Experiment device for measuring heat transfer properties of high-rayleigh number fusion tank

An experimental device, high Rayleigh number technology, applied in the direction of thermal conductivity of materials, etc., can solve the problems of heating wire and temperature measurement point limitation, comparative study, inability to carry out upper cooling boundary conditions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in detail:

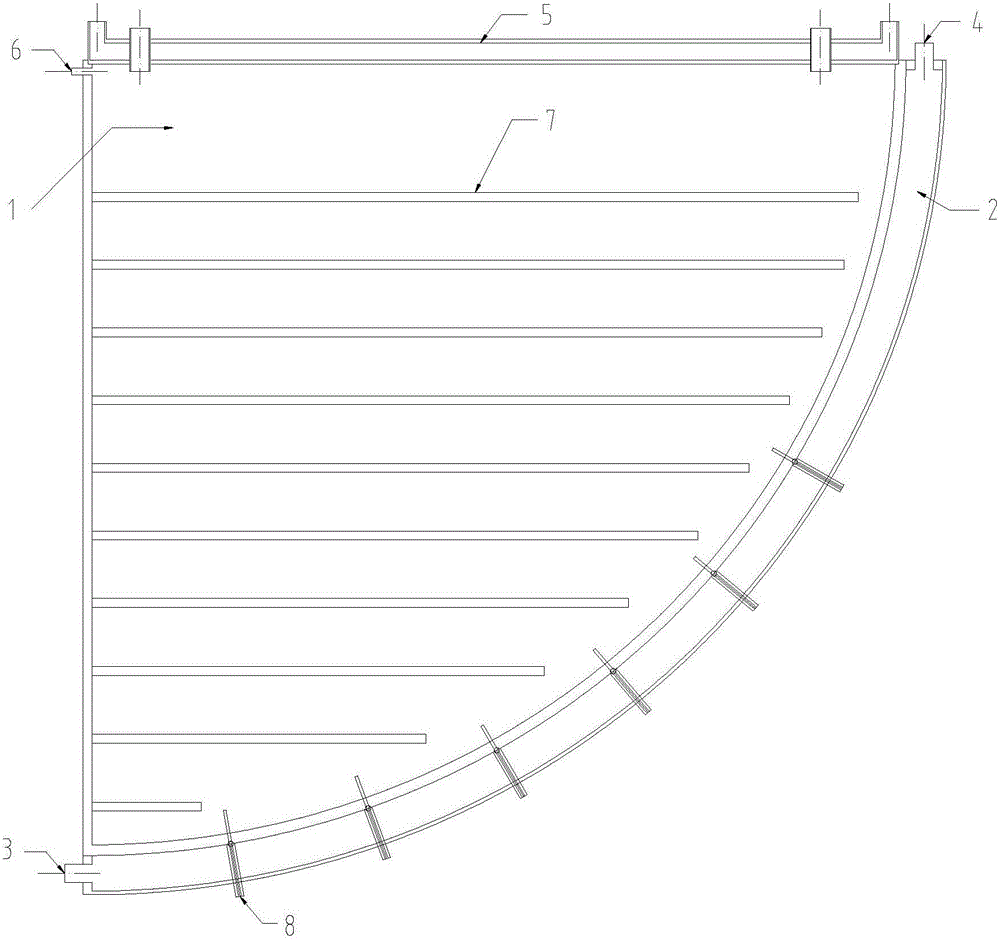

[0038] like figure 1 As shown, the present invention is an experimental device for measuring the heat transfer characteristics of a melting pool with a high Rayleigh number, which is based on a 1 / 4 circle two-dimensional slice structure with a 1:1 ratio of the lower head of the ACP1000 reactor pressure vessel, including the lower head of the melting pool 1, the outer Arc surface cooling channel 2, cooling water inlet joint 3 and cooling water outlet joint 4, upper cover plate 5, nitrogen inlet 6, and corresponding electric heating assembly 7 and temperature measuring assembly 8.

