Coarse fiber for concrete and preparation method of coarse fiber

A crude fiber and concrete technology, applied in fiber processing, fiber chemical characteristics, filament/thread forming, etc., can solve problems such as limited anchoring and slip energy dissipation, affecting fiber reinforcement and toughening effect, and increasing the difficulty of forming and processing. , to achieve the effect of convenient and feasible process flow, reducing or inhibiting cracks, and maintaining the shape of special-shaped sections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] After the polypropylene resin is dried to constant weight, it is added to the twin-screw extruder, and the set temperature of each zone is:

[0031] a district

Second District

Third District

Four districts

five districts

District six

150℃

200℃

220℃

225℃

230℃

220℃

220℃

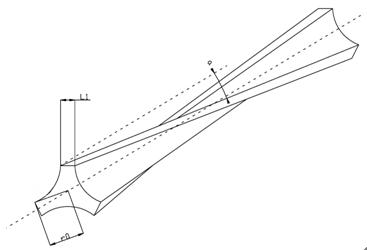

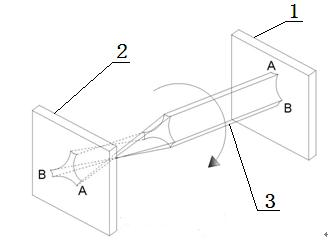

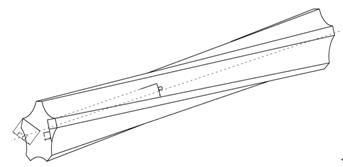

[0032] After melting, it is extruded through the approximately triangular prism-shaped spinneret hole. The concave part between the adjacent edges of the spinneret hole is arc-shaped. into the spinneret hole in the same shape as the spinneret hole but deflected by 45°, the distance between the spinneret hole and the spinneret hole is 40mm, and the filaments passing through the spinneret hole are heated at 85-135°C Two-stage stretching is carried out, and the drafting ratios of each level are 4 times and 1.5 times respectively, and then heat setting is carried out at 110° C., and finally cut into thick fibers wit...

Embodiment 2

[0035] After the polypropylene resin is dried to constant weight, it is added to the twin-screw extruder, and the set temperature of each zone is:

[0036] a district

[0037]After melting, it is extruded through the approximately triangular prism-shaped spinneret hole, and the concave part between the adjacent edges of the spinneret hole is arc-shaped. In the spinneret holes that are in the same shape as the spinneret holes but deflected by 55°, the distance between the spinneret holes and the spinneret holes is 60 mm, and the filaments passing through the spinneret holes are processed at 85-135° Five-stage stretching, the draft ratios of each stage are 3, 2, 1.4, 1.1, and 1.05 times respectively, and then heat-setting at 110°C, and finally cut into thick fibers with a length of 55mm. After testing, the radius r0 of the circumscribed circle of the section is 0.60mm, the edge width L1 is 0.12mm (20% of the radius of the circumscribed circle of the section), the equi...

Embodiment 3

[0039] After the polypropylene resin is dried to constant weight, it is added to the twin-screw extruder, and the set temperature of each zone is:

[0040] a district

[0041] After melting, it is extruded through the spinneret hole with approximately regular pentagonal edges. The concave part between the adjacent edges of the spinneret hole is arc-shaped, and the filament enters the cooling liquid of the bath at 5 ° C. In the spinneret holes that are in the same shape as the spinneret holes but deflected by 35°, the distance between the spinneret holes and the spinneret holes is 45mm, and the filaments passing through the spinneret holes are processed at 85-135℃ Three-stage stretching, the drafting ratios of each stage are 3.8, 2.0, and 1.2 times respectively, and then heat setting is carried out at 110°C, and finally cut into thick fibers with a length of 30mm. The radius r0 of the circumscribed circle of the section is 0.35mm, the edge width L1 is 12% of r0, whic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com