Furnace temperature controlling method in heating process of plate blank of heating furnace

A technology of slab heating and control method is applied in the field of furnace temperature control in the slab heating process of a heating furnace, and can solve problems such as inability to comprehensively consider, inability to quantitatively, accurately and precisely control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

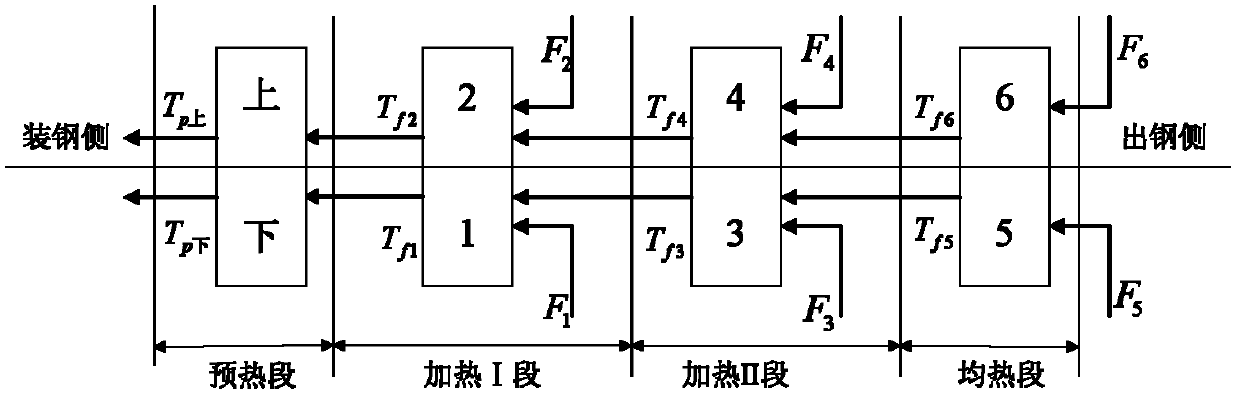

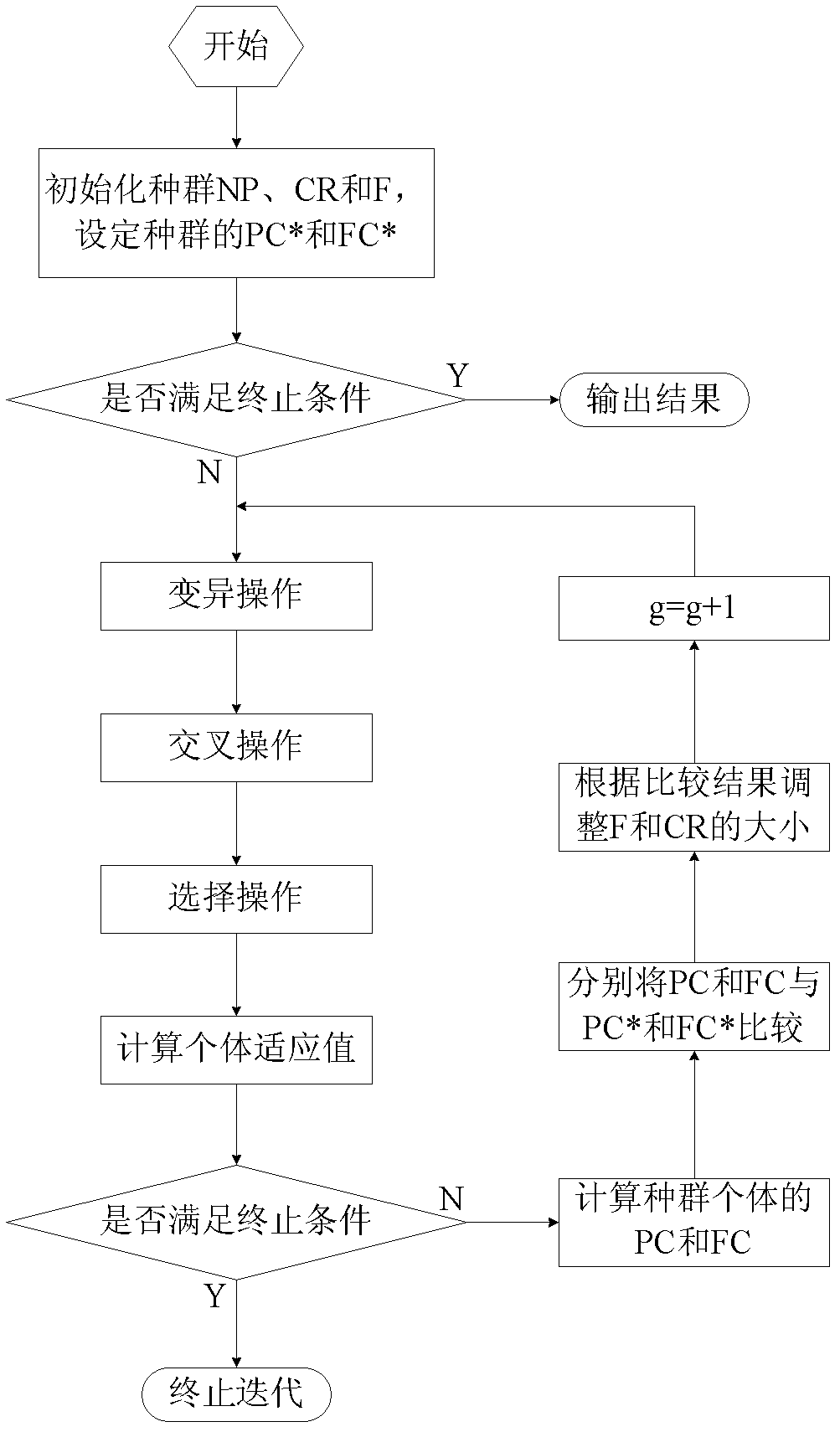

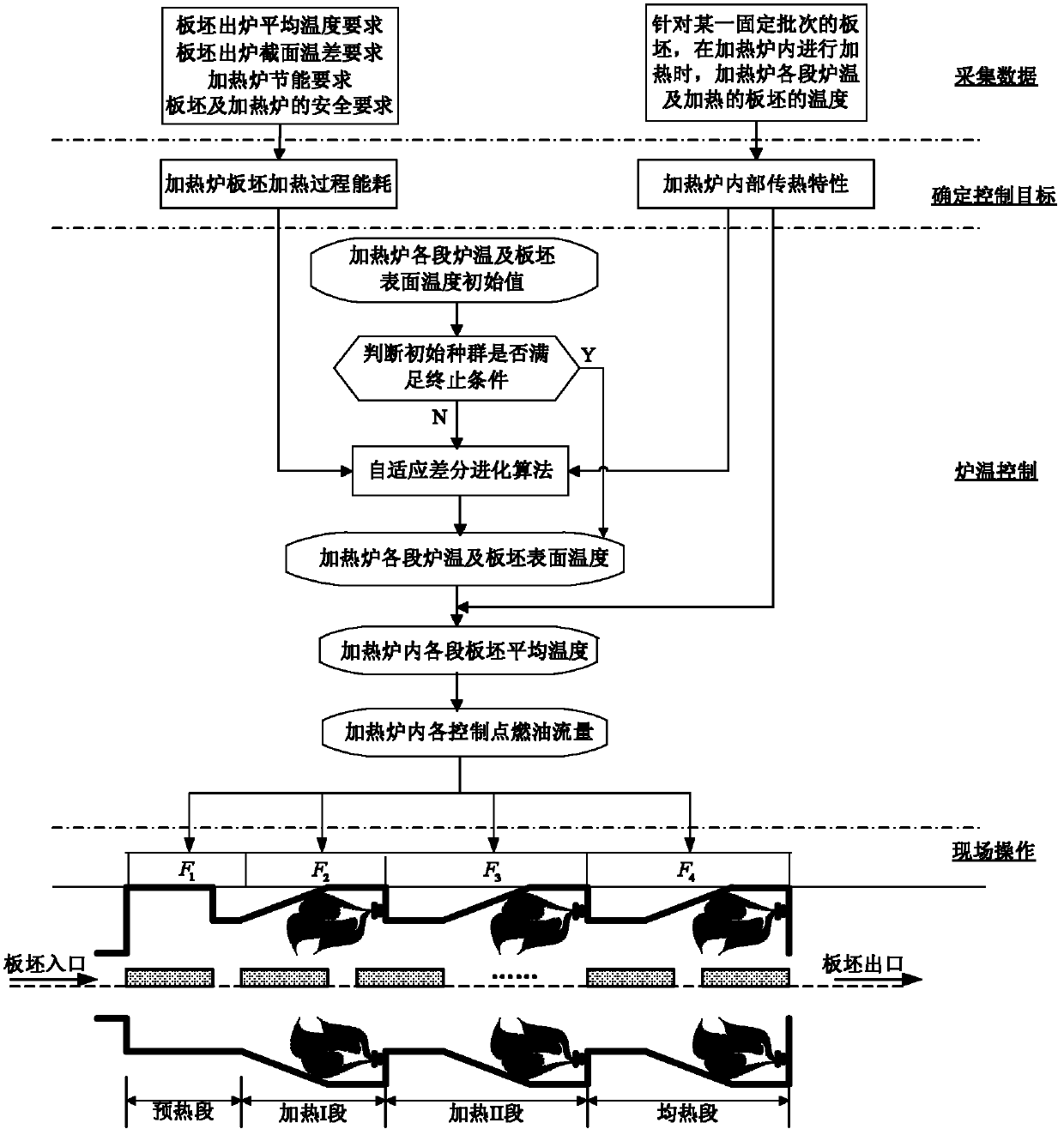

[0075] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0076] This embodiment is aimed at the heating furnace process stage of a certain iron and steel enterprise, and performs temperature control on the slab heating process of the heating furnace.

[0077] The control system used includes: a DELL OPTIPLEX 745 client computer; a lenovo M8000t server, a Huawei S5700-24TP-SI(AC) switch, and a TP-LINK TL-R406 router.

[0078] The collected data is as follows:

[0079] 1. Equipment parameters and raw material parameters: the effective length of the heating furnace is 35m, the inner width of the furnace is 9.4m, and the heating raw material is continuous casting billet;

[0080] 2. Slab specifications: thickness 130-220mm; width 650-1380mm; length 3700-8700mm; single slab weight 15-20.8t;

[0081]3. Operating parameters: The slabs in the furnace are arranged in a single row (long slab) or double row (short sla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com