Application of graphitization furnace to roasting process

A technology of graphitization furnace and roasting process, which is applied in the direction of inorganic chemistry, carbon compounds, carbon preparation/purification, etc. It can solve the problems of large-scale graphite crucible roasting process, low added value of products, high energy consumption cost, etc., and achieve reduction Energy cost, environmental protection, energy consumption reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

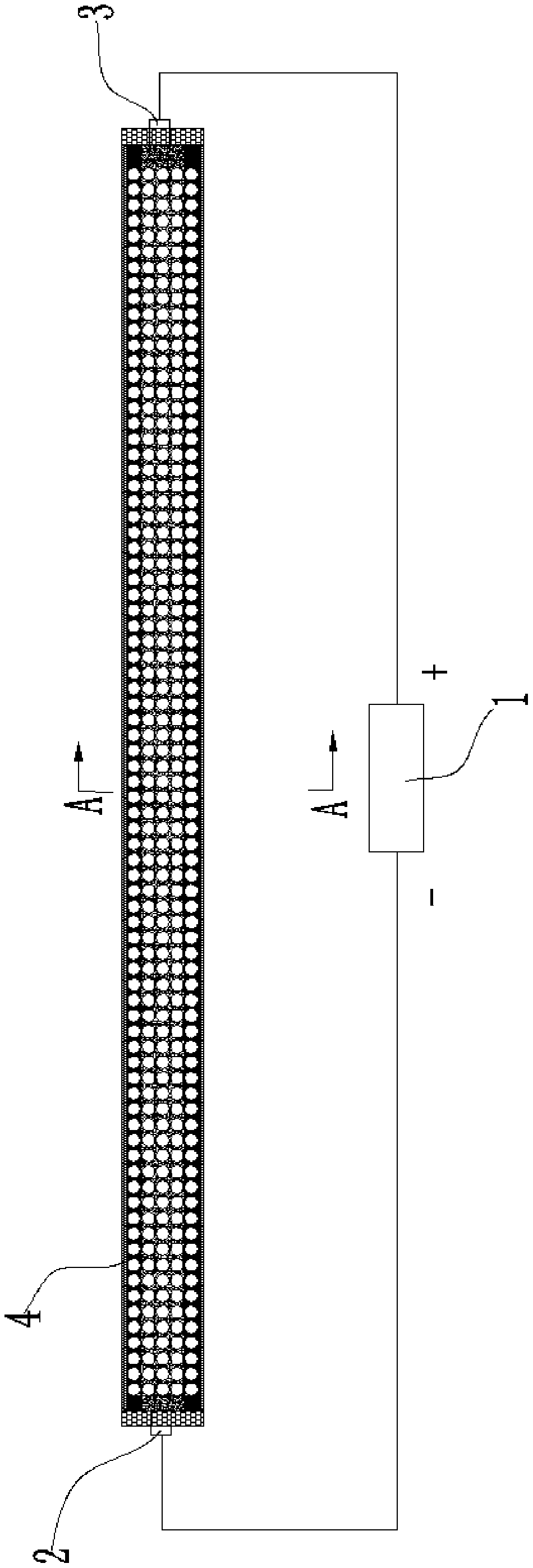

[0042] An application of a graphitization furnace on a roasting process, which is used for the roasting process of a graphite crucible, and the product 5 to be treated is a graphite crucible green body, and the specific steps include:

