Polymer coarse fibre used for concrete and preparation method

A crude fiber and polymer technology, applied in the field of polymer crude fiber and preparation, can solve the problems of limited anchoring and sliding energy consumption, increase porosity, reduce mechanical properties, etc., and achieve good macroscopic reinforcement and toughening effect, Effect of increasing pull-out resistance and improving interface performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Dry the polypropylene resin to a constant weight and add it to a twin-screw extruder. After melting, it is extruded through a circular spinneret hole. The temperature settings of each zone of the screw are as follows:

[0031] a district

Second District

Third District

Four districts

five districts

District six

150℃

200℃

220℃

225℃

230℃

220℃

220℃

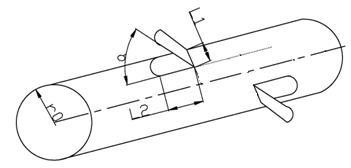

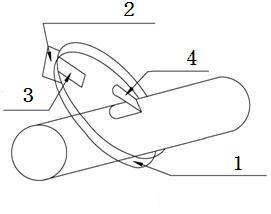

[0032] After the filaments are cooled with cooling water, they are stretched in three stages at 85-135°C, and the total draw ratio is 7.5 times. After the stretching is completed, use a cutter to cut out the anchoring sheet on the surface of the thread. The method of cutting the anchoring sheet in this embodiment is: pass the thread through a pipeline-type anchoring sheet cutting device, which has a series of circumferential supports , the thread continues to move axially forward after passing through the ring support, the base of the ...

Embodiment 2

[0035] Dry the polypropylene resin to a constant weight and add it to the twin-screw extruder. After melting, it is extruded through a circular spinneret hole. The set temperature of each zone of the screw is as follows:

[0036] a district

[0037]After the filaments are cooled with cooling water, they are stretched in two stages at 85-135°C, and the total draw ratio is 5.8 times. After the stretching is completed, use a cutter to cut out the anchoring piece on the surface of the thread. The cutting method of the anchoring piece is the same as that in Example 1. After cutting out the anchoring piece, heat-set the thread at 110°C, and finally cut it into a length of 60mm thick polymer fiber. The fiber radius (r0) is 0.6mm, the width L1 of the anchoring piece is 100% of the radius (r0), which is 0.6mm, the length L2 of the anchoring piece is 100% of L1, which is 0.6mm, and the axial clamping between the anchoring piece and the thick fiber Angle a is 15°. This crude...

Embodiment 3

[0039] Dry the polymethyl methacrylate resin to a constant weight and add it to a twin-screw extruder. After melting, it is extruded through a square spinneret hole. The set temperature of each zone of the screw is as follows:

[0040] a district

[0041] After the filaments are cooled with cooling water, they are stretched in five stages at 70-130°C, and the total draw ratio is 10 times. After the stretching is completed, use a cutter to cut out the anchoring piece on the surface of the thread. The cutting method of the anchoring piece is the same as that in Example 1. After cutting out the anchoring piece, heat-set the thread at 100°C, and finally cut it into a length of 40mm thick polymer fiber. The fiber radius (r0) is 0.2mm, the width L1 of the anchoring piece is 80% of the radius (r0), which is 0.16mm, and the length L2 of the anchoring piece is 110% of L1, which is 0.176mm. The axial clamping between the anchoring piece and the thick fiber The angle a is 20°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com