Wear resistant zinc alloy material and preparation method thereof

A technology of zinc alloy and metal wire, which is applied in the field of wear-resistant zinc alloy materials and its preparation, can solve problems such as complex processes, and achieve the effects of simple preparation process, convenient industrial production, and low material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

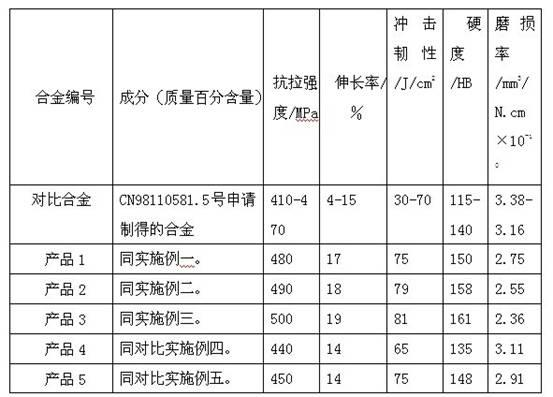

Examples

Embodiment 1

[0026] Zinc alloy matrix composition by weight percentage: Al is 41%, Sr is 0.2%, Si is 4%, Pb is 1%, Fe is 2%, Y is 0.5%, Mn is 4%, Ho is 0.01%, The rest is Zn for batching.

[0027] The copper wire is pure copper, and its diameter is 1mm. The weight percentage of the chemical composition of the iron wire: C is 0.05%, Si is 0.2%, Mn is 0.25%, P<0.02%, S<0.025%, and the rest is Fe; the diameter of the iron wire is 1mm.

[0028] The overall length of the copper wire and the iron wire is equivalent, and the volume percentage of the two metal wires is 10% of the material.

[0029] The surface of the copper wire was chrome-plated according to a conventional method to prepare a chrome-plated copper wire, and the thickness of the chrome-plated layer was 50 microns. Nitriding iron wire was prepared by nitriding the surface of the iron wire according to a conventional method, and the thickness of the nitriding layer was 100 microns. Both the nitrided iron wire and the chrome-plated...

Embodiment 2

[0034] Zinc alloy matrix composition by weight percentage: Al is 45%, Sr is 0.5%, Si is 6%, Pb is 3%, Fe is 4%, Y is 1%, Mn is 6%, Ho is 0.03%, The rest is Zn for batching.

[0035] The copper wire is pure copper with a diameter of 2 mm.

[0036] The composition of the iron wire is 0.09% C, 0.3% Si, 0.35% Mn, P<0.02%, S<0.025%, and the rest is Fe; the diameter of the iron wire is 2mm.

[0037] The overall length of the copper wire and the iron wire is equivalent, and the volume percentage of the two metal wires is 35% of the material.

[0038] The surface of the copper wire was chrome-plated according to a conventional method to prepare a chrome-plated copper wire, and the thickness of the chrome-plated layer was 150 microns.

[0039] Nitriding iron wire was prepared by nitriding the surface of the iron wire according to a conventional method, and the thickness of the nitriding layer was 200 microns. Both the nitrided iron wire and the chrome-plated copper wire formed have ...

Embodiment 3

[0043] Zinc alloy matrix composition by weight percentage: Al is 43%, Sr is 0.3%, Si is 5%, Pb is 2%, Fe is 3%, Y is 0.7%, Mn is 5%, Ho is 0.02%, The rest is Zn for batching.

[0044] The copper wire is pure copper with a diameter of 1.5 mm.

[0045] The weight percentage of the chemical composition of the iron wire: C is 0.07%, Si is 0.25%, Mn is 0.3%, P<0.02%, S<0.025%, and the rest is Fe; the diameter of the iron wire is 1.5mm.

[0046] The overall length of the copper wire and the iron wire is equivalent, and the volume percentage of the two metal wires is 25% of the material.

[0047] The surface of the copper wire is chrome-plated to prepare a chrome-plated copper wire, and the thickness of the chrome-plated layer is 80 microns.

[0048]Nitriding iron wire was prepared by nitriding the surface of the iron wire, and the thickness of the nitriding layer was 150 microns. Both the nitrided iron wire and the chrome-plated copper wire formed have the same overall length. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com