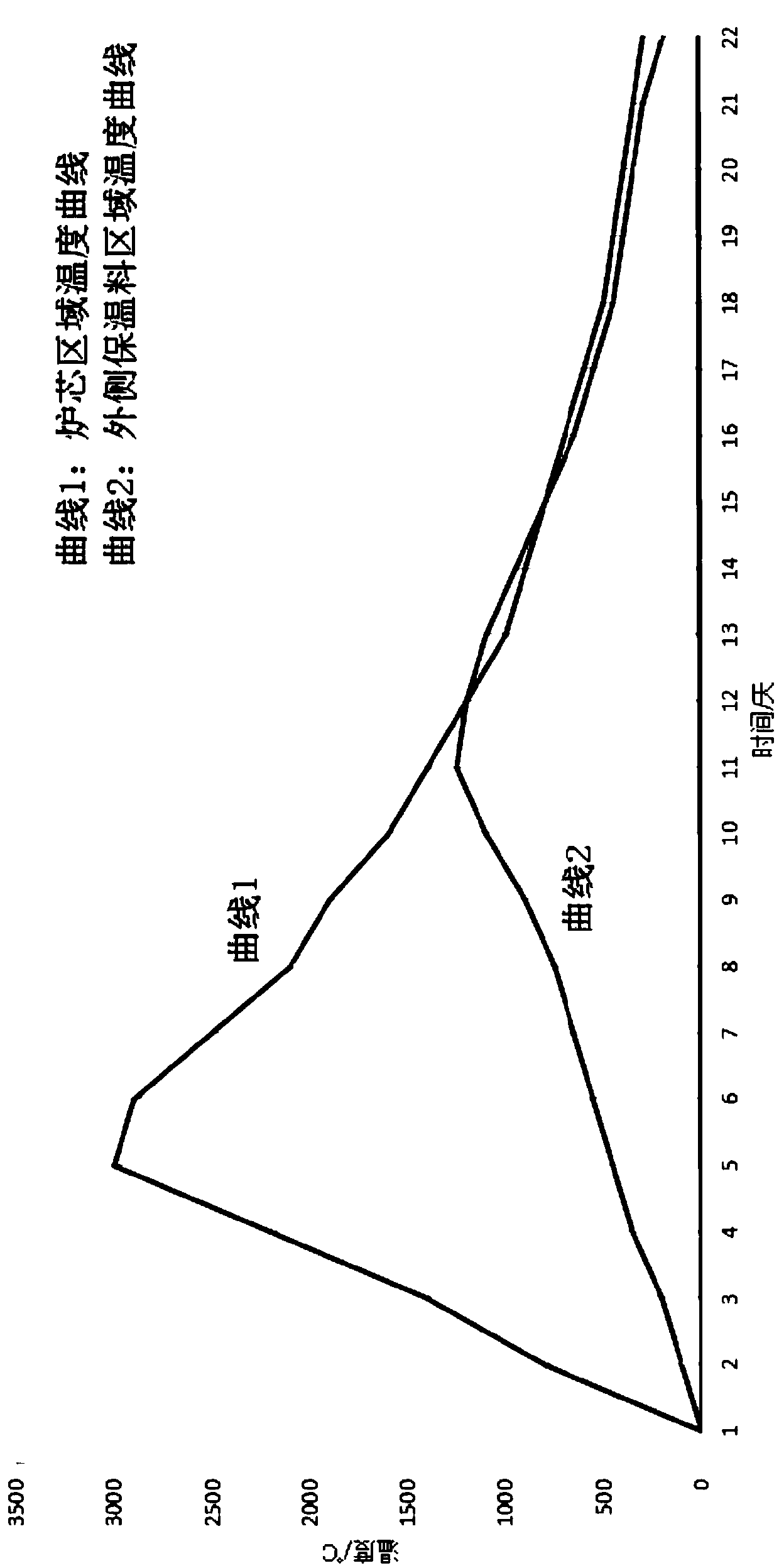

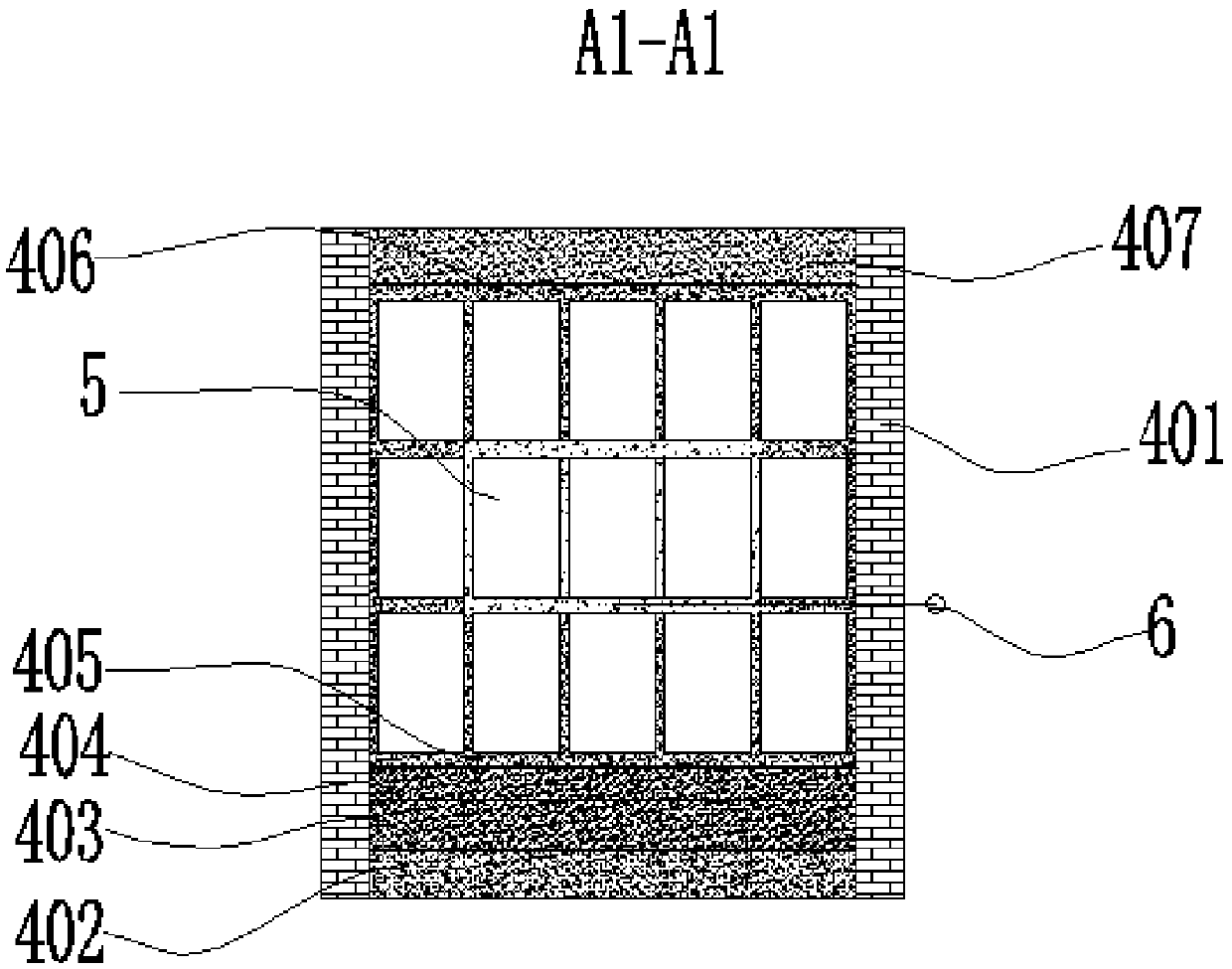

[0043] a. Furnace loading: Lay a 300mm quartz sand cushion 402, a 300mm carbon black cushion 403 and a 200mm thermal insulation cushion 404 in the bottom-up sequence of the furnace body 4, above the thermal insulation cushion 404 Lay the first resistance material layer 405 with a thickness of 80-120mm, divide the graphite crucible green bodies into 5 rows, place them in parallel above the first resistance material layer 405, place the graphite crucible green bodies in the middle three rows vertically, and place them on the outermost When the graphite crucible green body is laid, the top is tilted outward, and the inclination angle a is 45-60°. The interior of the graphite crucible green body and between each other are filled with resistance mate...

Embodiment 2

[0049] A kind of application of graphitization furnace about roasting process, used for the roasting process of graphite crucible, with embodiment 1, the difference is: the distance between front and back, left and right between graphite crucible green bodies is 100mm, the upper and lower intervals between graphite crucible green bodies The distance is 120mm, and the resistance material uses calcined petroleum coke with a sulfur content of 2.5% to 2.8%; the particle size of the resistance material is: 4 to 16mm, and the density of the calcined petroleum coke is 0.8 to 1.0g / cm 3 , the thermal insulation material is calcined petroleum coke, and the particle size of the calcined petroleum coke used in the thermal insulation material is 0-1mm; the heating rate in the range of 0-300°C is 11°C / hour, and the heating rate in the range of 300-750°C is 5°C / hour Hours, the heating rate in the range of 750-1200°C is 11°C / hour, the total power transmission time is 7 days, and the cooling ti...

Embodiment 3

[0051] A kind of application of graphitization furnace about roasting process, used for the roasting process of graphite crucible, with embodiment 1, the difference is: the distance between front and back, left and right between graphite crucible green bodies is 80mm, the upper and lower intervals between graphite crucible green bodies The distance is 80mm, and the resistance material uses the particle size coke after the broken anode with a sulfur content of 3.3%~3.5%. The particle size of the resistance material is 15~30mm, and the particle size coke after the broken anode is 1~1.2g / cm 3 , the thermal insulation material is calcined petroleum coke, and the particle size of the calcined petroleum coke used in the thermal insulation material is 1-2 mm; the heating rate in the range of 0-300 °C is 9 °C / hour, and the heating rate in the range of 300-750 °C is 3 °C / hour Hours, the heating rate in the range of 750~1200℃ is 9℃ / hour, the total power transmission time is 10 days, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com