A kind of preparation method of tannic acid-based star polycarboxylate water reducer

A tannic acid-based star, polycarboxylic acid technology, applied in the field of building materials, can solve the problems of molecular structure, insufficient product variety, single molecular structure, complex preparation process, etc., to achieve novel structure, rich surface functional groups, The effect of small hydrodynamic volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

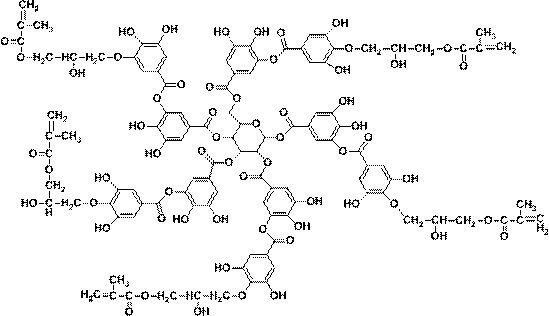

Image

Examples

Embodiment 1

[0016] A preparation method of a tannic acid-based star-shaped polycarboxylate water-reducer, comprising the preparation of modified tannic acid and the synthesis of a tannic-acid-based star-shaped polycarboxylate water-reducer, and the specific steps are as follows:

[0017] (1) Add 5.48g of sodium hydroxide and 135.0g of deionized water into a three-necked round-bottom flask equipped with a thermometer and an electric stirrer, raise the temperature to 65°C, add 51.0g of tannic acid and stir to dissolve them in the water; then slowly Add 71.0 g of glycidyl methacrylate dropwise, and drop evenly within 3 hours. After the dropwise addition, keep stirring at 65°C for 4 hours. After the reaction, a light brown uniform solution is obtained, which is freeze-dried at low temperature to obtain a modified Tannins.

[0018] (2) Add 250.0g of water, 10.0g of modified tannic acid, and 320.0g of polyether macromonomer HPEG into a 1000mL four-necked round-bottom flask equipped with a therm...

Embodiment 2

[0020] A preparation method of a tannic acid-based star-shaped polycarboxylate water-reducer, comprising the preparation of modified tannic acid and the synthesis of a tannic-acid-based star-shaped polycarboxylate water-reducer, and the specific steps are as follows:

[0021] (1) Add 5.48g of sodium hydroxide and 135.0g of deionized water into a three-necked round-bottom flask equipped with a thermometer and an electric stirrer, raise the temperature to 65°C, add 51.0g of tannic acid and stir to dissolve them in the water; then slowly Add 71.0 g of glycidyl methacrylate dropwise, and drop evenly within 3 hours. After the dropwise addition, keep stirring at 65°C for 4 hours. After the reaction, a light brown uniform solution is obtained, which is freeze-dried at low temperature to obtain a modified Tannins.

[0022] (2) Add 250.0g of water, 15.0g of modified tannic acid, and 320.0g of polyether macromonomer TPEG into a 1000mL four-necked round-bottomed flask equipped with a the...

Embodiment 3

[0024] A preparation method of a tannic acid-based star-shaped polycarboxylate water-reducer, comprising the preparation of modified tannic acid and the synthesis of a tannic-acid-based star-shaped polycarboxylate water-reducer, and the specific steps are as follows:

[0025] (1) Add 5.48g of sodium hydroxide and 135.0g of deionized water into a three-necked round-bottom flask equipped with a thermometer and an electric stirrer, raise the temperature to 65°C, add 51.0g of tannic acid and stir to dissolve them in the water; then slowly Add 71.0 g of glycidyl methacrylate dropwise, and drop evenly within 3 hours. After the dropwise addition, keep stirring at 65°C for 4 hours. After the reaction, a light brown uniform solution is obtained, which is freeze-dried at low temperature to obtain a modified Tannins.

[0026] (2) Add 250g of water, 10g of unsaturated modified tannic acid and 320.0g of polyether macromonomer HPEG into a 1000mL four-necked round bottom flask equipped with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com