a steam box

A technology of a steam box and a steam pipeline, which is applied in the field of the steam box, can solve the problems of unbalanced internal temperature, high steam temperature, and increased foaming reject rate, etc., and achieves the effects of improving the yield rate, facilitating secondary foaming, and increasing the temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

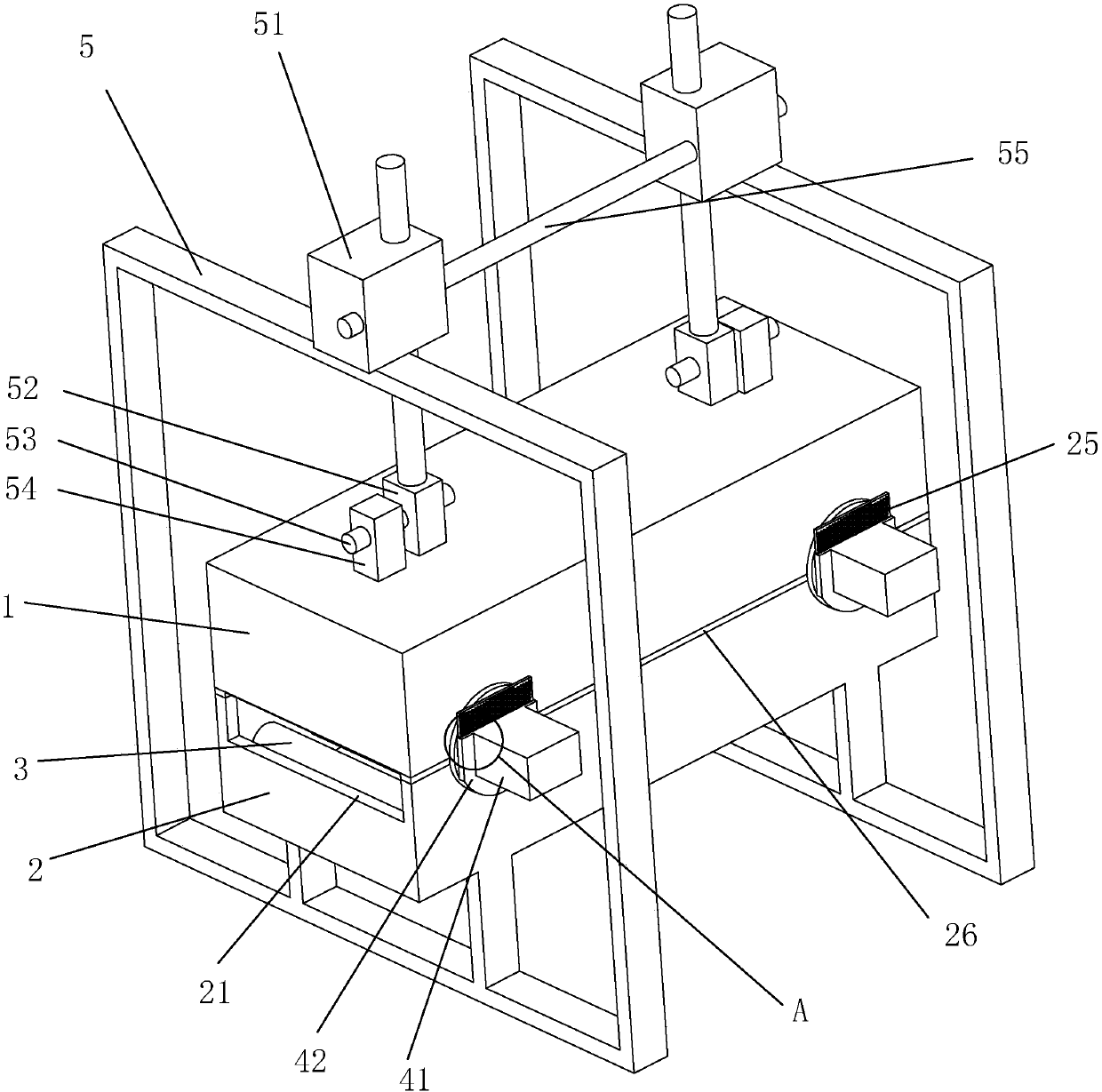

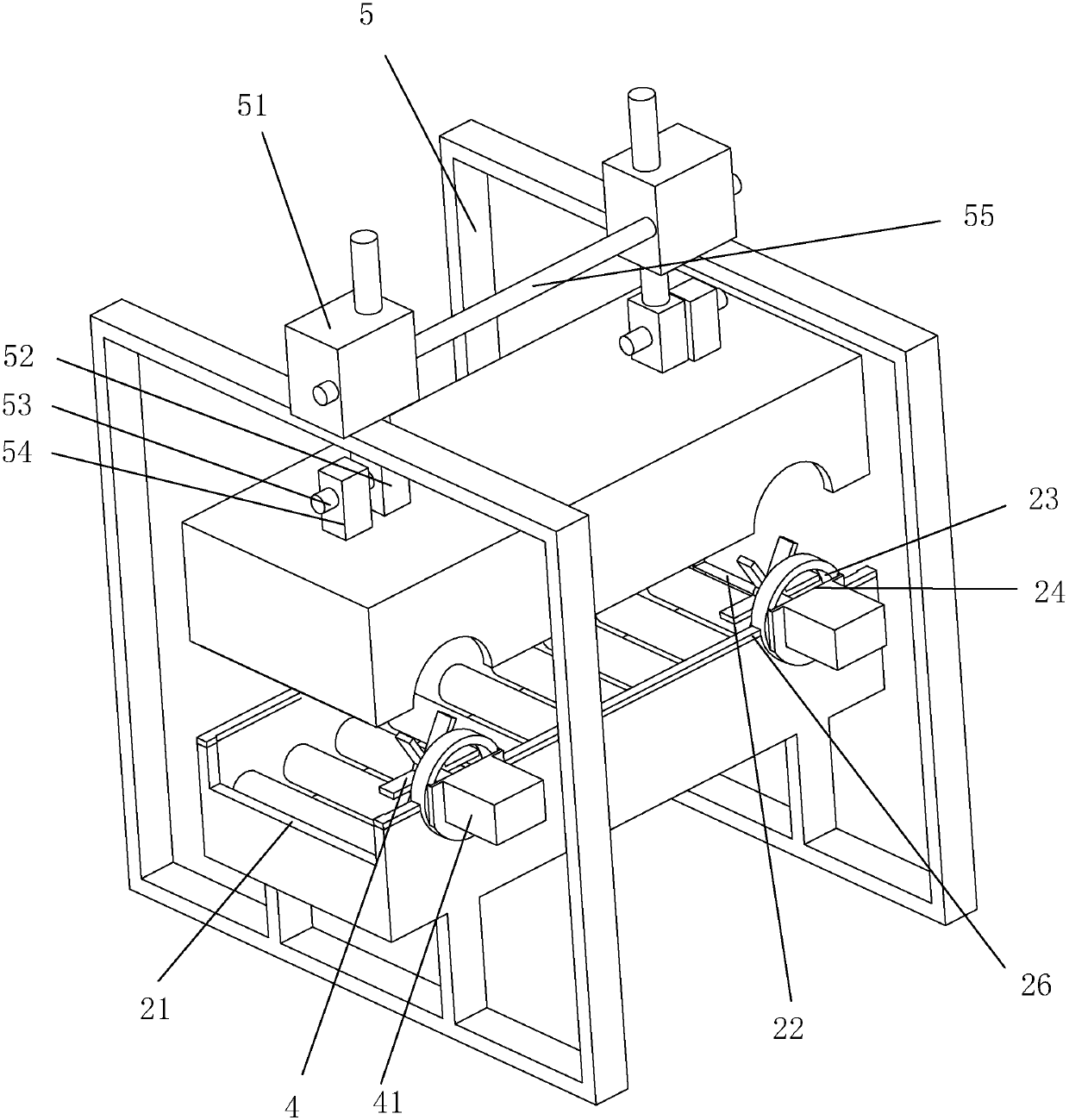

