Nano composite coating and preparation method thereof

A nano-composite and coating technology, applied in the field of nano-composite coatings and its preparation, can solve the problems of reducing the construction performance of coatings, ignoring the hydrophobicity and self-cleaning properties of coatings in impact resistance, and achieving improved hydrophobicity, poor suspension stability, Effect of preventing adhesion of dust and dirt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

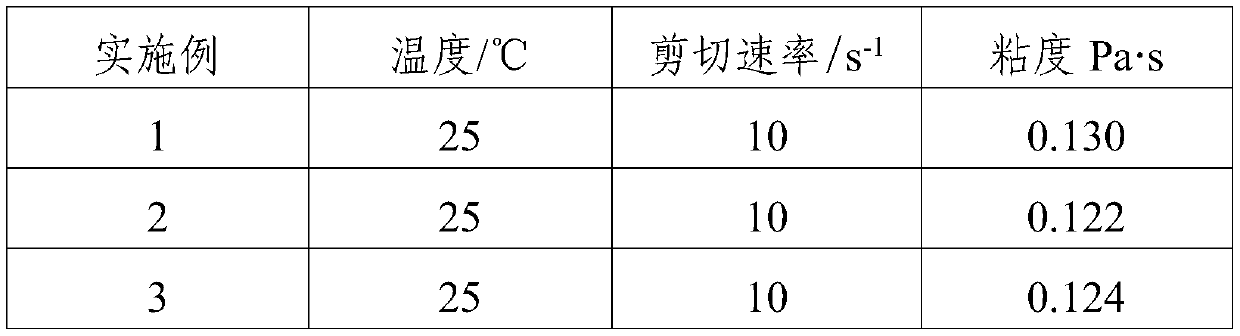

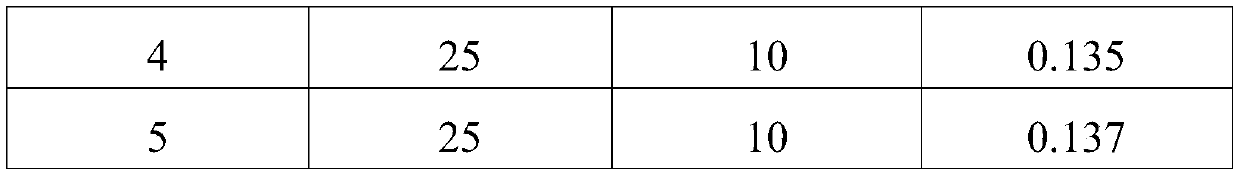

Embodiment 1

[0037] A nanocomposite coating, comprising the following raw materials in parts by weight: 65 parts of star-shaped acrylic resin, 1 part of nano silicon dioxide, 3 parts of nanoparticles, the nanoparticles include alumina, alumina hydrate and titanium dioxide, and alumina, alumina Hydrate and titanium dioxide are mixed at a ratio of 2:1:1, the dispersant is 0.5, the dispersant is Anjeka 6030, and hexamethylenediamine is 1 part; the star-shaped acrylic resin is composed of acrylic monomer, ethyl 2-bromoisovalerate, copper bromide , ligand, stannous octoate and solvent mixed reaction, star-shaped acrylic resin raw material weight parts are as follows: 20 parts of acrylic acid monomer, acrylic monomer comprises ethyl methacrylate and lauryl acrylate, and ethyl methacrylate Mix with lauryl acrylate 2:1, 1.5 parts of ethyl 2-bromoisovalerate, 0.5 parts of copper bromide, 0.5 parts of ligand, 0.5 parts of stannous octoate, 50 parts of solvents, including anisole and toluene, And ani...

Embodiment 2

[0044] A nanocomposite coating, comprising the following raw materials in parts by weight: 70 parts of star-shaped acrylic resin, 1 part of nano silicon dioxide, 3.5 parts of nanoparticles, the nanoparticles include alumina, alumina hydrate and titanium dioxide, and alumina, alumina Hydrate and titanium dioxide are mixed at a ratio of 2:1:1, the dispersant is 0.5, the dispersant is Anjeka 6030, and hexamethylenediamine is 1 part; the star-shaped acrylic resin is composed of acrylic monomer, ethyl 2-bromoisovalerate, copper bromide , ligand, stannous octoate and solvent mixed reaction, each raw material weight part of star-shaped acrylic resin is as follows: 25 parts of acrylic monomers, acrylic monomers include ethyl methacrylate and lauryl acrylate, and ethyl methacrylate Mix with lauryl acrylate 2:1, 1.5 parts of ethyl 2-bromoisovalerate, 0.5 parts of copper bromide, 0.5 parts of ligand, 0.5 parts of stannous octoate, 55 parts of solvents, including anisole and toluene, And ...

Embodiment 3

[0051] A nanocomposite coating, comprising the following raw materials in parts by weight: 75 parts of star-shaped acrylic resin, 1.5 parts of nano silicon dioxide, 4 parts of nanoparticles, the nanoparticles include alumina, alumina hydrate and titanium dioxide, and alumina, alumina Hydrate and titanium dioxide are mixed according to 2:1:1, dispersant 1, dispersant is Anjeka 6030, 1 part of hexamethylenediamine; star-shaped acrylic resin is composed of acrylic monomer, ethyl 2-bromoisovalerate, copper bromide , ligand, stannous octoate and solvent mixed reaction, each raw material weight part of star-shaped acrylic resin is as follows: 25 parts of acrylic monomers, acrylic monomers include ethyl methacrylate and lauryl acrylate, and ethyl methacrylate Mix with lauryl acrylate 2:1, 1.5 parts of ethyl 2-bromoisovalerate, 1 part of copper bromide, 0.5 parts of ligand, 1 part of stannous octoate, 60 parts of solvent, solvents include anisole and toluene, And anisole and toluene w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com