An experimental device for measuring heat transfer characteristics of a three-dimensional ellipsoidal melting pool

An experimental device and melting pool technology, which is applied in the field of experimental devices for measuring the heat transfer characteristics of a three-dimensional ellipsoid molten pool, can solve problems such as small magnitude and insufficient applicability, and achieve the goal of reducing experimental difficulty, facilitating experimental operation, and being easy to process and maintain. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the drawings and specific embodiments:

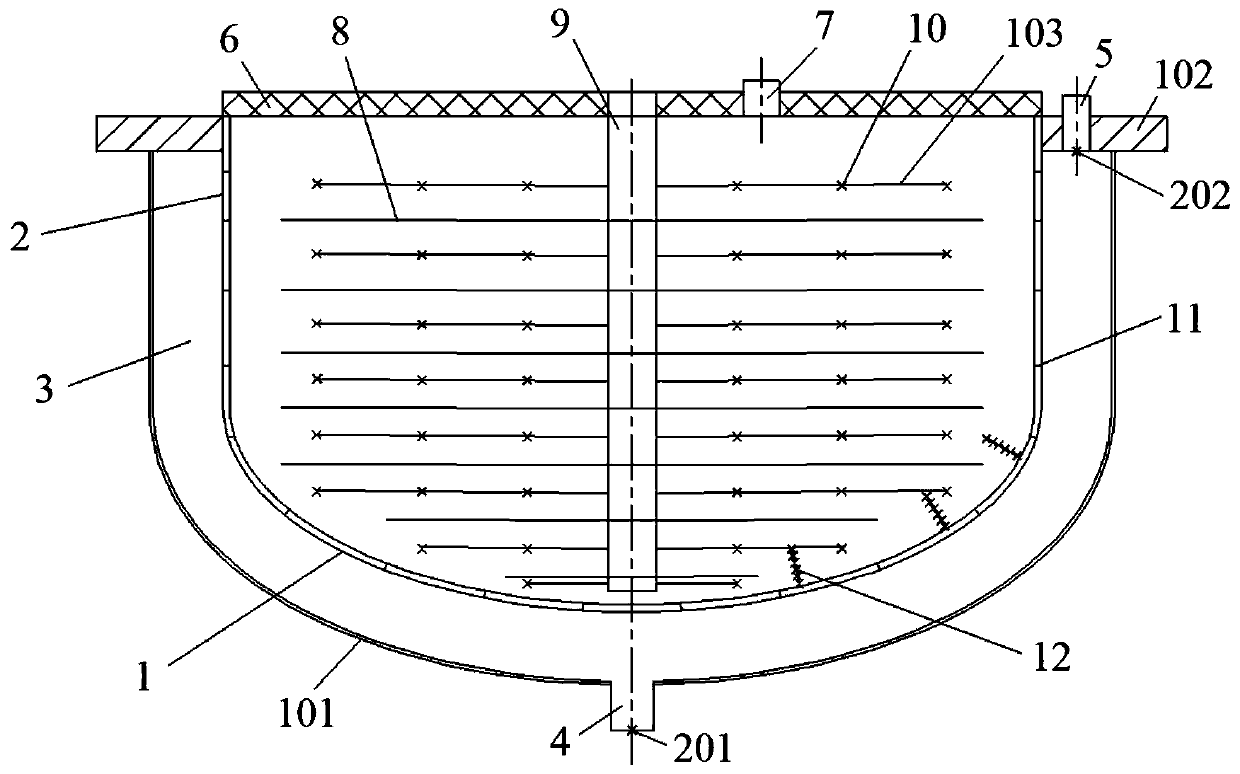

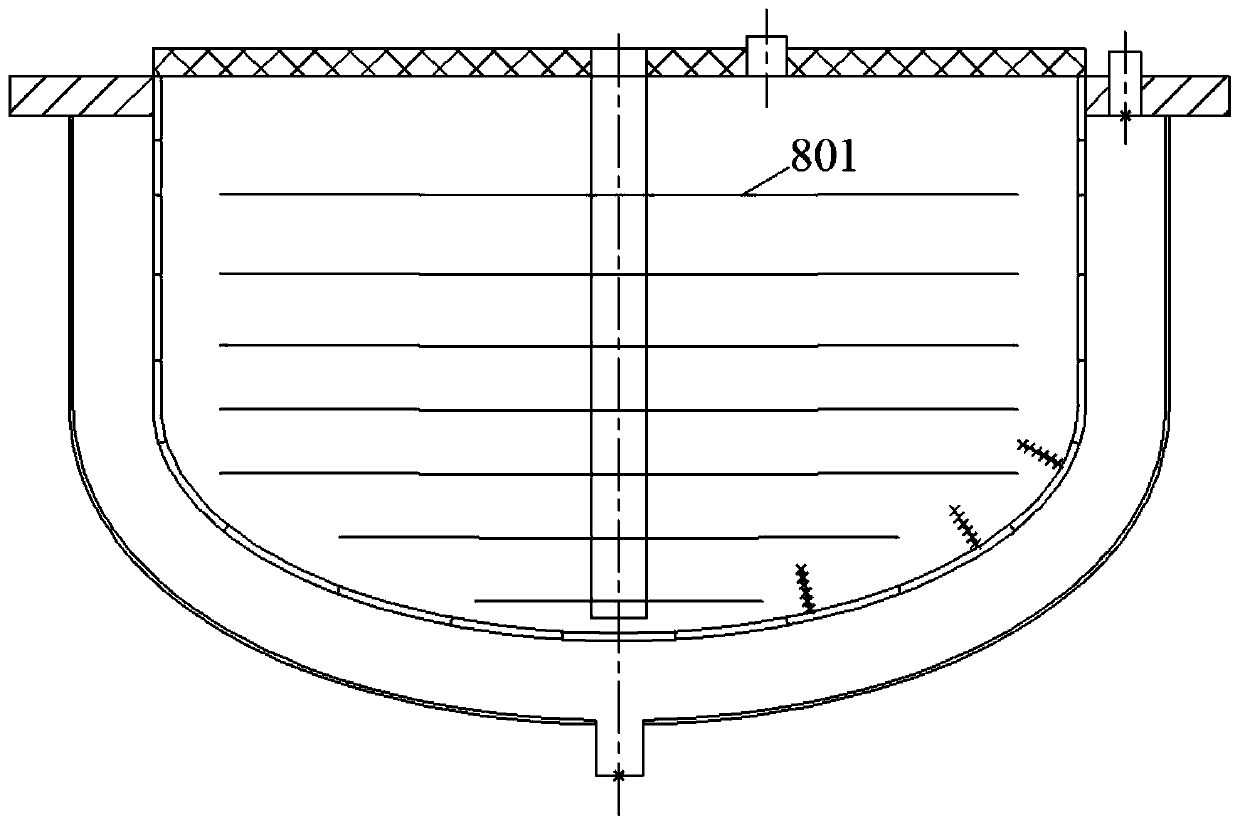

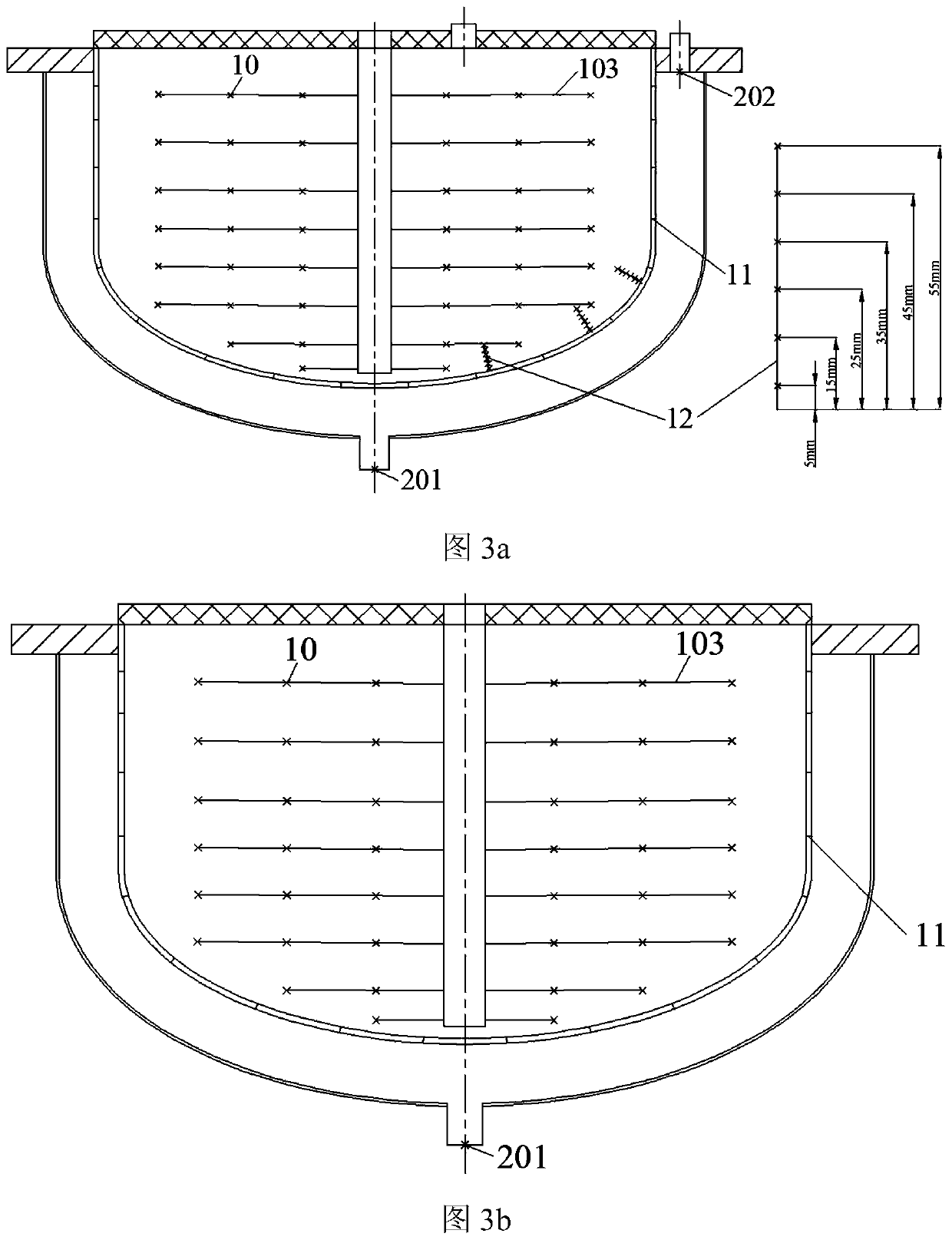

[0025] Such as figure 1 As shown, an experimental device for measuring the heat transfer characteristics of a three-dimensional ellipsoidal molten pool includes an ellipsoidal lower head 1 and an upper cylindrical connecting barrel 2, an external cooling channel 3, a cooling water inlet connection pipe 4, a cooling water outlet connection pipe 5, and an upper portion Cover plate 6, molten salt injection and discharge nozzle 7, volume heating component 8, heating component fixing member 9, temperature measurement thermocouple 10 inside the melting pool, temperature measurement thermocouple 11 on the side wall of the melting pool, and hard shell temperature measurement inside the melting pool. Point thermocouple 12;

[0026] As a preferred embodiment of the present invention, the inner diameter of the experimental device is 1150mm, the depth of the ellipsoidal b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com