High-power loop heat pipe radiator and manufacturing method thereof

A technology of a loop heat pipe and a manufacturing method, which is applied in the direction of indirect heat exchangers, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of affecting the service life of liquid cooling heat dissipation devices, increasing the complexity of mechanisms, and limited heat dissipation capacity, etc., to achieve Meet heat dissipation and installation requirements, save processing time and cost, simple and reliable manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

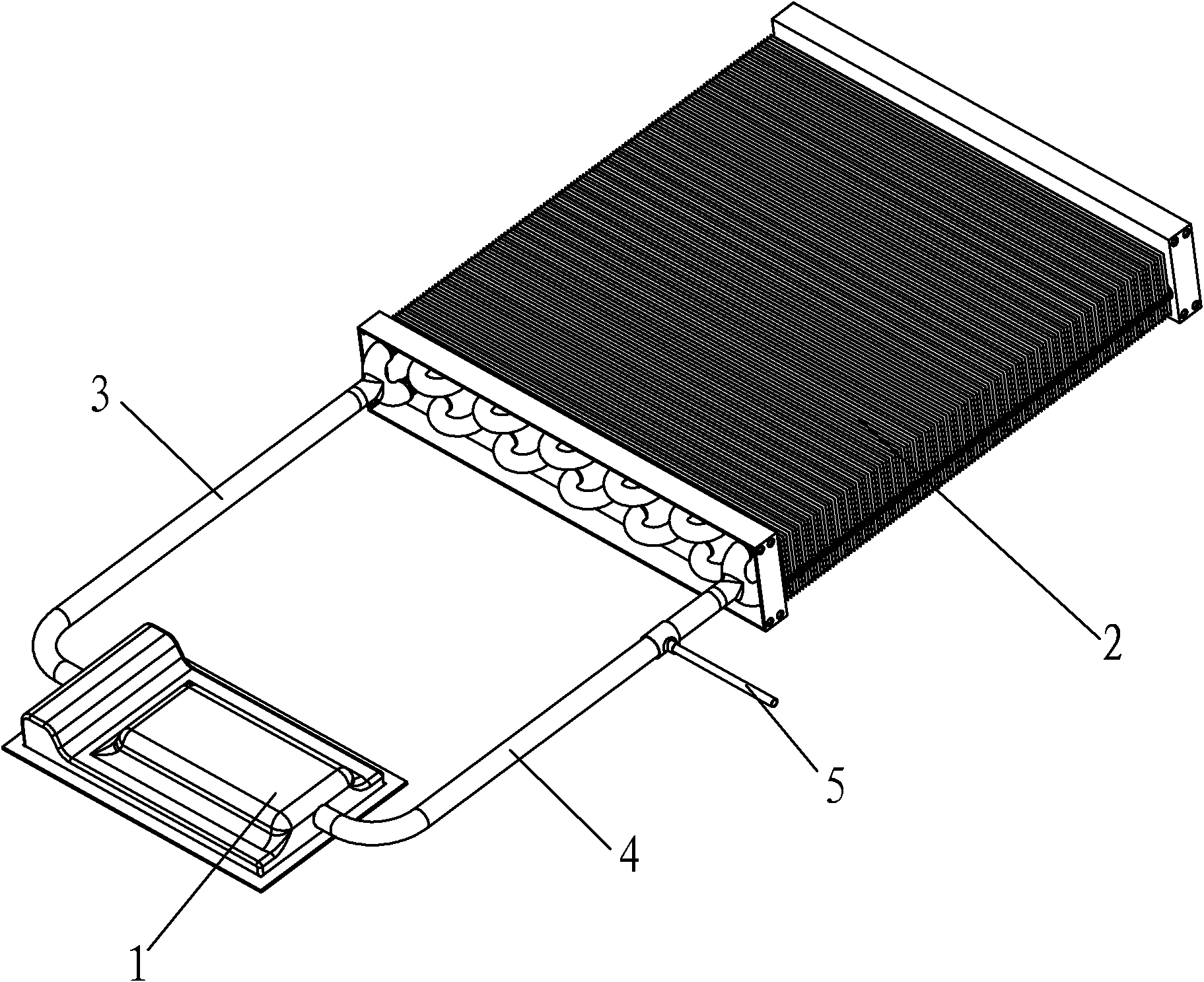

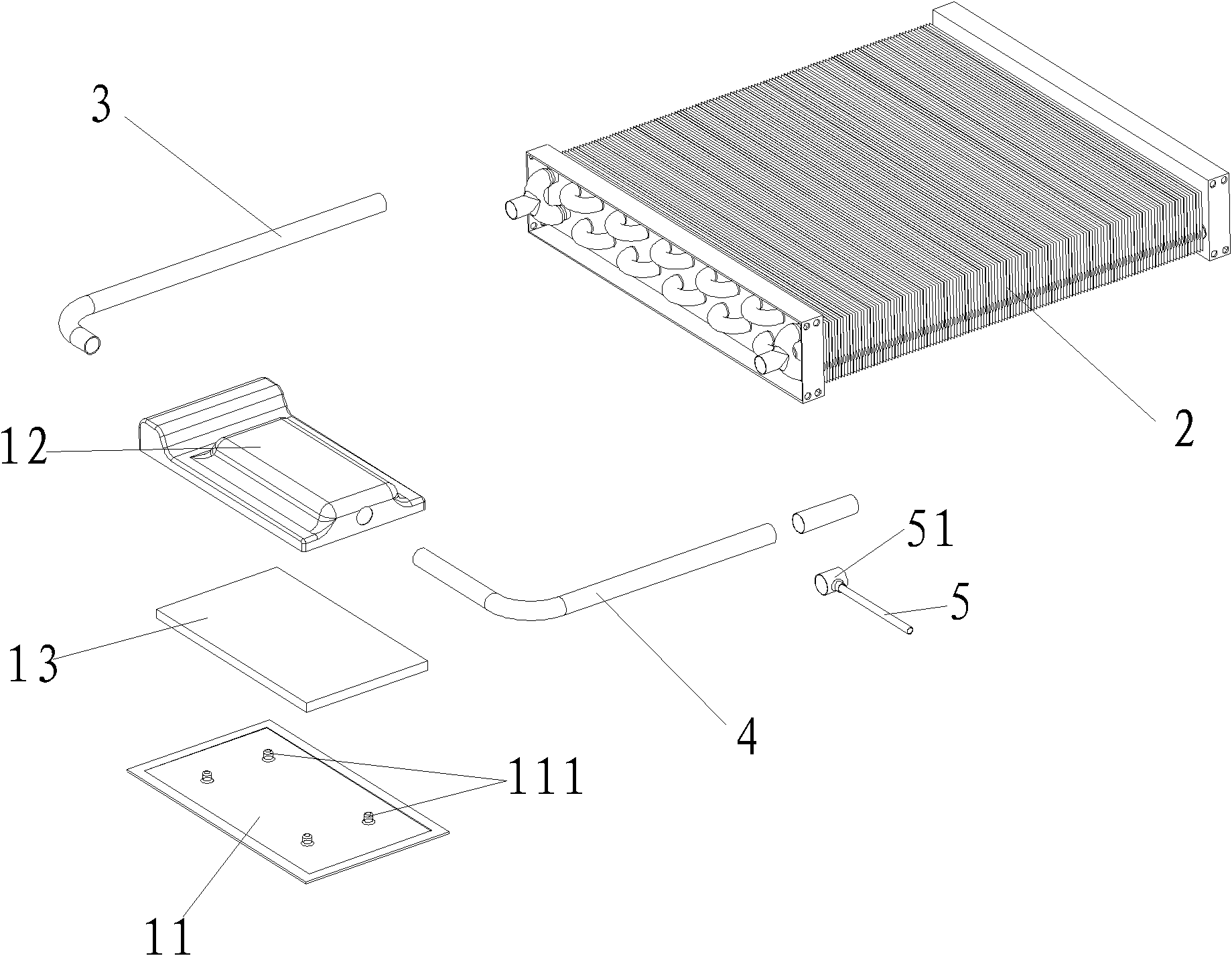

[0036] see figure 1 , figure 2 As shown, a high-power loop heat pipe radiator of the present invention mainly includes an evaporator 1, a condenser 2, and more than one steam pipeline 3 and a liquid pipeline 4 connecting the evaporator 1 and the condenser 2, and the liquid pipeline 4 It is also communicated with vacuumizing and working medium filling pipeline 5.

