Cryogenic vessel multi-performance test device and test method

A low-temperature container and test device technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of large investment, inability to carry out tests on containers, and complicated systems, and achieves improved performance, safe and reliable control and operation. Method and equipment simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

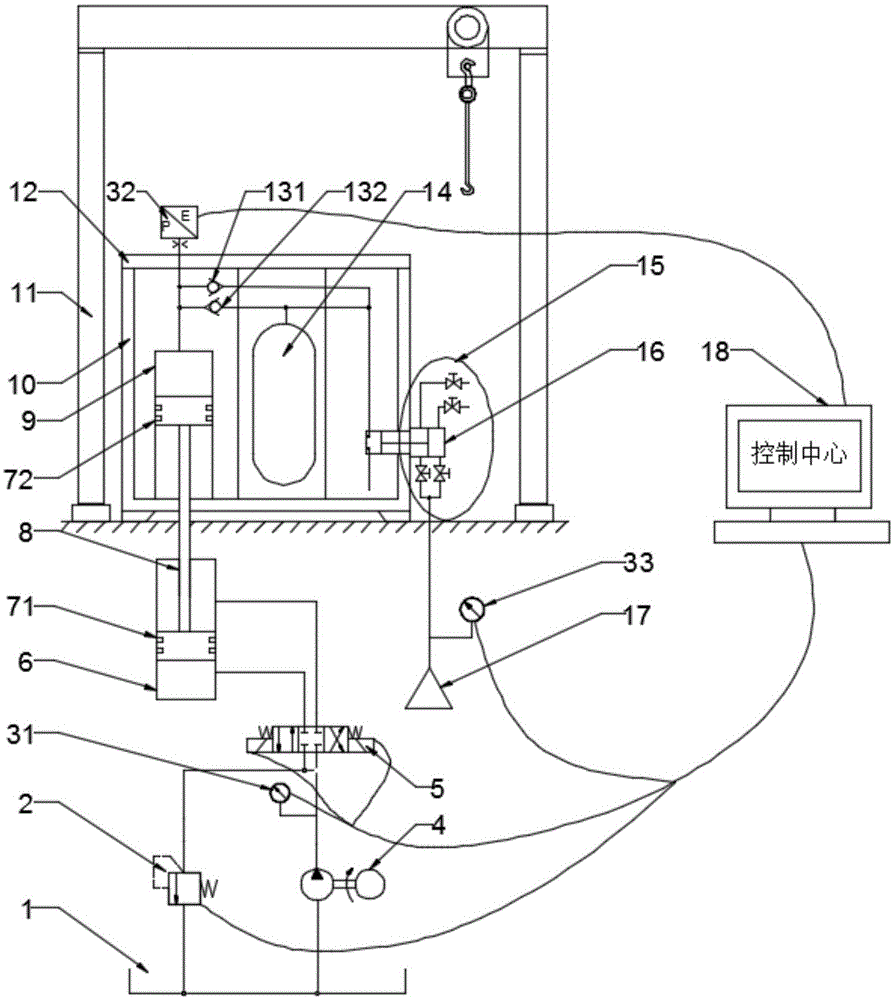

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0028] The cryogenic container multi-performance test device mainly includes a fluid storage 1, a piston accumulator, an insulated box 10, an electromagnetic three-position four-way reversing valve 5, two one-way valves, and a normally open electromagnetic overflow Flow valve 2, a motor pump unit 4, a high-pressure air source 17, an air-driven pump 16, a hoisting device, multiple pressure display and test devices, as well as a device for circulating the fluid during the period, connecting the pressure vessel under test and the fluid The pipeline system of the reservoir is composed, wherein the control center 18 controls the electromagnetic three-position four-way reversing valve 5 and the electromagnetic overflow valve 2 according to the measured pressure signal.

[0029] The piston type accumulator is a double-cylinder structure including a hydraulic cylinder and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com