Tubular body comprising two or more layers of helically bended strips

A tubular body and tubular technology, which is applied in the field of tubular bodies to achieve the effect of saving material weight and reducing stress corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

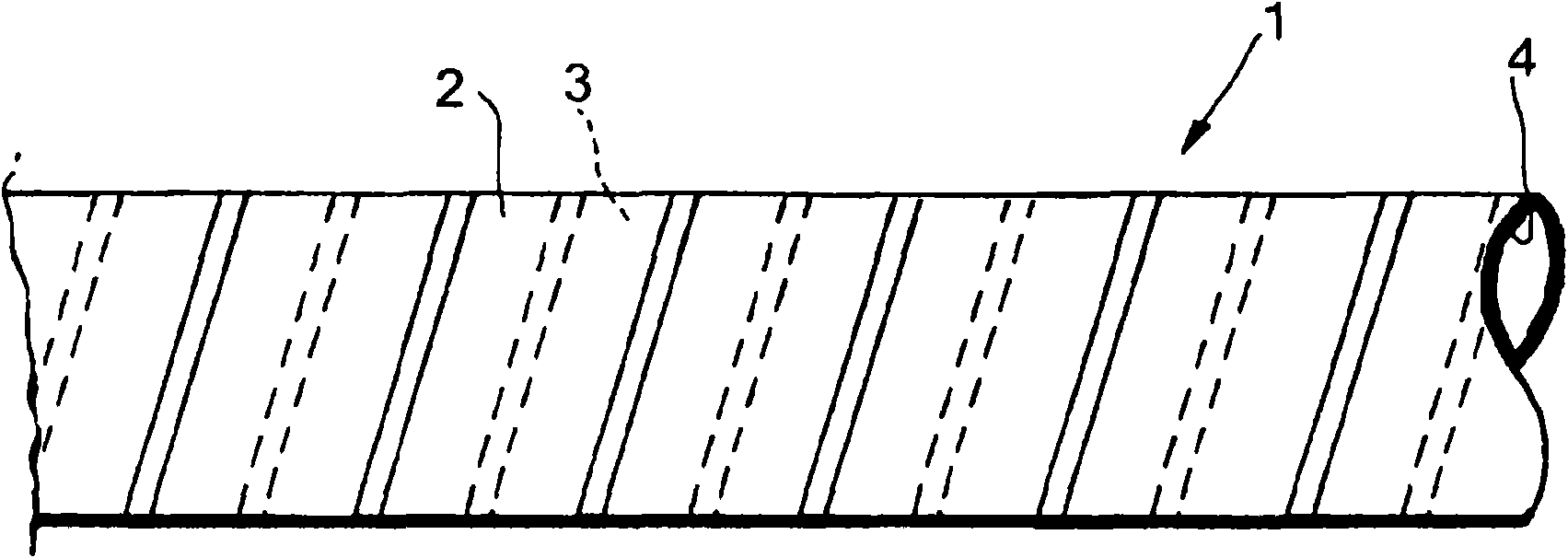

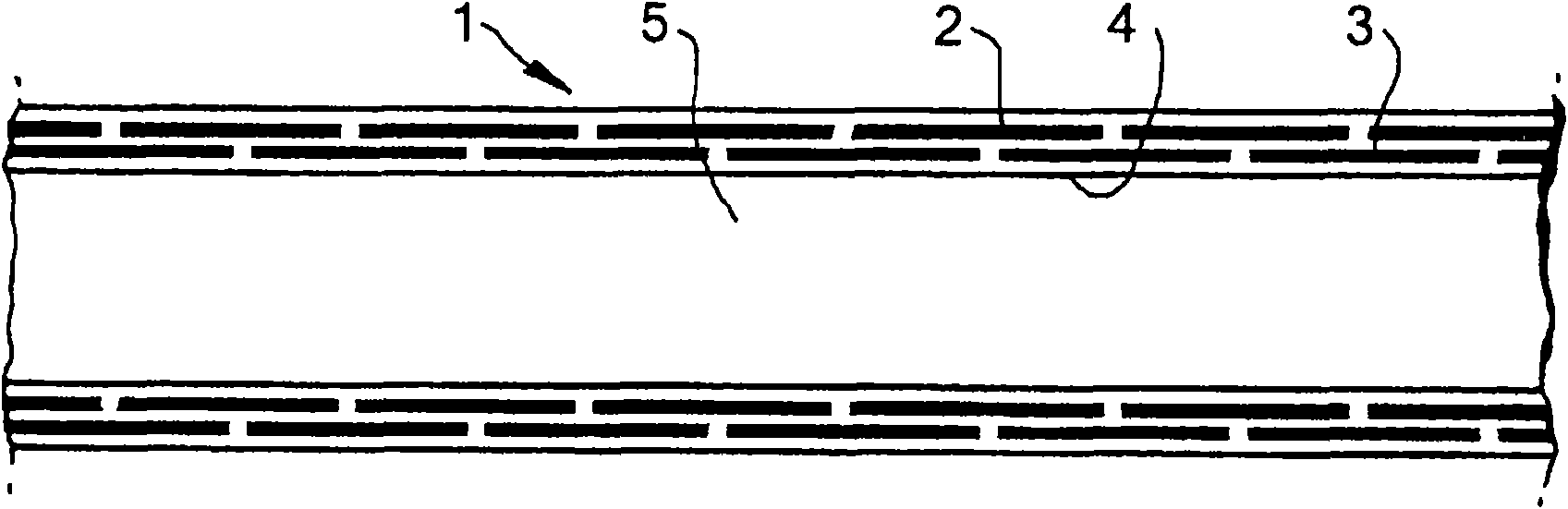

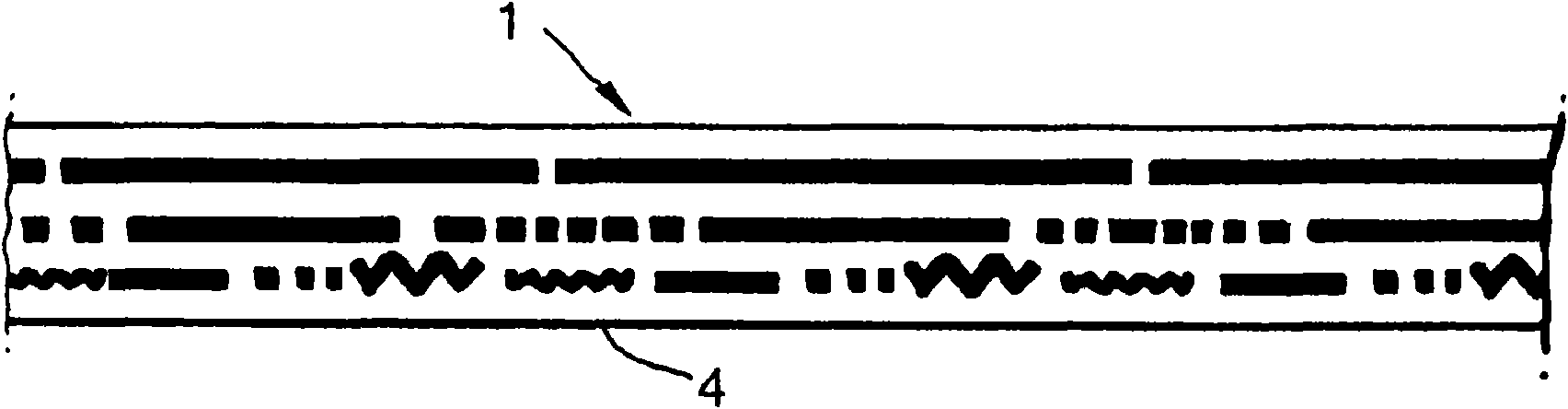

[0039] refer to figure 1 , 2 and 3, show a tubular body 1 comprising two superimposed elongated metal strips 2 and 3 which are helically wound around an inner sleeve 4 which 4 around the hollow core 5. Each layer consists of a metal strip. The overlap between the metal strips in these two layers is 50%. Strips 2 and 3 are made of high strength steel. The strip 3 is wound helically around the inner sleeve 4 . Strip 2 is helically wound around strip 3 in a pattern overlapping by 50%. Between the inner sleeve 4 and the strip 3 and between the strip 3 and the strip 2 there is a thin layer of adhesive. Around the outer metal strip 2 there is a thin layer of protective cladding. Figure 4 An elongated metal strip 3 is shown. In the method according to the invention, the metal strip is helically bent around lines perpendicular to line l (for example l', l" and l"'). It is evident that during the bending process the wire around which the metal strip is bent will move continu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com