Intelligent concrete containing multi-scale conductive materials and preparation method thereof

A conductive material and concrete technology, which is applied in the field of intelligent concrete and its preparation, can solve the problems of high cost of graphene and the decline of concrete mechanical properties, and achieve the effect of improving mechanical strength and fracture toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] An intelligent concrete containing multi-scale conductive materials, consisting of the following components by weight: 450 parts of cement, 1350 parts of sand, 1600 parts of coarse aggregate, 350 parts of water, 14.4 parts of graphene, 14.4 parts of dispersant, carbon black 60 parts, steel fiber 120 parts.

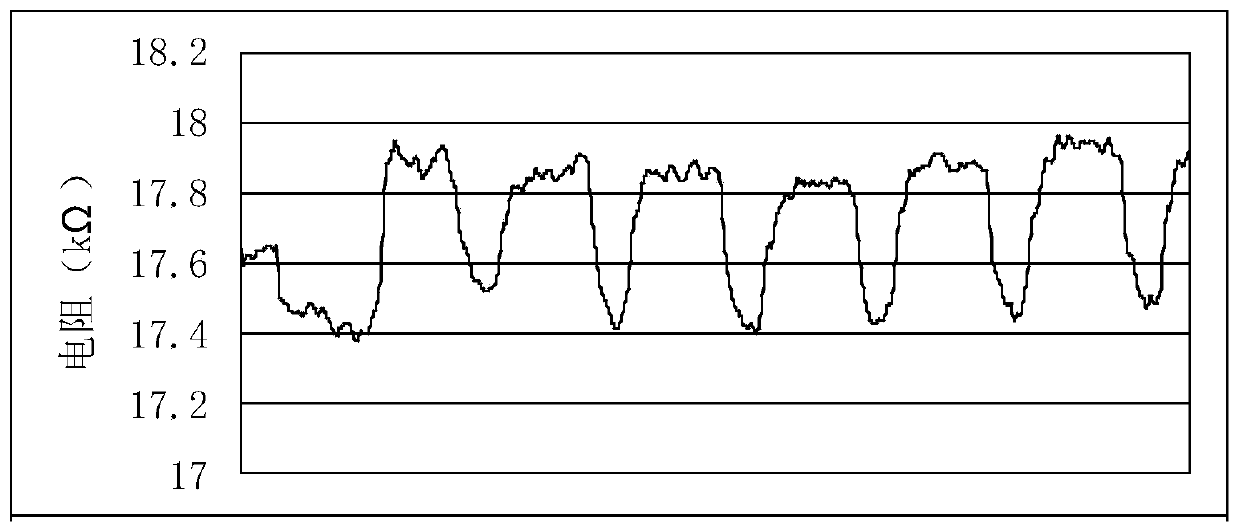

[0028] The compressive strength of the prepared graphene concrete was 35.4MPa, and a cyclic pressure of 1-10MPa was applied to it, and the trend of its resistivity changing with the pressure was measured as follows: figure 1 shown.

Embodiment 2

[0030] An intelligent concrete containing multi-scale conductive materials, consisting of the following components by weight: 300 parts of cement, 1350 parts of sand, 0 parts of coarse aggregate, 270 parts of water, 28.8 parts of graphene, 20 parts of dispersant, carbon black 90 parts, steel fiber 40 parts.

