Silane modified polyether sealant and preparation method thereof

A silane-modified polyether and sealant technology, which is applied in the direction of polyether adhesives, adhesives, carboxyl rubber adhesives, etc., can solve the problems of large proportion of resin, high cost, and difficulty in ensuring long-term performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The preparation steps of described hyperbranched fluorine-containing polyester are as follows:

[0027] Add hyperbranched carboxyl polyester and 2-perfluorooctyl ethanol to the reaction kettle so that the number of moles of carboxyl groups is twice the number of moles of hydroxyl groups, add p-toluenesulfonic acid dropwise under a nitrogen atmosphere, and reflux at 105°C until the acid value of the system is basically Stable, obtain hyperbranched fluorine-containing polyester, viscosity at 25°C <4000mPa.s.

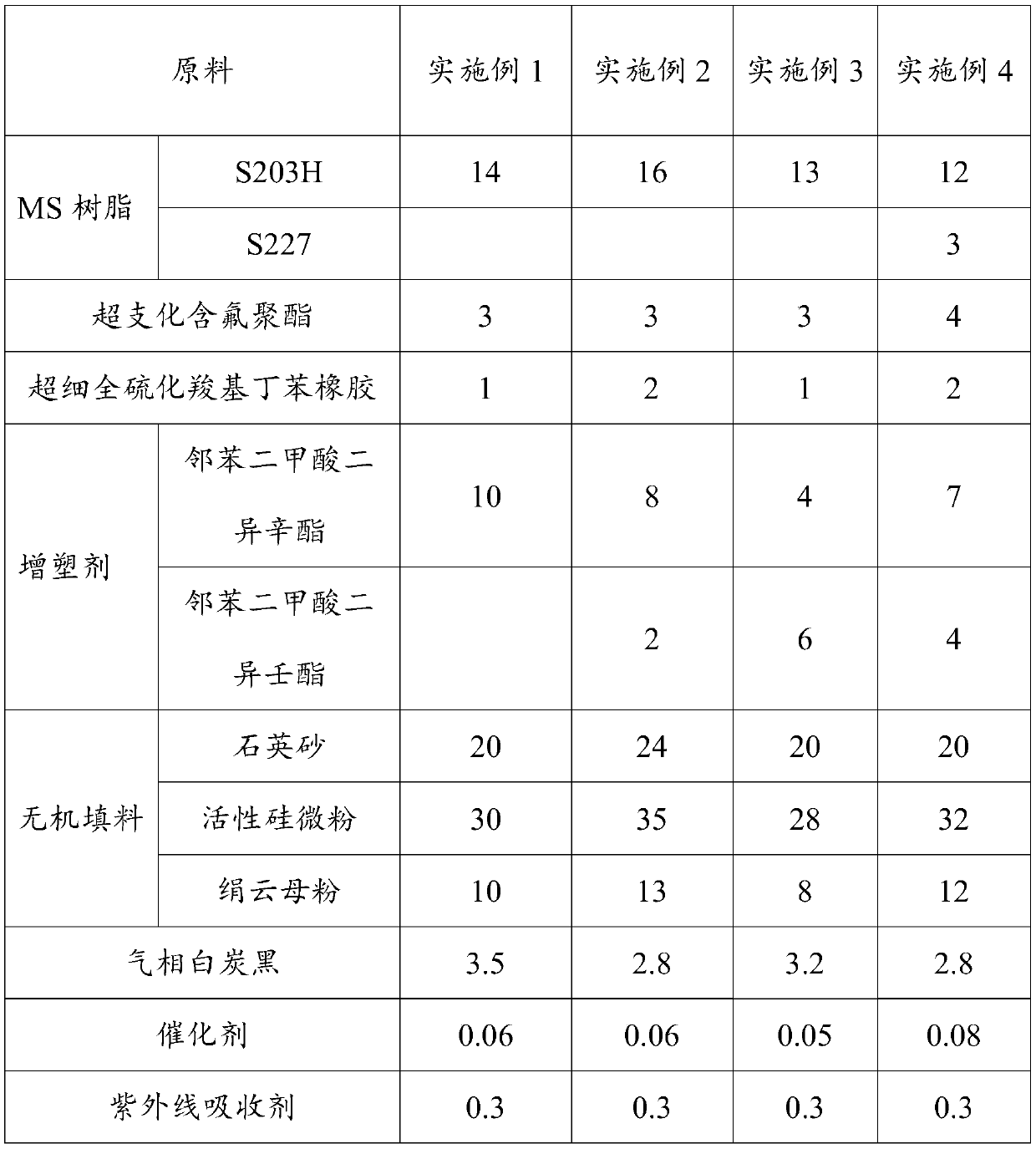

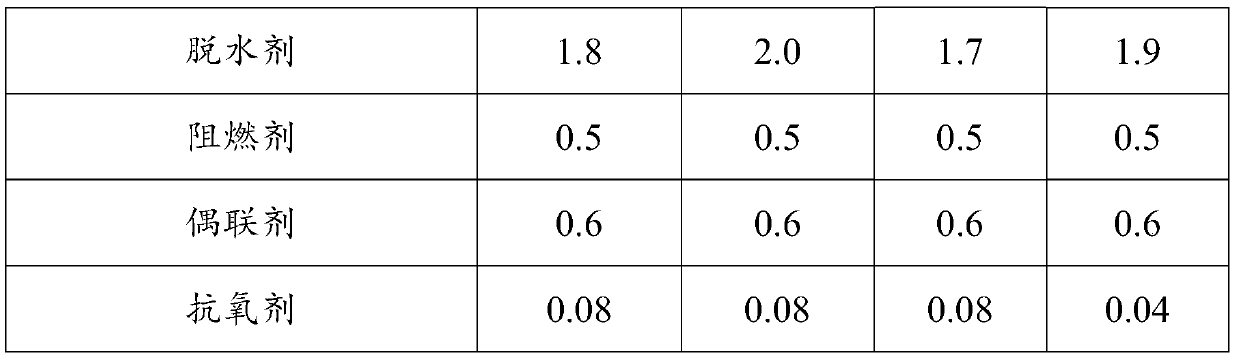

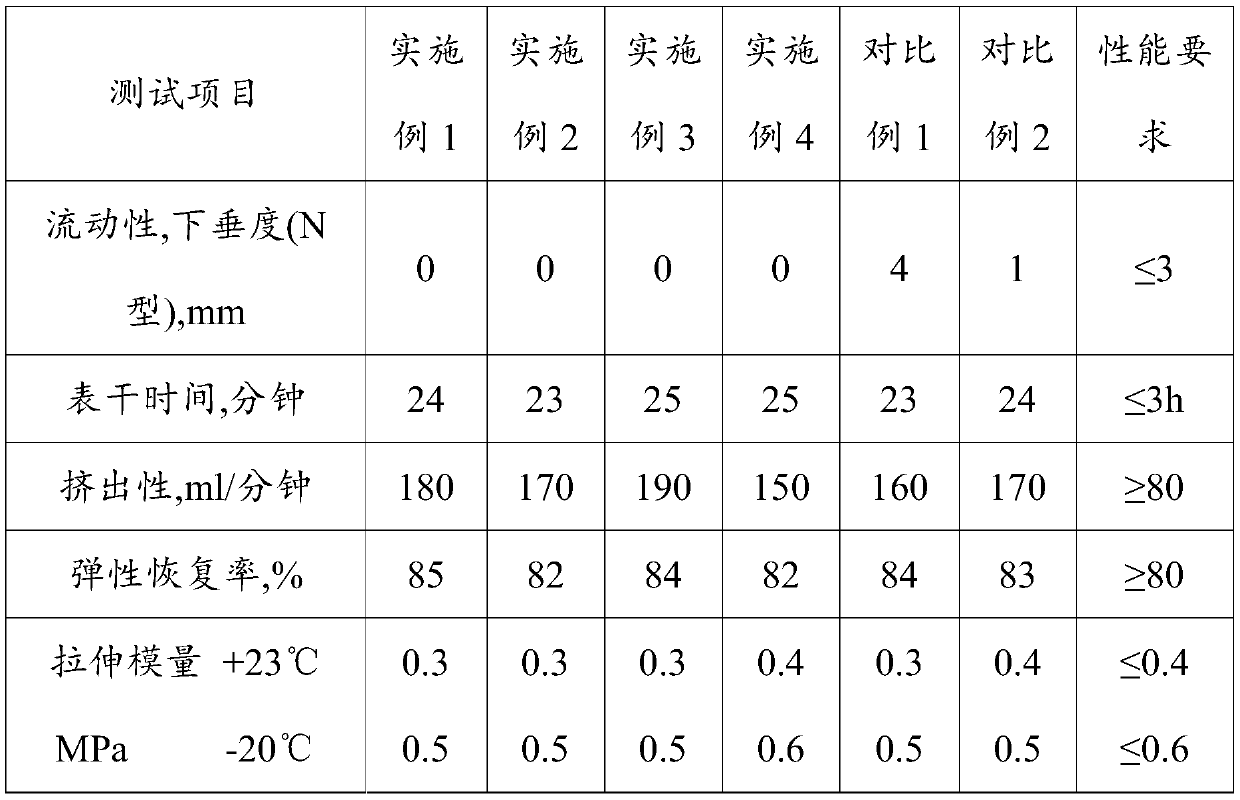

[0028] The sealant formula of embodiments 1 to 4 is shown in Table 1, and the sealant is prepared in the following way:

[0029] (1) Take each component by weight, add hyperbranched fluorine-containing polyester, MS resin, ultrafine fully vulcanized carboxylated styrene-butadiene rubber, plasticizer, and antioxidant into a stainless steel mixing device with a planetary mixer. It has the functions of stirring, temperature adjustment, vacuuming, feeding and dischargi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com