Novel non-autoclaved concrete brick and binder thereof

A concrete brick, autoclaved technology, applied in the field of building materials, can solve the problems of less seawater aggregate concrete, poor bonding performance, high cost, etc., and achieve the effect of reducing the amount of mortar, small strength dispersion, and low elastic modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

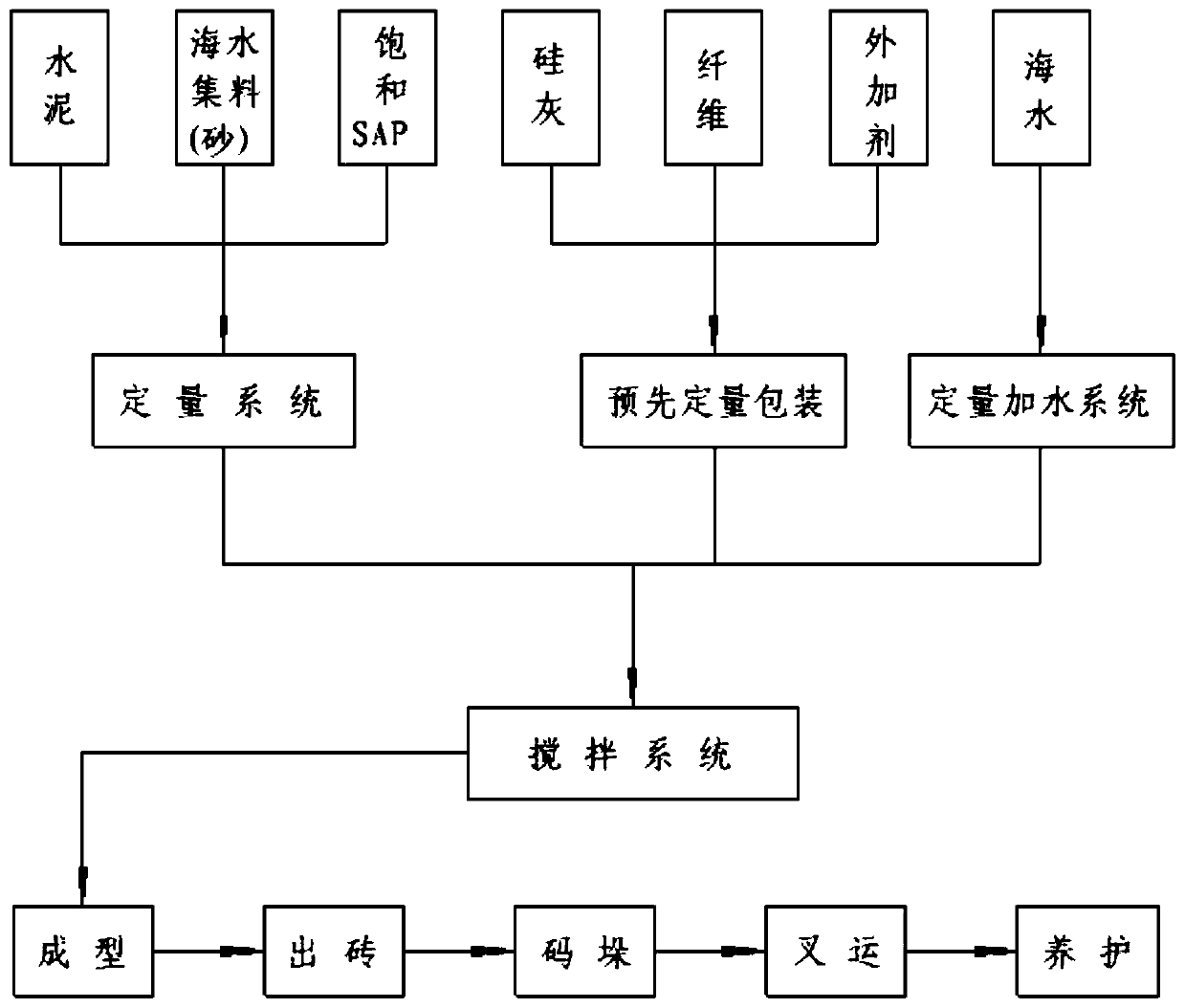

[0037] Such as figure 1 As shown, the preparation method of the novel autoclaved concrete brick that the embodiment of the present invention provides comprises:

[0038] ① Measuring and feeding

[0039] It can add cement, admixture, river sand (or coral sand) and seawater according to the set proportion and measure them. The cement and saturated SAP in this system are batched by the batching system by controlling their respective discharge time, the sand is batched quantitatively by the bucket truck, and the others are measured and loaded manually.