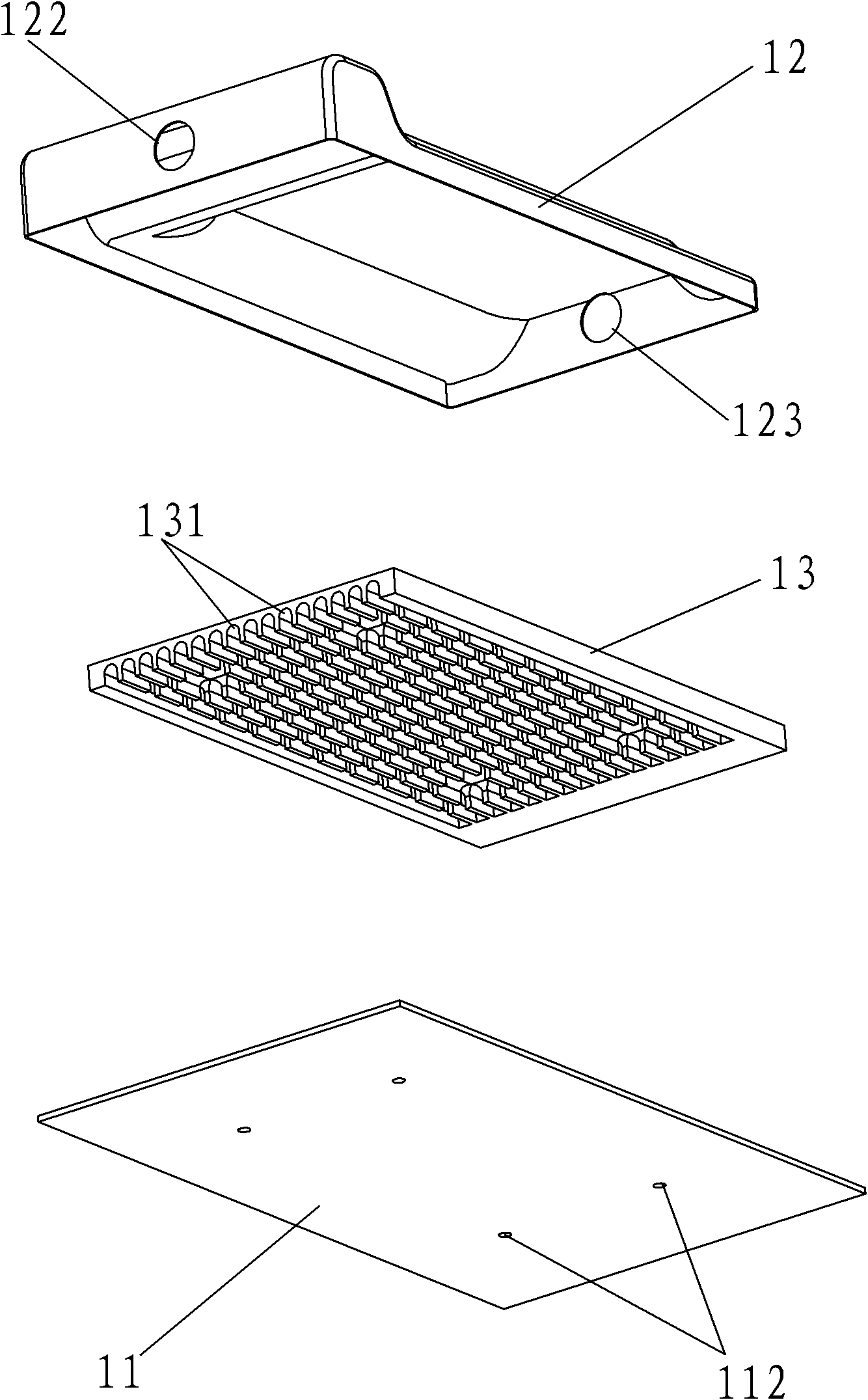

[0037] Among them, please refer to image 3 As shown, the evaporator 1 is a flat plate evaporator, which can be a nearly rectangular parallelepiped or a cube in shape, including a bottom plate 11 and an upper cover 12 fixedly connected, and a porous material 13 fixed between the bottom plate 11 and the upper cover 12 .

[0038] The bottom plate 11 is made of copper, aluminum or steel, with a boss 111 on the upper surface, and a blind screw hole 112 on the lower surface corresponding to the boss 111 . The function of the boss 111 is to meet the processing space of the blind-end screw hole 112 on the other side. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com