Entire bolt stretcher for nuclear reactor pressure vessels and operating process thereof

A technology for pressure vessels and nuclear reactors, used in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems of complex operation and long operation time, and achieve the effect of increasing safety guarantee and reducing operation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0082] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings.

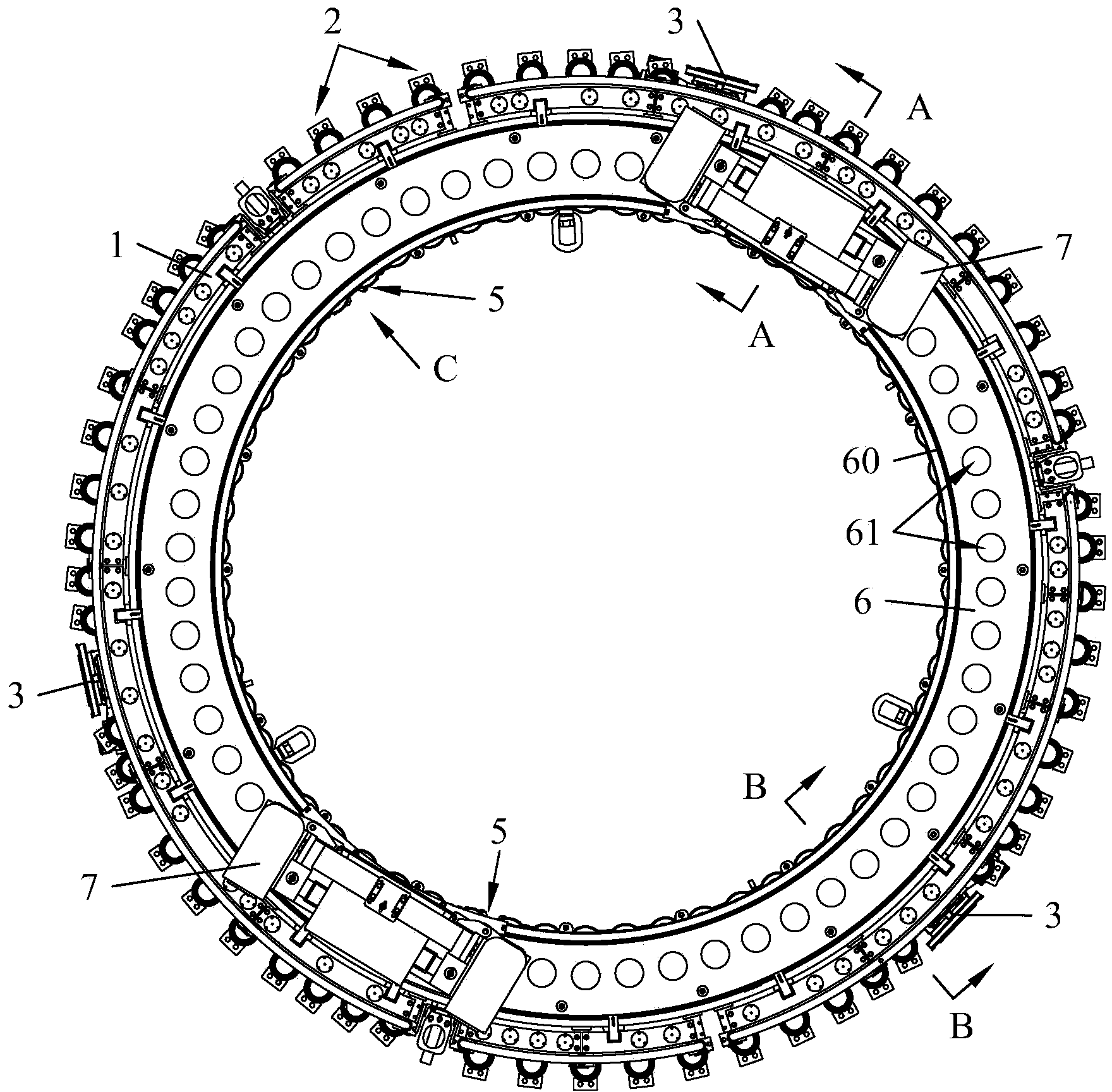

