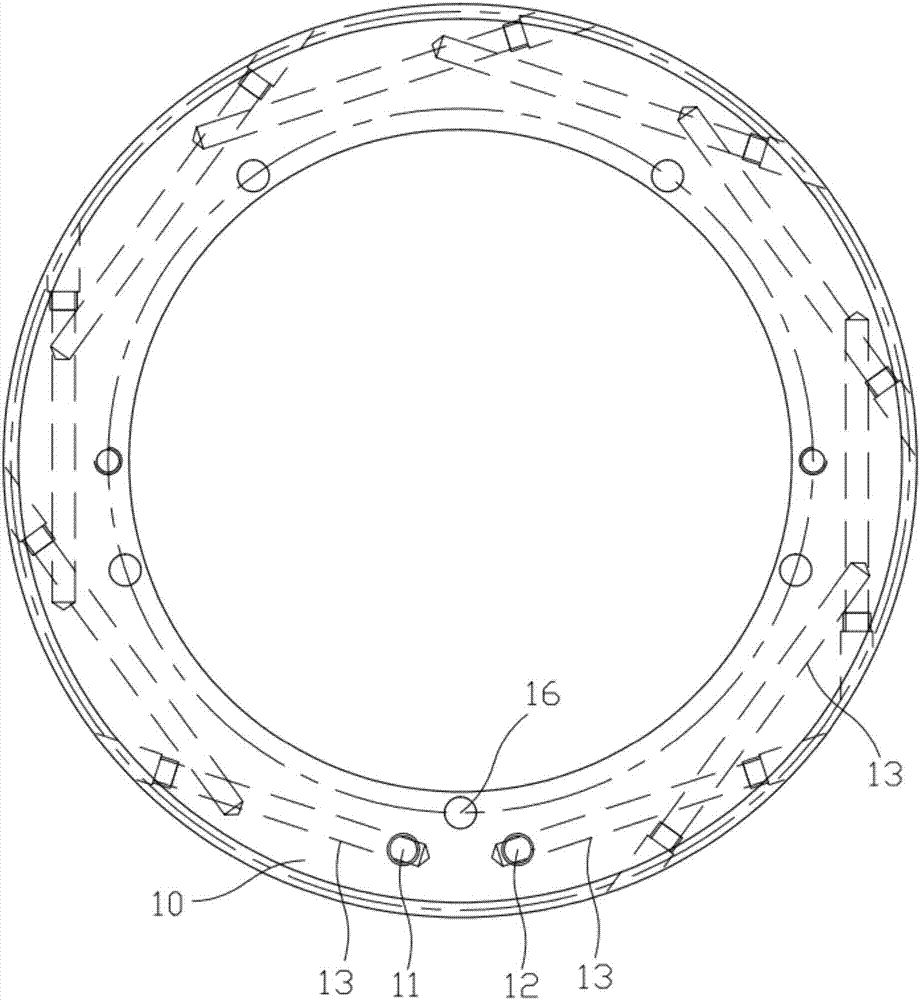

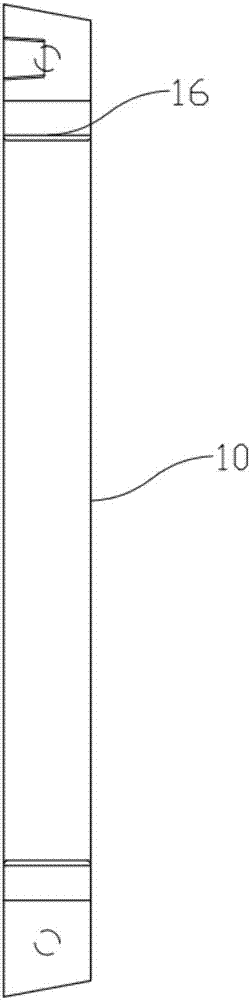

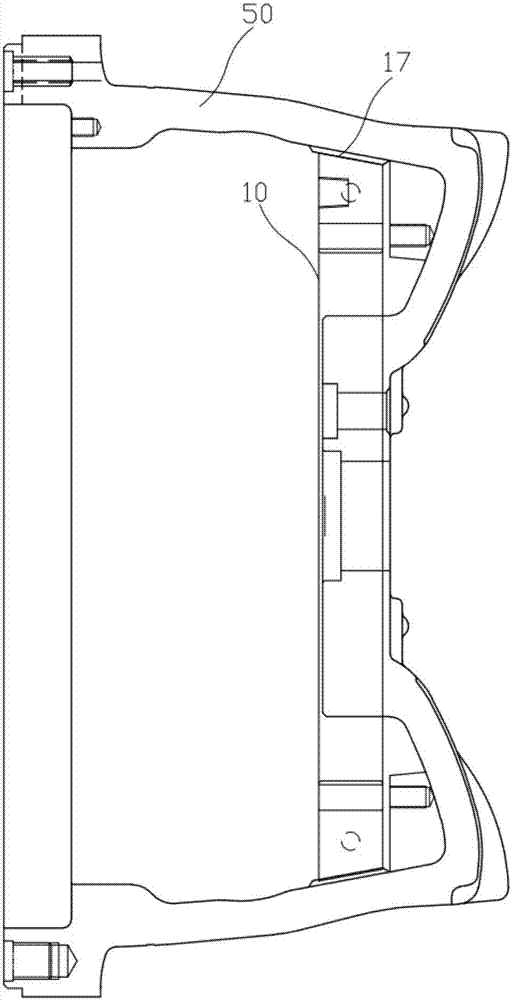

[0027] like Figures 1 to 3 As shown, the wheel hub mold tire ring water cooling device of the present invention is used to be installed at the hot node of the upper mold of the wheel hub mold (the area formed by the junction of the upper mold and the side mold is the hot node of the cast wheel hub), including The upper mold 50 of the mold is coaxial and can be installed on the ring-shaped tire ring body 10 at the thermal node of the upper mold 50. The tire ring body 10 is provided with a water inlet 11 and a water outlet 12 next to each other, and a water inlet 11 and an outlet connected to each other. The cooling water channel of the nozzle 12, and the cooling water channel is close to the outer wall of the tire ring body 10 in contact with the upper mold 50.

[0028] Specifically, the cooling water channel is formed by cross-connecting a plurality of long holes 13 drilled along the outer wall of the tire ring body 10 in turn, and the ends of the long holes 13 at the head an...

Embodiment approach 2

[0035] like Figures 4 to 6 As shown, the wheel hub mold tire ring water cooling device of the present invention is used to be installed at the hot node of the upper mold of the wheel hub mold (the area formed by the junction of the upper mold and the side mold is the hot node of the cast wheel hub), including The upper mold 50 of the mold is coaxial and can be installed on the ring-shaped tire ring body 20 at the thermal node of the upper mold 50. The tire ring body 20 is provided with a water inlet 21 and a water outlet 22 next to it, and a water inlet 21 and an outlet. The cooling water channel of the nozzle 22, and the cooling water channel is close to the outer wall of the tire ring body 20 in contact with the upper mold 50.

[0036] Specifically, the cooling water channel is an annular groove 23 recessed on the tire ring body 20 and coaxial with the tire ring body 20. The annular groove 23 is arc-shaped and its two ends are connected with the water inlet 21 and the water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com