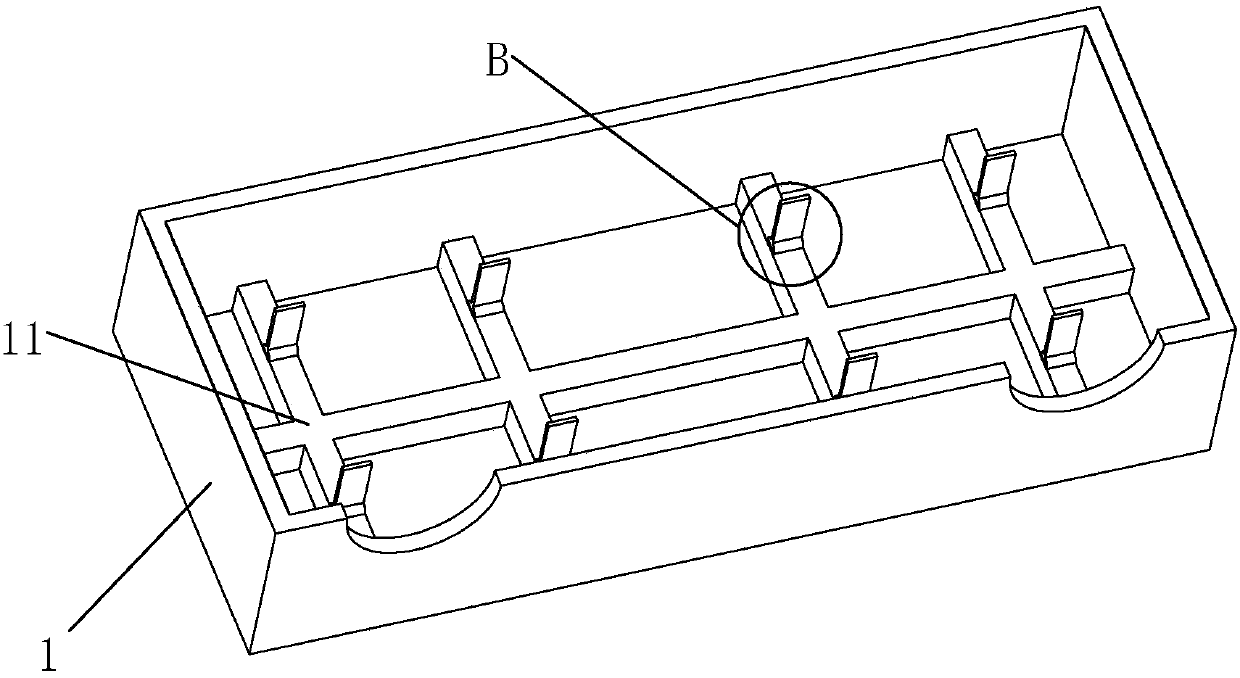

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0023] A steam box includes a box main body, a delivery roller 3, a steam pipe 11, a nozzle 12, and a heater. The two ends of the box main body are respectively provided with a feed end 21 and a discharge end 22. The heater, delivery roller 3 Both the steam pipe 11 and the steam pipe 11 are arranged in the main body of the box, the nozzle 12 is arranged on the steam pipe 11, the main body of the box is provided with an air supply mechanism, and the main body of the box is provided with an installation hole 23 for the installation of the air supply mechanism. The blower mechanism includes a fan blade 4 and a driving motor 41 , the fan blade 4 is arranged on the driving motor 41 , and the nozzle 12 is hinged on the steam pipe 11 .

[0024] After the preliminary processing of the foamed plastic board is completed, the foamed plastic board is inserted into the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com