Forging technique for cake forgings

A forging and process technology, which is applied to the forging field of large cake forgings, can solve the problems of uneven deformation of forgings, difficult deformation areas, and scrapped forgings, and achieve the effects of optimizing forging structure, improving deformation uniformity and reducing forming load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

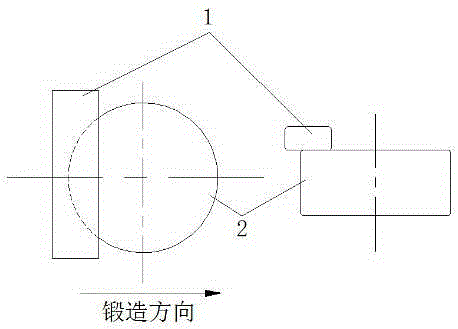

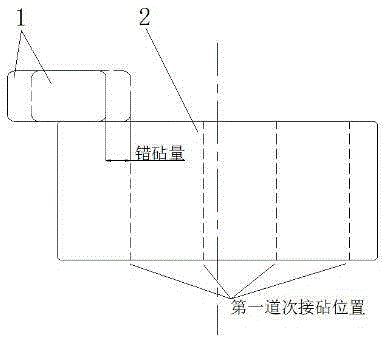

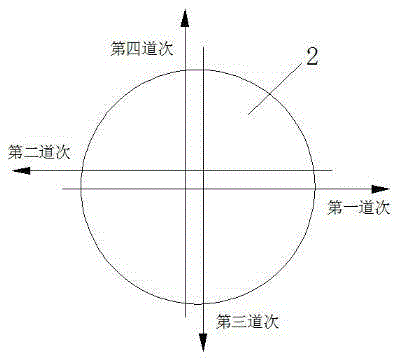

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

[0030] The present invention provides a kind of forging process of cake class forgings, and the method comprises the following steps:

[0031] Step 1: heating the forging to improve the plasticity of the forging and reduce the deformation resistance of the forging;

[0032] Step 2: Open the forging forging to improve the overall deformation uniformity of the forging and ensure uniform mechanical properties;

[0033] Step 3: Return to the furnace to heat the forging; when the temperature of the forging is lower than 800°C, stop forging and return to the furnace for heating;

[0034] Step 4: Forming to forge the ingot to the target forging shape;

[0035] Step 5: Carry out heat treatment on the forging after forging.

[0036] The specifications for the heated forging in step 1 are: the furnace loading temperature is 600°C, and it is kept at this temperature for 2 hour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com