Graphene epoxy compound material for electric automobile driving module and preparation method

A driving module and composite material technology, which is applied in the field of composite materials, can solve the problems that limit the performance and application of graphene/epoxy composite materials, the performance of materials is far from the expected effect, and the dispersion of graphene is uneven, so as to achieve low Stress, high strength, fast curing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

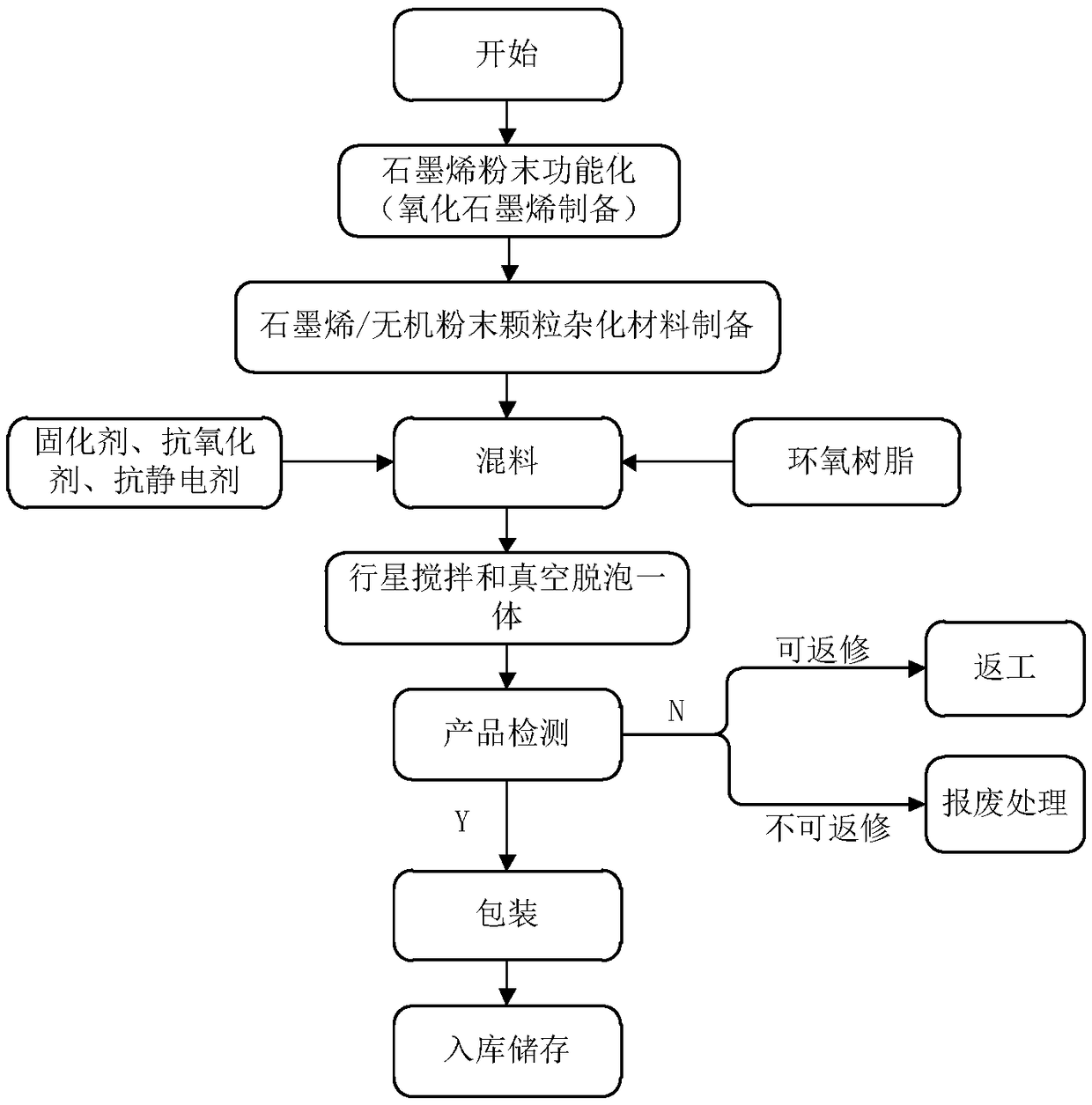

[0048] The graphene-epoxy composite material used in the electric vehicle drive module in this example is composed of graphene / inorganic powder particle hybrid material and epoxy resin, and the graphene / inorganic powder particle hybrid material is uniformly dispersed in the In the matrix of the above epoxy resin. The composite material preparation method of this example is as follows:

