Novel drying technical method for preparing supper absorbent resin

A technology of super absorbent resin and process method, applied in drying, drying machine, drying solid materials, etc., can solve the problems of poor consistency of product moisture content, poor process stability, and high labor cost, and ensure the consistency of moisture content. , Consistent product quality, the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

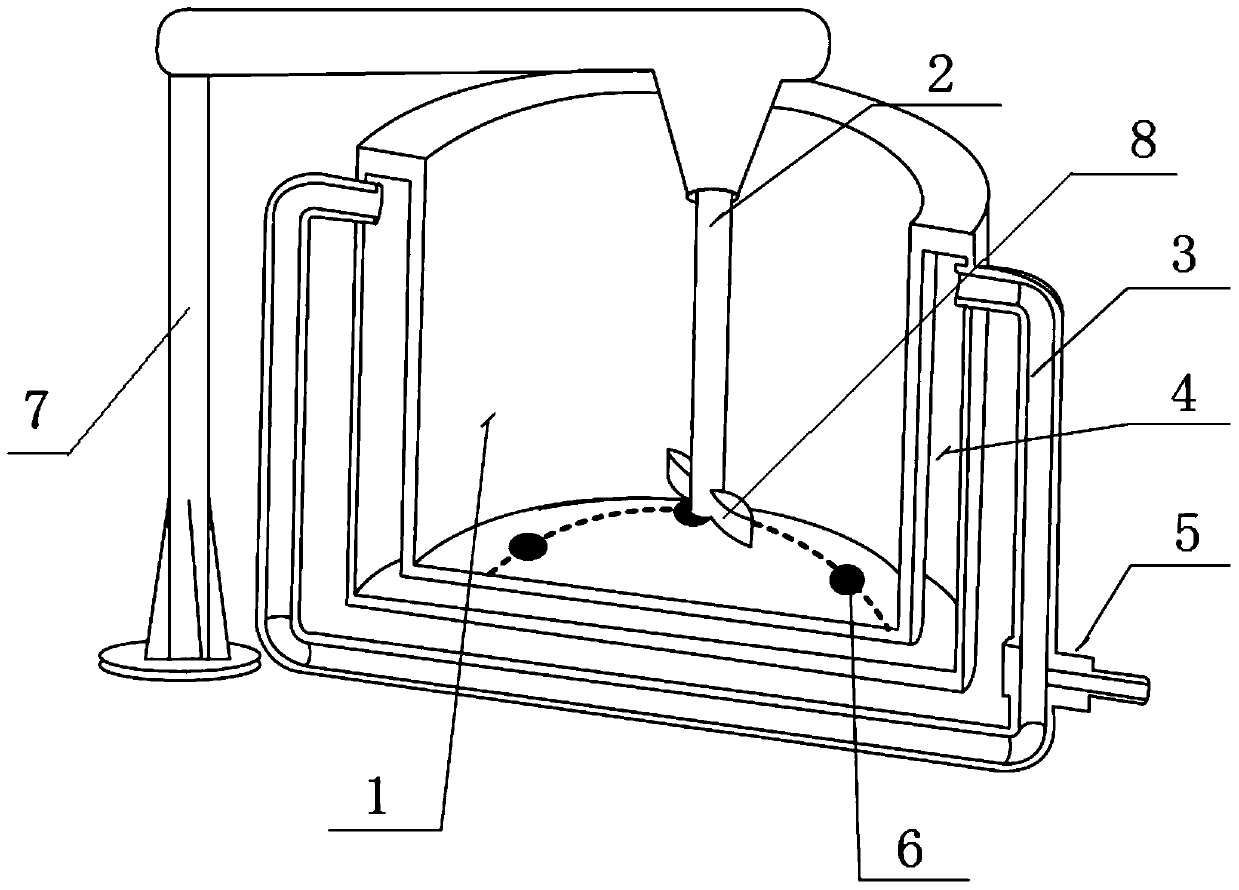

[0035] The present invention will be further described below according to the accompanying drawings.

[0036] A novel drying process method for preparing superabsorbent resin, the specific drying process steps are as follows:

[0037] S1: Put heat transfer oil into the heat transfer oil pipe of the oil bath drying device, and set the temperature of the heat transfer oil to 100~170°C;

[0038] S2: Pour vegetable oil into the oil bath drying device, and set the temperature of the vegetable oil to 90~120°C;

[0039] S3: Put the prepared superabsorbent resin into the oil bath separation box, and put the oil bath separation box into the vegetable oil of the oil bath drying device;

[0040] S4: Turn on the stirring paddle of the oil bath drying device, and set the speed of the stirring paddle to 10~15r / min;

[0041] S5: After drying for 1 hour, take out the oil bath separation box;

[0042] S6: subjecting the superabsorbent resin in the oil bath separation box to a centrifugal de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com