[0040] ② Stirring and conveying

[0041] It can mix the raw materials according to the preset mixing process to produce the concrete material (a dry and hard concrete mixture) required for prefabricated bricks. Lift and convey the stirred preformed material into the storage hopper.

[0042] ③Prefabricated

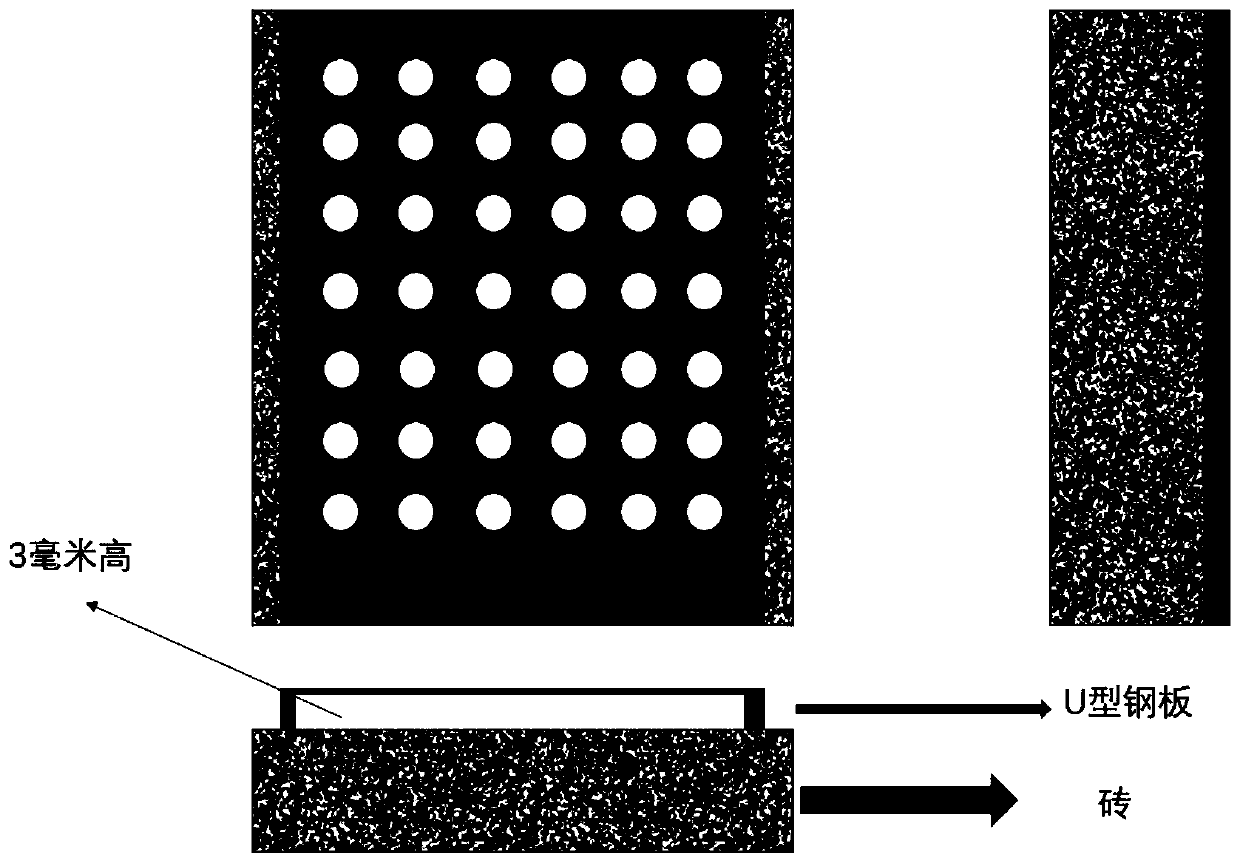

[0043] A steel mold that meets the national industry standard specifications is used to let the material into the mold, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com