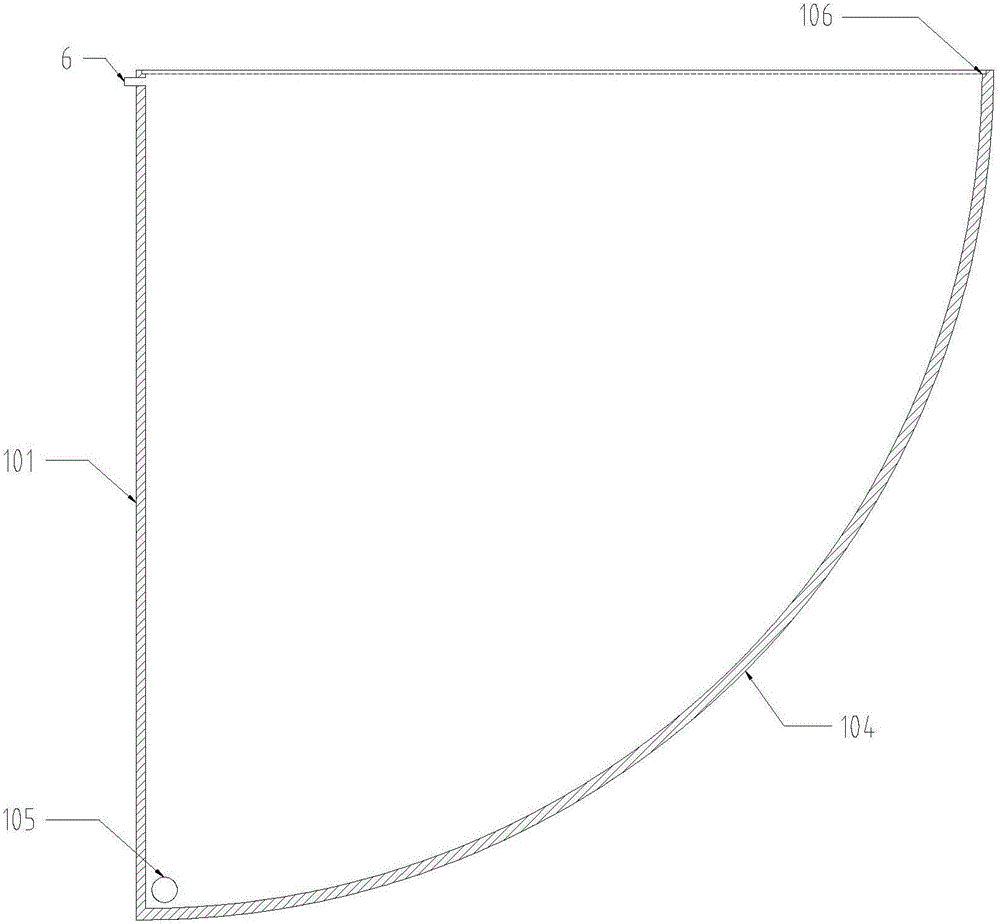

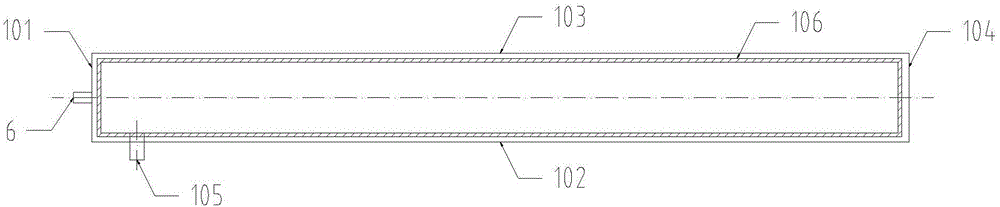

[0039] like Figure 2a and 2b As shown, as a preferred embodiment of the present invention, the molten pool lower head 1 is used to simulate the reactor pressure vessel lower head structure, including a left side wall 101, a front side wall 102, a rear side wall 103, and an ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com