Boron carbide-titanium alloy composite armour

A titanium alloy and boron carbide technology is applied in the field of boron carbide-titanium alloy composite armor, achieving the effects of simple process, mutual attraction avoidance, and mature technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Example 1 Preparation of boron carbide ceramic sheet

[0020] Step 1) Raw material powder: choose boron carbide powder with an average particle size of 3-5 um as the raw material, add 3%-4% graphite powder as a sintering aid, and the average particle size of the graphite powder is 1-2 um;

[0021] Step 2) Prepare graphene solution: prepare 1-2 wt% graphene aqueous solution or alcohol solution, add N-methylpyrrolidone as a dispersant, and ultrasonically disperse for 10-20 h to obtain a uniformly dispersed graphene solution; where graphene The sheet diameter > 1um, the number of layers < 10 layers, and the amount of graphene added accounts for 1-5 wt% of the boron carbide powder;

[0022] Step 3) Put the powder obtained in step 1) and the graphene solution obtained in step 2) into a ball mill and mill for 8-10 hours, the speed of the ball mill is 30-50rpm, and the ball-to-material ratio is 2:1;

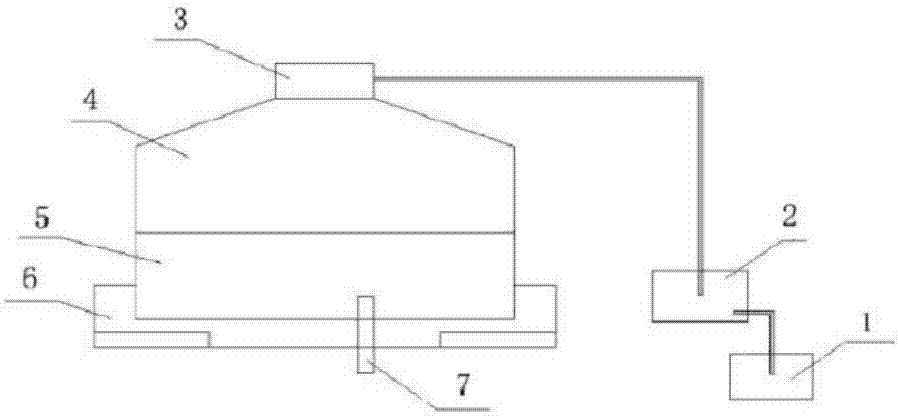

[0023] Step 4) Granulation: as in figure 1 Shown, adopt granulator, granul...

Embodiment 2

[0026] Example 2 Boron carbide-titanium alloy composite armor

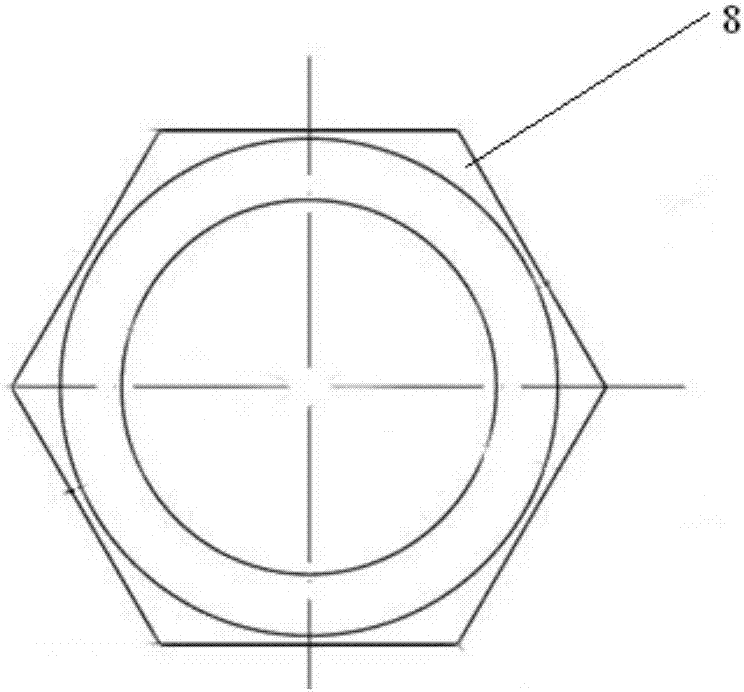

[0027] Step 1) According to the preparation method of Example 1, and the graphite mold in Step 5) of Example 1 is a regular hexagon, such as figure 2 As shown, a regular hexagonal ceramic sheet is obtained, and the ceramic sheet 8 is spliced together to form a ceramic plate 11 .

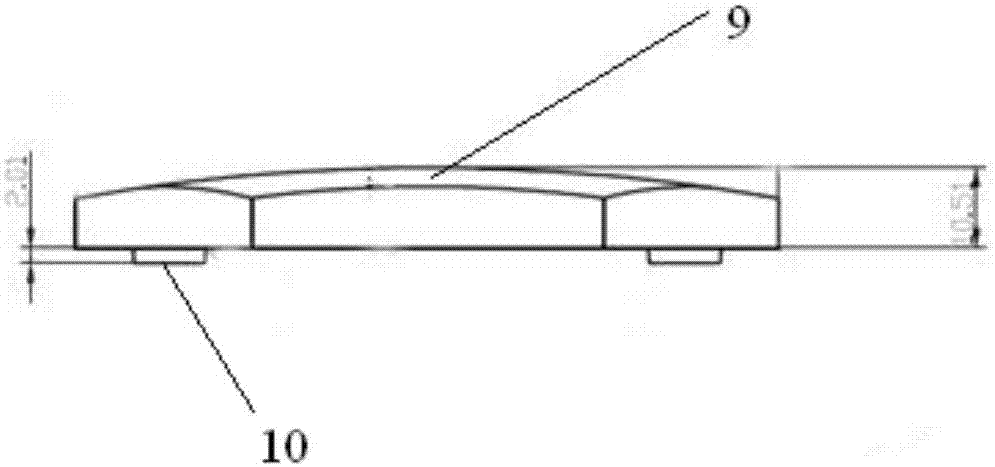

[0028] Step 2) First, prefabricate a mold of a certain shape according to the size of the boron carbide ceramic plate 11, place the ceramic plate 11 to be poured in the mold, preheat it in a 400°C oven for 1 hour, take it out and place it in the pouring tank. Then the melting furnace is heated to a certain temperature. After the titanium alloy is completely melted, it is cast around the ceramic block. After the molten titanium alloy solidifies, the metal-to-ceramic material is packaged to form an overall structure of titanium alloy wrapped boron carbide ceramics. The amount of titanium alloy is calculated according to the pouring siz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com