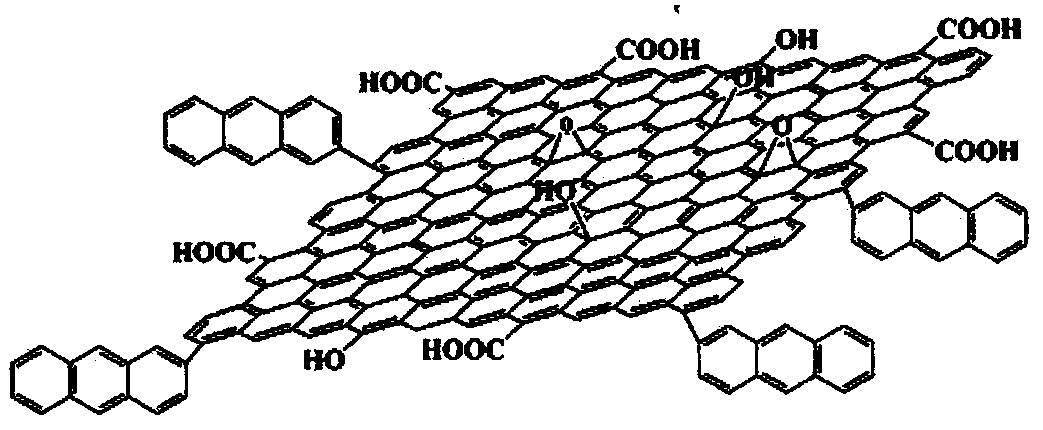

[0049] (1) Graphene oxide surface modification treatment

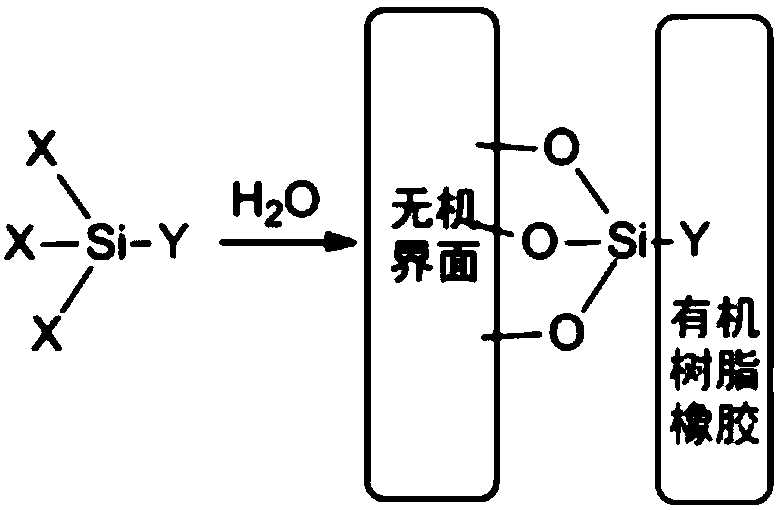

[0050] First, dry the graphene oxide GO powder in a vacuum oven at 100°C for 24 hours; take 2 grams of fully dried GO powder, add it to a 500 mL Schlenk bottle, and add 200 ml of deionized water to make a graphene oxide suspension ; Take by weighing 1% silane coupling agent KH560 of graphene oxide quality and be dissolved in 50ml volume deionized water deionized water, adjust the pH value of this solution to 3.5~5.5, make KH560 solution; Prepare KH560 solution with Graphene oxide suspensions were mixed, hydrolyzed in a water bath at 8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| electron mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com