Solar silicon wafer cutting method

A technology of solar silicon wafers and cutting methods, which is applied to working accessories, fine working devices, stone processing equipment, etc., can solve the problems of poor dispersion effect of mortar, reduced adsorption amount, and easy settlement, etc., to reduce the processing cost of silicon wafers , the fluctuation value is reduced, and the effect of reducing the amount of mortar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1, a kind of solar silicon chip cutting method of the present invention, comprises the following steps,

[0025] A. The cutting steel wire moves at high speed, so that the cutting mortar attached to the cutting steel wire acts on the lower surface of the silicon rod to be cut with a stable cutting force field, and the silicon rod moves from top to bottom to generate pressure on the cutting steel wire;

[0026] B. The cutting mortar dropped during the cutting process is recovered from the mortar tank under the cutting steel wire, and the stirring continues to be pumped to the nozzle, which continues to spray onto the cutting steel wire through the nozzle;

[0027] C. After the silicon rod is cut, the cutting mortar in the mortar tank is first introduced into the ultrasonic oscillator and then passed through the centrifuge to separate and recover silicon carbide and separation liquid;

[0028] D. Separate the separating liquid through a filter press; decoloriz...

Embodiment 2

[0059] Embodiment 2, a solar silicon wafer cutting method, the cutting mortar includes primary silicon carbide, recycled silicon carbide, primary cutting fluid and recycled cutting fluid, the mass ratio of primary silicon carbide and recycled silicon carbide is 4:6-0:10, By adding raw cutting fluid and recycled cutting fluid at a mass ratio of 1:1-3:7, the mortar density can reach 1.625-1.635kg·L -1 .

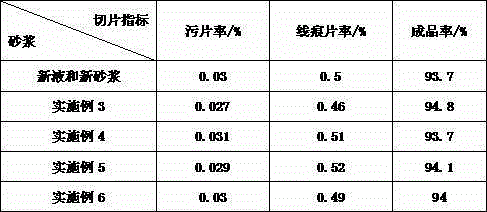

Embodiment 3

[0060] Embodiment 3, a solar silicon wafer cutting mortar, the mass ratio of primary silicon carbide and recycled silicon carbide used once is 1:9-0:10, and the mass ratio of adding primary cutting fluid to recycled cutting fluid is 1 :1-2:8, make the mortar density reach 1.625-1.635kg·L -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Power density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com