Synchronous electrical machine

A technology of synchronous motors and mechanical energy, applied in synchronous generators, synchronous machines, synchronous motors for single-phase current, etc., can solve problems such as generator complexity, reduce maintenance costs, reduce temperature gradients, and improve reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0091] The following examples are examples. Although the description herein refers to one or more embodiments, this does not necessarily mean that every reference refers to the same embodiment or that a feature applies to only one embodiment. Simple features of different embodiments can also be combined to provide other embodiments. In the drawings, for the sake of illustration and clarity, scale and proportion are not strictly adhered to.

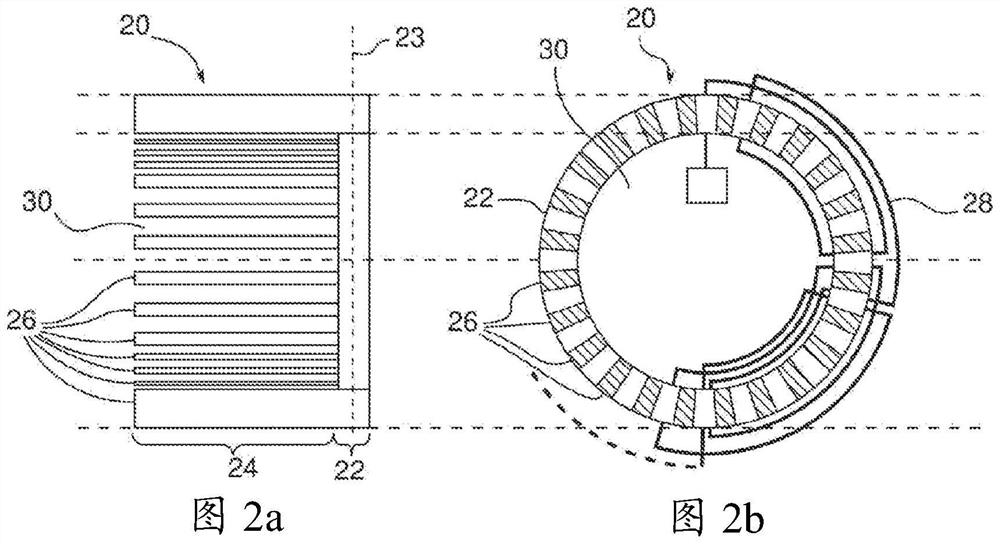

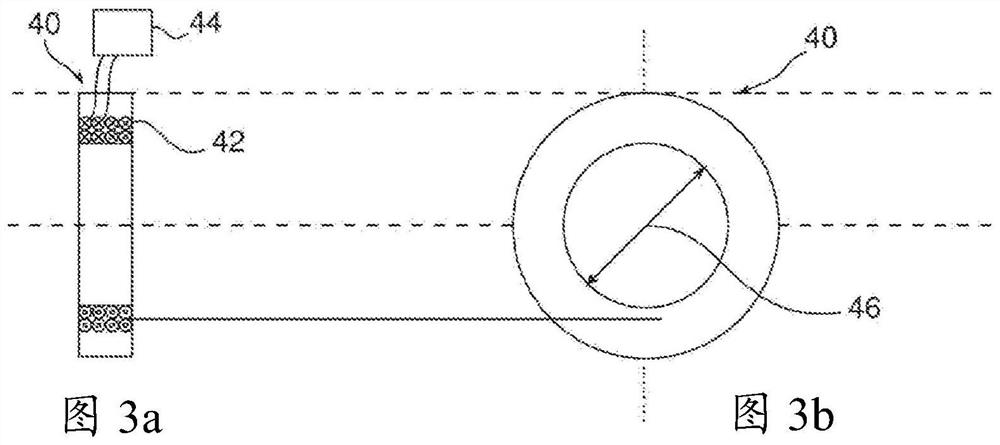

[0092] The following figures describe the components of a brushless and magnetless synchronous machine configured to drive a rotating element about the axis of rotation of the electric machine or from mechanical energy transmitted by the rotating element, according to embodiments of the present invention. generate electricity.

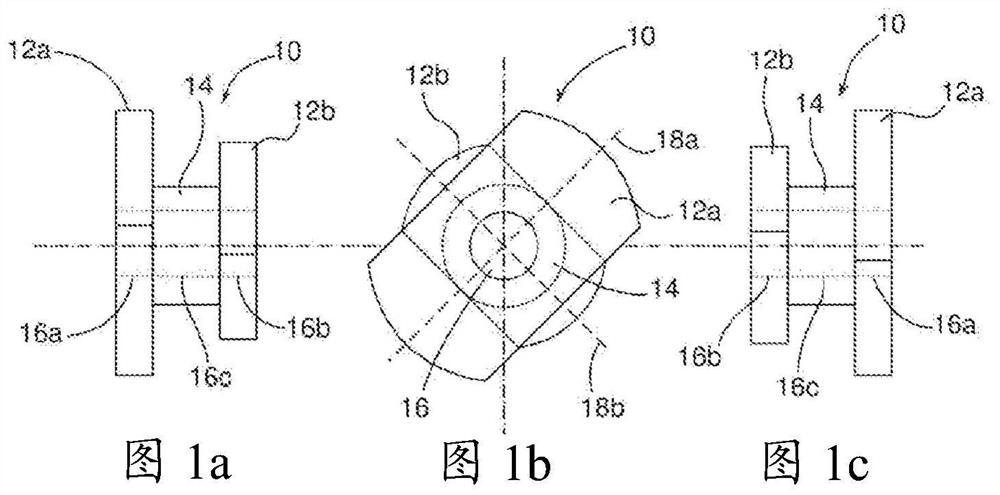

[0093] Figure 1a , Figure 1b and Figure 1c A rotor 10 of an electric machine according to an embodiment of the invention is shown schematically as seen from the right, from the front and from the left, resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com