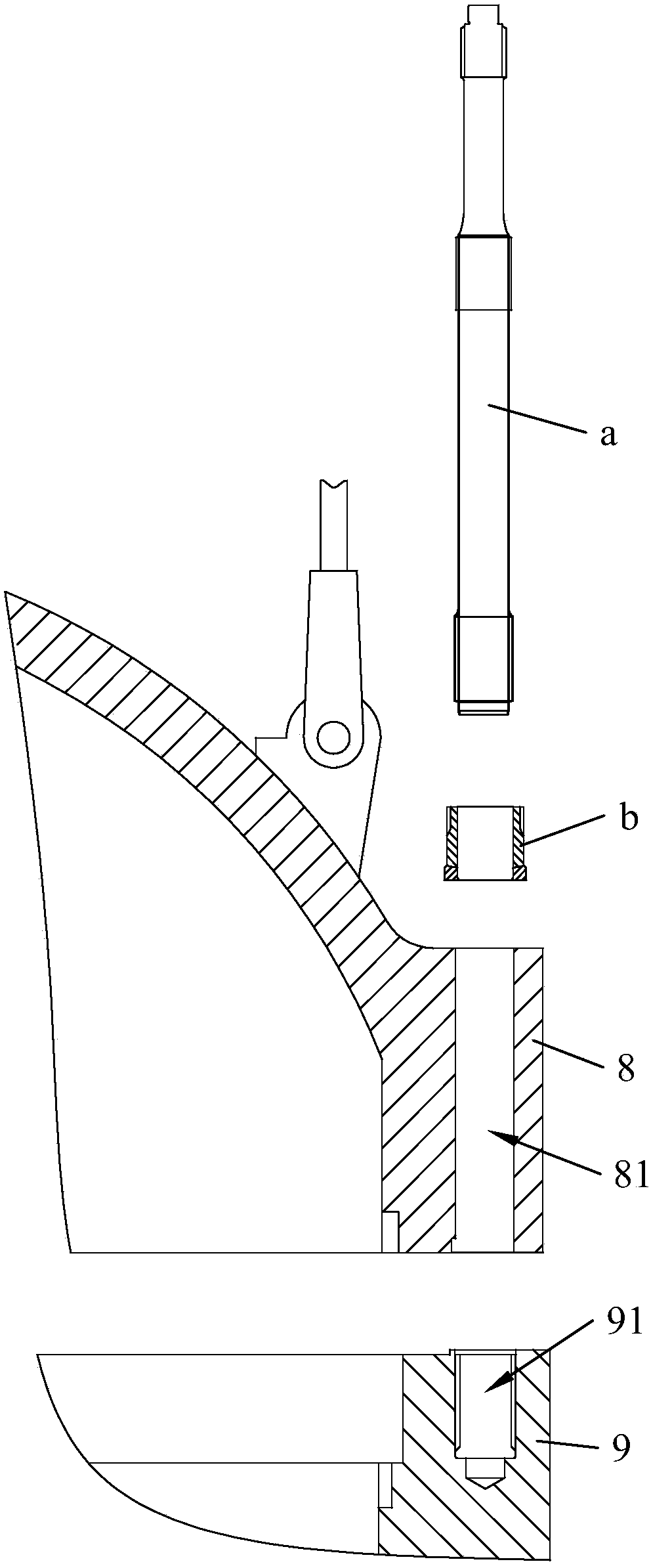

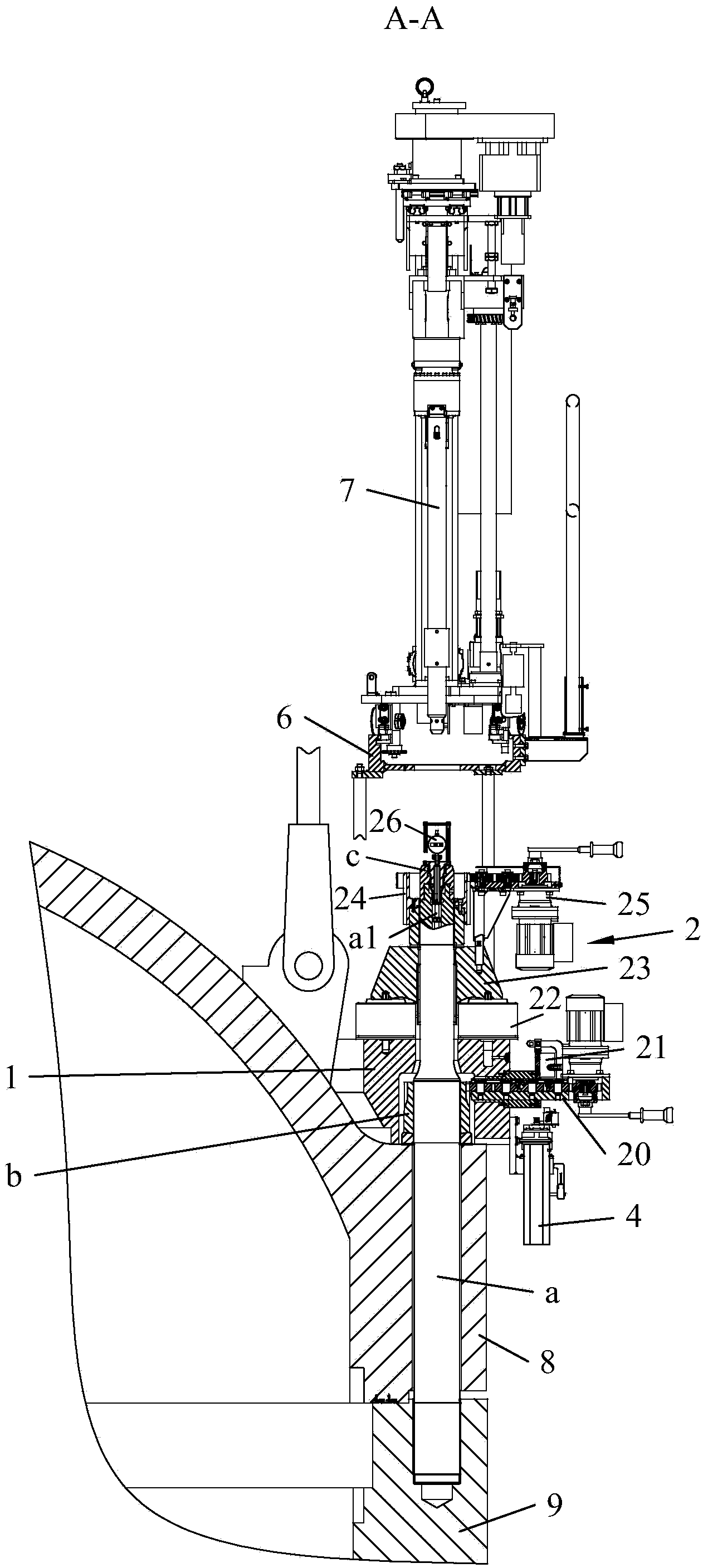

[0083] Such as figure 2 As shown, the integral bolt tensioning machine for nuclear reactor pressure vessel of the present invention can be used to disassemble and assemble the main bolt a on the reactor pressure vessel 9 of the nuclear power plant. A plurality of bolt holes 91, the large reactor cover 8 offers a plurality of through holes 81 corresponding to the plurality of bolt holes 91 one by one, and a plurality of main bolts a are evenly distributed on the outer circumference of the large reactor cover 8 and the pressure vessel 9, and the main bolts a passes through the through hole 81 and is threadedly connected with the bolt hole 91, and a plurality of large cover nuts b which are respectively threaded with the main bolt a are arranged on the large reactor cover 8, and the large cover nut b is tightened on the main bolt a to make the large ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com