Preparation method of boron carbide ceramic chips

A technology of boron carbide ceramics and boron carbide, applied in the direction of offensive equipment, protective equipment, armor plate structure, etc., to achieve the effects of enhanced comprehensive anti-ballistic performance, convenient splicing, good dispersion and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Example 1 Preparation of boron carbide ceramic sheet

[0021] Step 1) Raw material powder: select boron carbide powder with an average particle size of 3-5 um as raw material, add 3%-4% graphite powder as a sintering aid, and the average particle size of graphite powder is 1-2 um;

[0022] Step 2) Prepare graphene solution: prepare 1-2 wt% graphene aqueous solution or alcohol solution, add N-methylpyrrolidone as dispersant, and ultrasonically disperse for 10-20 h to obtain a uniformly dispersed solution of graphene; where graphene The sheet diameter>1um, the number of layers <10 layers, the added amount of graphene accounts for 1-5 wt% of the boron carbide powder;

[0023] Step 3) Add the powder obtained in step 1) and the graphene solution obtained in step 2) into a ball mill for 8-10 hours, the speed of the ball mill is 30-50 rpm, and the ratio of ball to material is 2:1;

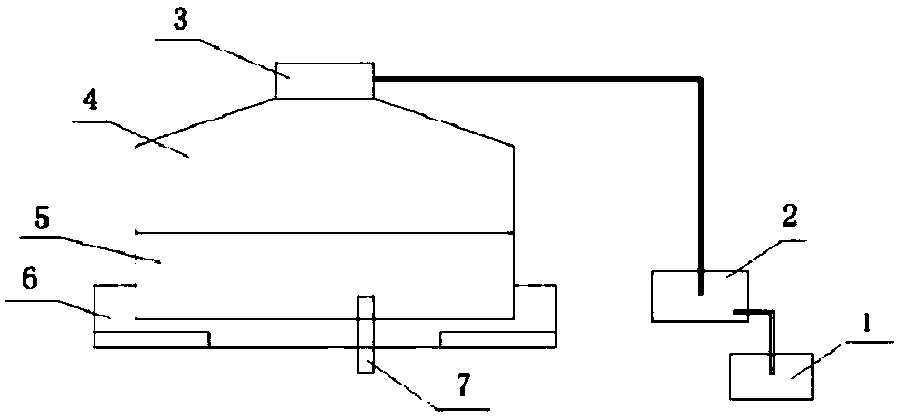

[0024] Step 4) Granulation: such as figure 1 As shown, a granulator is used, which is a granulator made...

Embodiment 2

[0027] Example 2 Boron carbide-titanium alloy composite armor

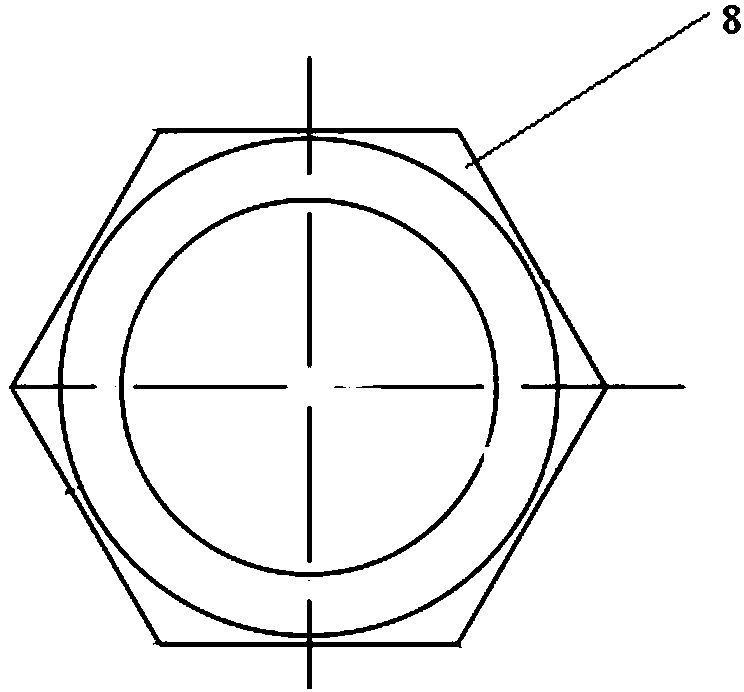

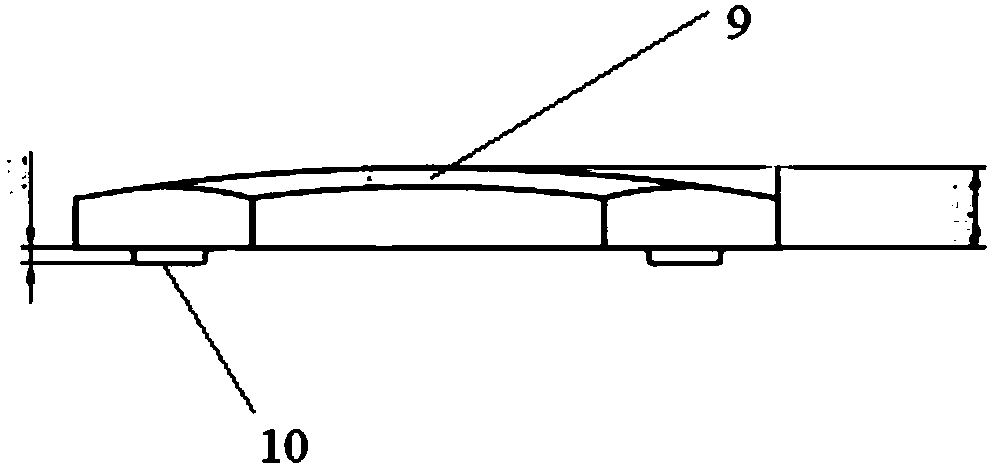

[0028] Step 1) According to the preparation method of embodiment 1, and the graphite mold in step 5) of embodiment 1 is hexagonal, such as figure 2 As shown, a regular hexagonal ceramic sheet is obtained, and the ceramic sheets 8 are spliced together to form a ceramic plate 11.

[0029] Step 2) First, prefabricate a mold with a certain shape according to the size of the boron carbide ceramic plate 11, place the ceramic plate 11 to be poured in the mold, preheat it in an oven at 400°C for 1 hour, and take it out and place it in a casting tank. Then the smelting furnace is heated to a certain temperature. After the titanium alloy is completely melted, it is cast around the ceramic block. After the molten titanium alloy is solidified, the metal-to-ceramic material is encapsulated to form an overall structure of titanium alloy wrapped boron carbide ceramic. The amount of titanium alloy is calculated according to the pou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com