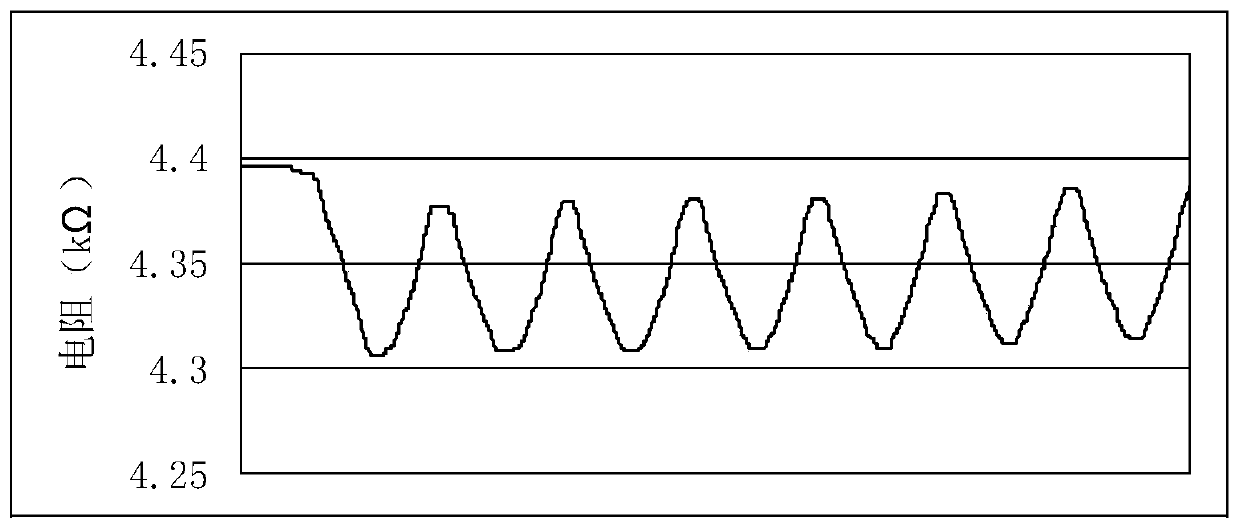

[0031] The graphene concrete compressive strength that makes is 34.9Mpa, and it is applied the cycle pressure of 1-10Mpa, and the trend that its resistivity changes with pressure is measured as follows: figure 2 shown.

Embodiment 3

[0033] An intelligent concrete containing multi-scale conductive materials, consisting of the following components by weight: 450 parts of cement, 600 parts of sand, 1200 parts of coarse aggregate, 300 parts of water, 60 parts of graphene, 30 parts of dispersant, carbon black 60 parts, steel fiber 40 parts.

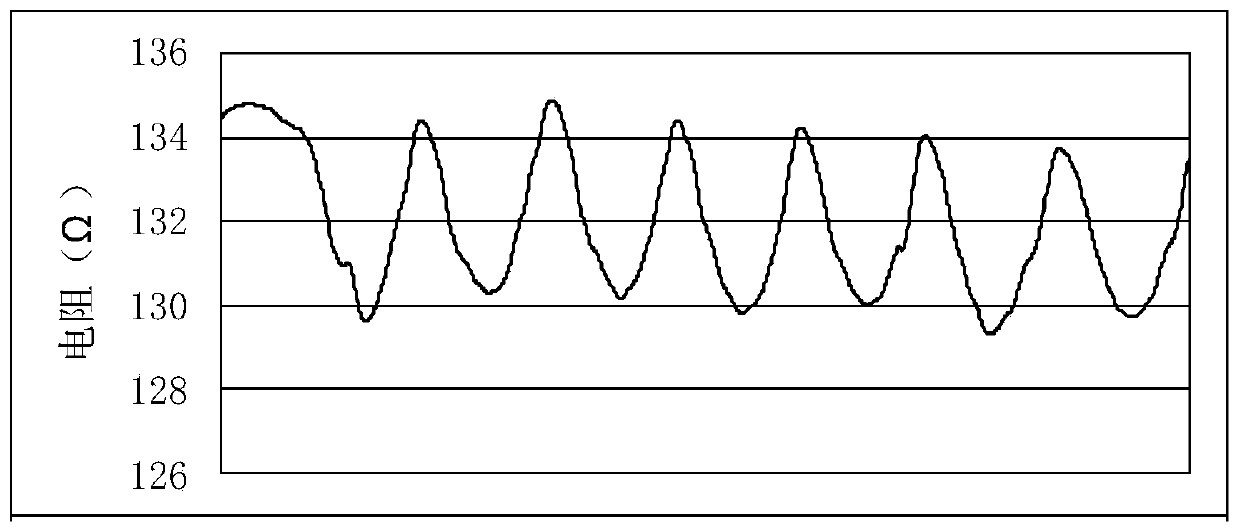

[0034] The graphene concrete compressive strength that makes is 30.4Mpa, and it is applied the cyclic pressure of 1-10Mpa, and the trend that its resistivity changes with pressure is measured as follows: image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com