Rubber composition and processing method, and conveyor belt and production method using the same

A rubber composition and conveyor belt technology, applied in the rubber field, can solve the problems of poor strength performance of conveyor belts and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

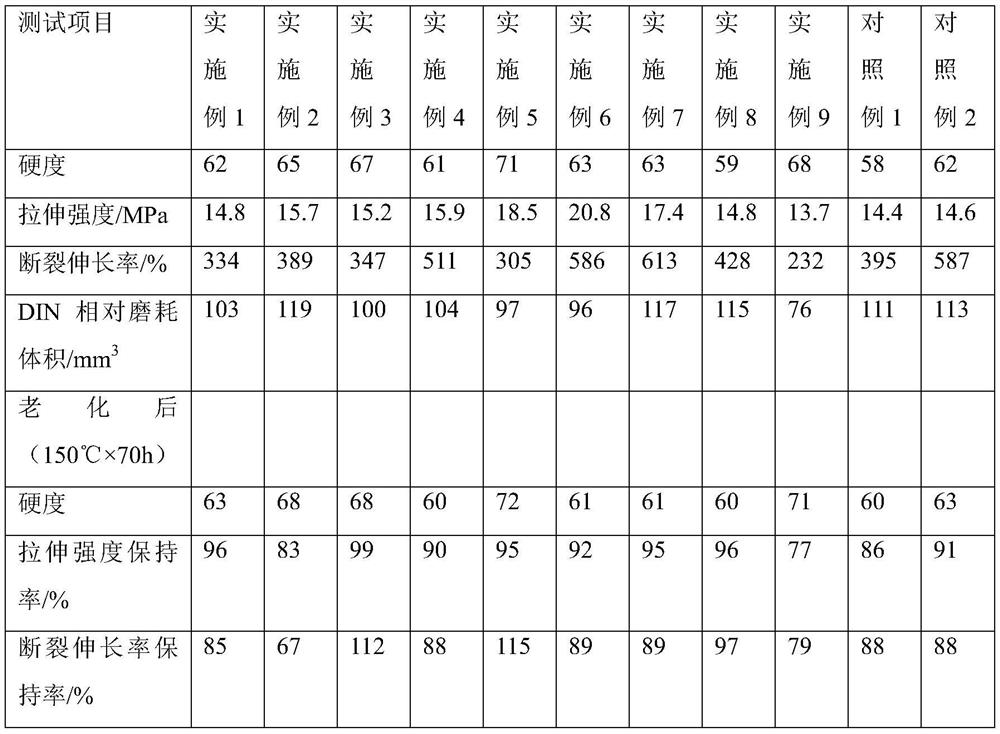

Examples

Embodiment 1

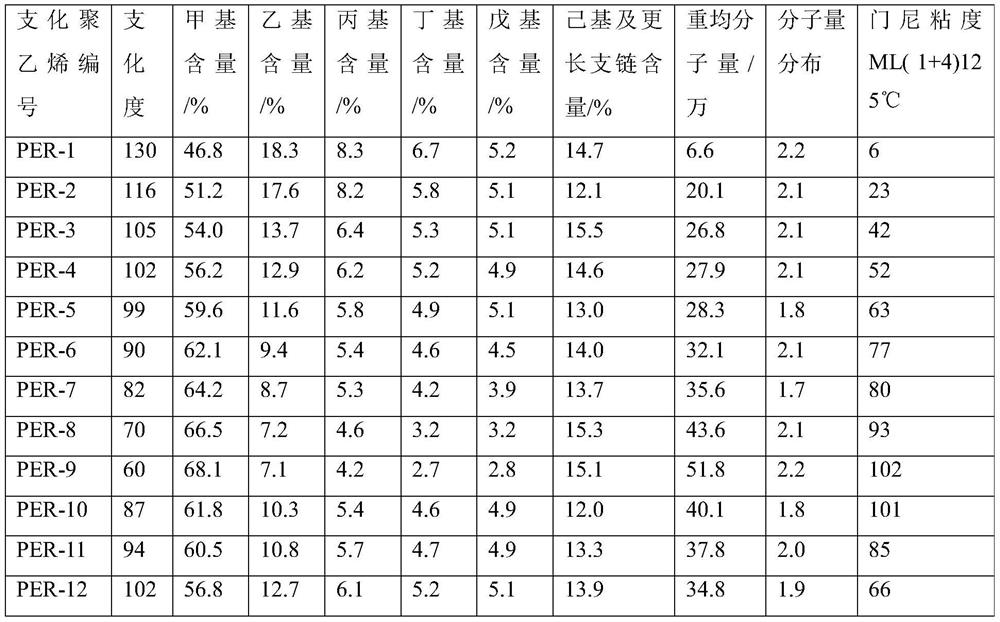

[0098]The branched polyethylene numbered is Per-9.

[0099]The processing steps of the test rubber composition are as follows:

[0100](1) Rubber kneading: Set the intact machine temperature of 100 ° C, the rotor rotation speed is 50 rpm, add 90 parts of three-membered ethylene ethylene rubber and 10 partial branching polyethylene preloading for 90 seconds; 5 parts of oxidation Zinc, 0.2 kinds of stearic acid, 1 anti-aging agent RD, mixed for 1 minute; then add 60 carbon black N330, 25 parts of paraffin oil in the rubber, mixed for 3 minutes; finally add 5 crosslinking agents Oxide oxide (DCP), 1 part guaranteed tri-propyl isocyanurate (TAIC), mixed 2 minutes after pulling, the mixture is on the open mill of 60 ° C Thin Tong, get 2.5mm thick thin film, park for 20 hours

[0101](2) After 16 hours after vulcanization, various tests were performed.

Embodiment 2

[0103]The branched polyethylene numbered is Per-8.

[0104]The processing steps of the test rubber composition are as follows:

[0105](1) Rubber kneading: The mesh temperature is 90 ° C, the rotor speed is 50 rpm, and 80 parts of three-membered ethylene ethylene rubber and 20 parts of branching polyethylene prematch mixed 90 seconds; 10 part yet Zinc and 2 stearic acids, mixing for 1 minute; then 80 copper black N330, 25 servile oil Sunpar2280, mixed for 3 minutes; finally add 1 crosslinking agent peroxide dipropate ( DCP), 0.5 part of the crosslinker sulfur, 1.5 servuliosulfur disulfide tetramethyl Qalanm and 1 vulcanization promoter, a vulcanized trimethyl Qalaum, mixed 2 minutes post-plastic glue, mixed rubber Thin is thin on the open mill at 60 ° C to give a sheet of about 2.5 mm thickness, and is parked for 20 hours.

[0106](2) After 16 hours after vulcanization, various tests were performed.

Embodiment 3

[0108]The branched polyethylene numbered is Per-5.

[0109]The processing steps of the test rubber composition are as follows:

[0110](1) Rubber kneading: Set the intact machine temperature of 100 ° C, the rotor speed is 50 rpm, add 20 parts of binary ethylene ethylene ethylene ethylene ethylene ethylene rubber and 30 parts of branch polyethylene preload mix 90 seconds; 15 parts of zinc oxide, 3 parts magnesium oxide, 3 stearic acids, 1 anti-aging agent RD, mix for 1 minute; then add 50 carbon black N330, 10 servile oil Sunpar2280, Mix for 3 minutes; finally add 6 crosslinking agents peroxide (DCP), 2 partial agent tri-propyl isocyanurate (Taic), blending 2 minutes after gum, will The mixture is thin on the opening mill at 60 ° C, resulting in a sheet having a thickness of about 2.5 mm, parked for 20 hours.

[0111](2) After 16 hours after vulcanization, various tests were performed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com