Passive residual heat removal system for high temperature gas cooled reactor

A technology of passive waste heat and high-temperature gas-cooled reactors, which is applied in the fields of reducing greenhouse gases, reactors, and nuclear power generation. It can solve problems such as failures, and achieve the effects of slow accident process, good reliability and safety, and low failure probability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

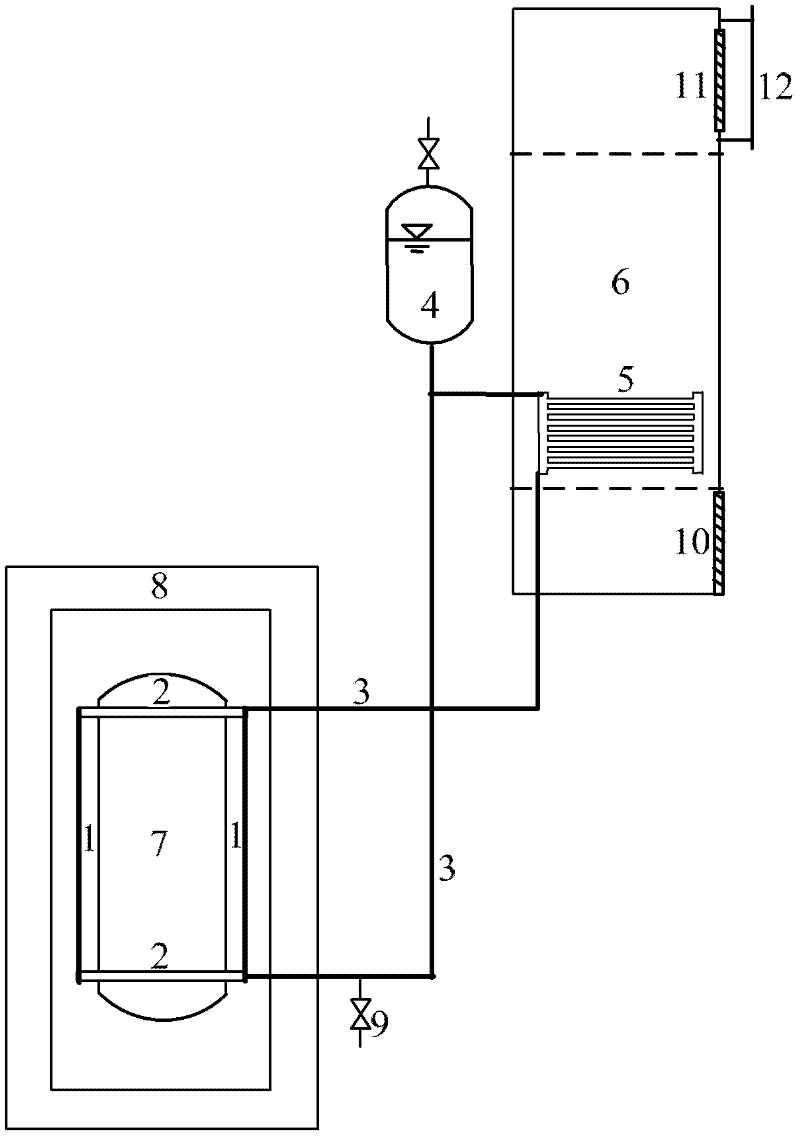

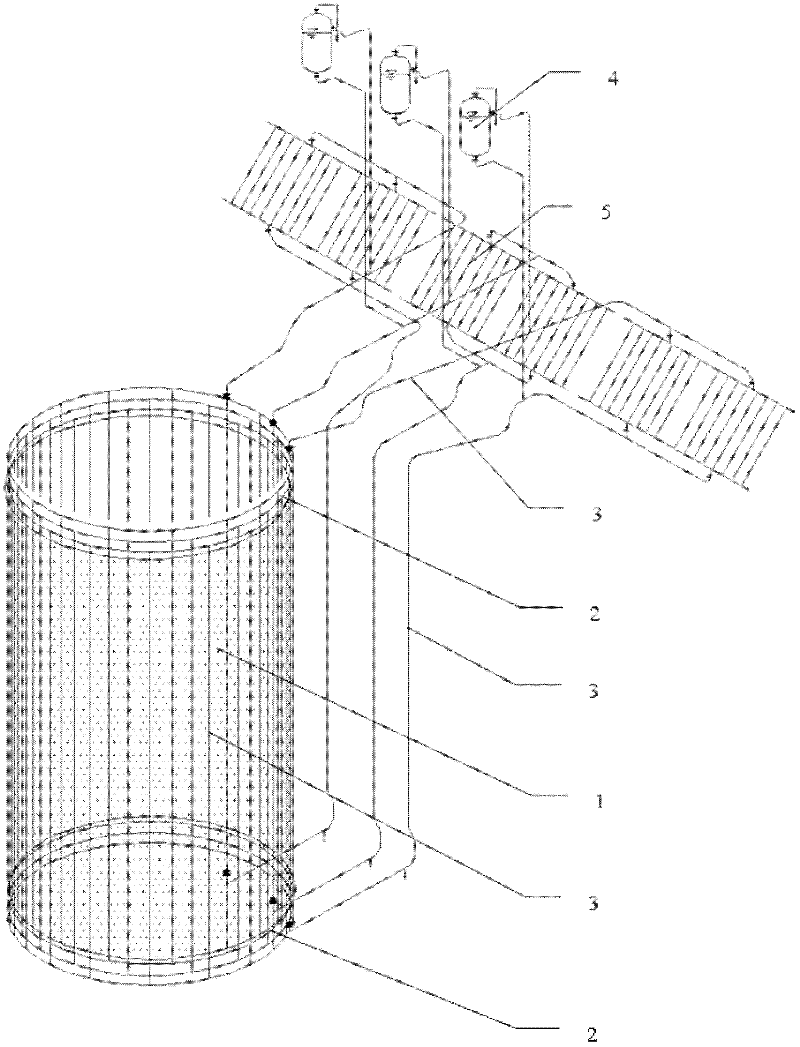

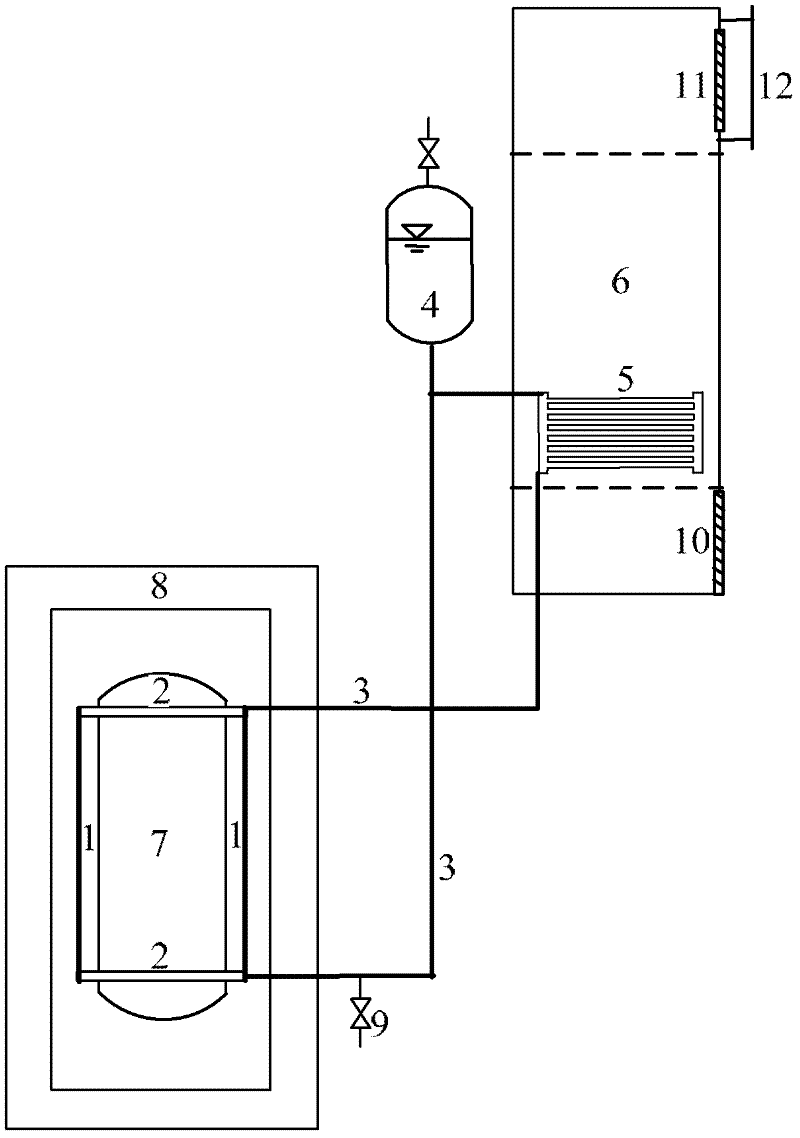

[0027] A high-temperature gas-cooled reactor passive waste heat removal system proposed by the present invention will be described in detail below with reference to the drawings and embodiments.

[0028] The invention provides a high-temperature gas-cooled reactor waste heat removal system based on a passive safety design concept. The operation of the system does not require the action of any active parts and electric valves, nor does it need to be started or switched after the reactor is shut down. The trap—atmospheric, has the characteristics of simple structure, convenient installation and maintenance, and low failure rate. It can simultaneously meet the safety requirements of the cabin cooling function of the high temperature gas-cooled reactor during normal operation and the waste heat discharge function after shutdown.

[0029] The present invention can be designed as multiple sets of sequence redundancy to improve security. The structure of each sequence is as follows ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com