Flame-retardant PBT/PA alloy material and preparation method thereof

A technology of alloy materials and composite materials, which is applied in the field of environmentally friendly polymer materials, can solve the problems that electronic capacitor parts cannot be used, and achieve the effects of improving compatibility and increasing the temperature of the glow wire.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

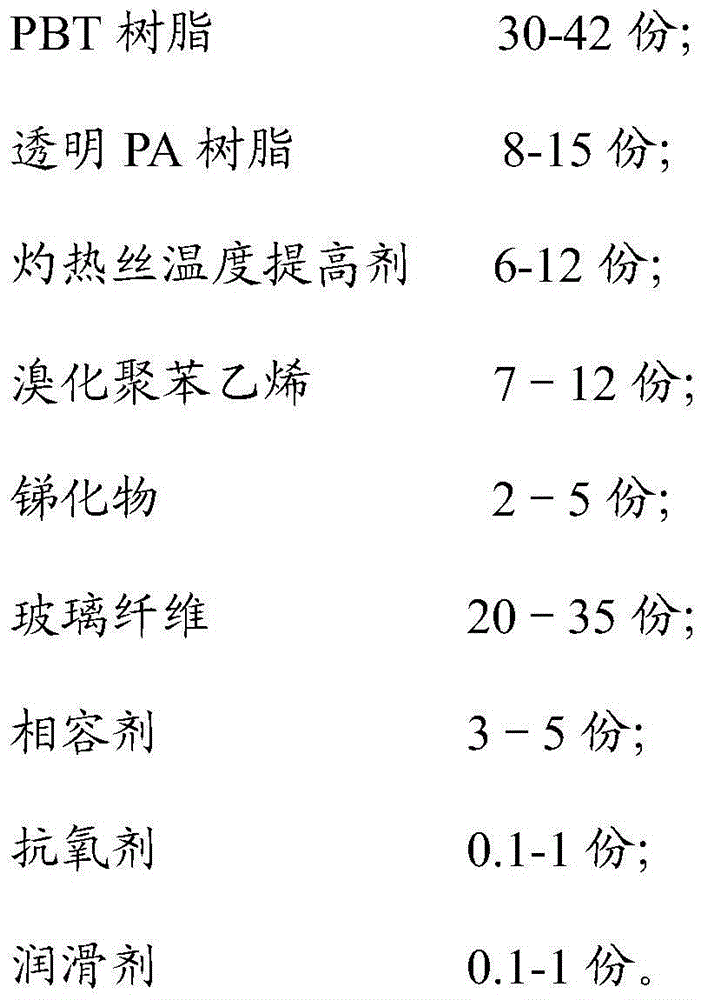

Method used

Image

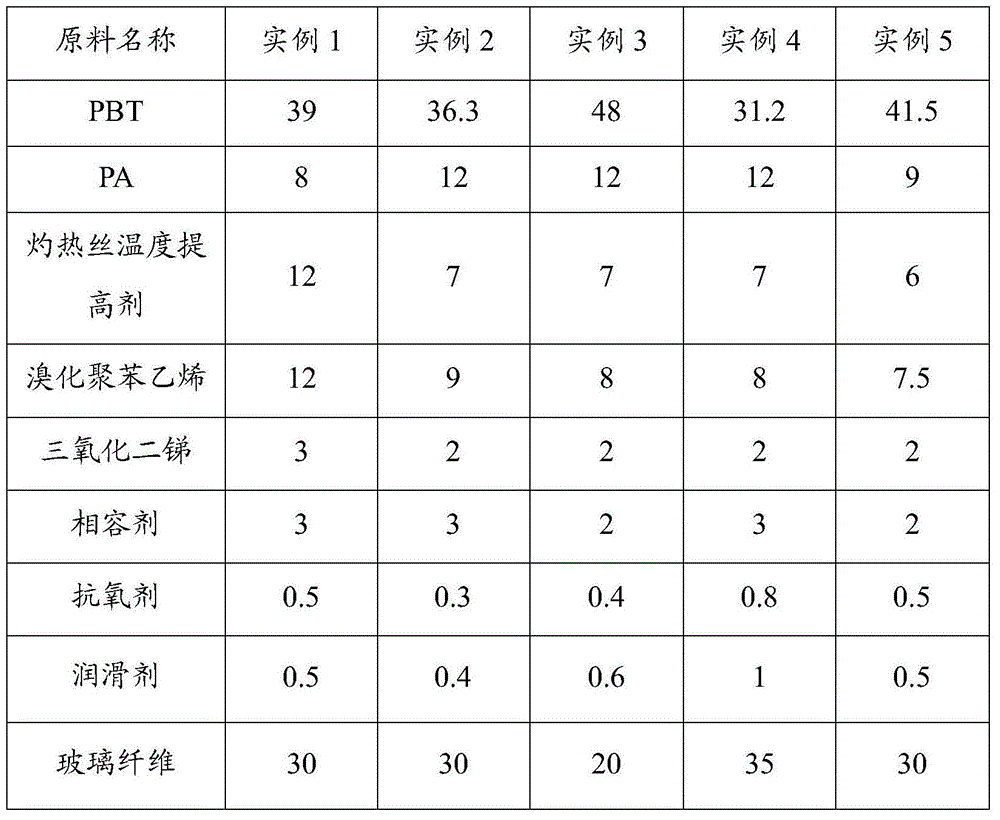

Examples

preparation example Construction

[0027] In addition, the embodiment of the present invention also provides a method for preparing a flame-retardant PBT / PA alloy material, comprising the following steps:

[0028] (1) take each raw material according to the raw material mass portion proportioning of the flame-retardant PBT / PA alloy material as described in any one of claims 1-9;

[0029] (2) Mix the weighed PBT resin, transparent PA resin, glow wire temperature raising agent, brominated polystyrene, antimonide, compatibilizer, antioxidant, and lubricant in a medium speed mixer for 3-5 minutes ;

[0030] (3) The mixed raw materials are put into the twin-screw extruder and fed through the main feeding port, and the glass fiber is added from the side feed, and melted and extruded to granulate; the process conditions of the twin-screw extruder It is: the temperature of the first zone of the twin-screw extruder is 230-240°C, the temperature of the second zone is 225-250°C, the temperature of the third zone is 220-2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com