Preparation method of flame-retardant low-smoke polystyrene composite

A technology of polystyrene and composite materials, applied in the field of polystyrene, can solve the problems of poor flame retardancy of polystyrene, achieve the effects of improving flame retardancy, reducing production costs, and strengthening interface bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

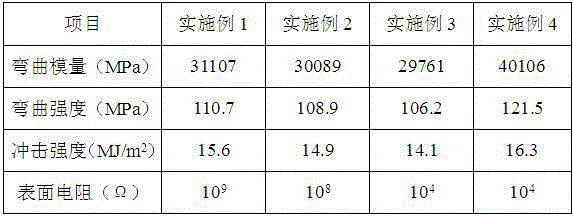

Examples

Embodiment 1

[0024] A method for preparing a flame-retardant low-smoke polystyrene composite material, comprising the following steps: Step 1: Take styrene and a dispersant with a volume ratio of 1:0.2 in sequence, and weigh the ratio of the weight to the volume of styrene to be 0.025g : 1 mL of benzoyl peroxide, the ratio of weight to volume of styrene is 0.4 g: 1 mL of bis(2,3-dibromopropyl) fumarate, styrene, dispersant, benzene peroxide After mixing formyl and bis(2,3-dibromopropyl)fumarate, stir at room temperature for 30 minutes, then heat and stir in a water bath at 85°C for 2 hours, filter and dry to obtain polystyrene barrier Burn the substrate and keep it for later use; stir at room temperature for 30 minutes before heating up, and keep the stirring speed constant throughout the reaction to avoid incomplete reaction.

[0025] Step 2. According to the volume ratio of 1:4:0.03, weigh ethanol, water and divinylbenzene and mix them sequentially to prepare a mixed solution A, and add ...

Embodiment 2

[0032] A method for preparing a flame-retardant low-smoke polystyrene composite material, comprising the following steps: Step 1: Take styrene and a dispersant with a volume ratio of 1:0.2 in sequence, and weigh the ratio of the weight to the volume of styrene to be 0.025g : 1 mL of benzoyl peroxide, the ratio of weight to styrene volume is 0.4 g: 1 mL of bis(2,3-dibromopropyl) fumarate, styrene, dispersant, benzene peroxide After mixing formyl and bis(2,3-dibromopropyl)fumarate, stir at room temperature for 30 minutes, then heat and stir in a water bath at 90°C for 1.5 hours, filter and dry to obtain polystyrene Flame retardant matrix, spare;

[0033] Step 2. According to the volume ratio of 1:4:0.03, weigh ethanol, water and divinylbenzene and mix them sequentially to prepare a mixed solution A, and add styrene monomer, acrylic acid monomer and persulfuric acid to the mixed solution in sequence ammonium, to prepare the mixed solution B. At room temperature, the mixed soluti...

Embodiment 3

[0039] A method for preparing a flame-retardant low-smoke polystyrene composite material, comprising the following steps: Step 1: Take styrene and a dispersant with a volume ratio of 1:0.2 in sequence, and weigh the ratio of the weight to the volume of styrene to be 0.025g : 1 mL of benzoyl peroxide, the ratio of weight to styrene volume is 0.4 g: 1 mL of bis(2,3-dibromopropyl) fumarate, styrene, dispersant, benzene peroxide After mixing formyl and bis(2,3-dibromopropyl)fumarate, stir at room temperature for 30 minutes, then heat and stir in a water bath at 89°C for 1.9 hours, filter and dry to obtain polystyrene Flame retardant matrix, spare;

[0040] Step 2. According to the volume ratio of 1:4:0.03, weigh ethanol, water and divinylbenzene and mix them sequentially to prepare a mixed solution A, and add styrene monomer, acrylic acid monomer and persulfuric acid to the mixed solution in sequence ammonium, to prepare the mixed solution B. At room temperature, the mixed soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com