Frequency converter IGBT module liquid cooling heat dissipation device of electric loader

A liquid-cooled heat dissipation and loader technology, applied in the direction of electric solid-state devices, circuits, electrical components, etc., can solve the problems that affect the normal operation of IGBT modules, poor heat dissipation, and low efficiency of air-cooled heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and examples.

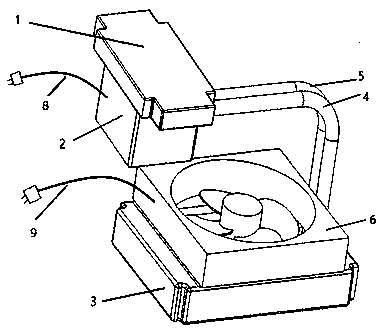

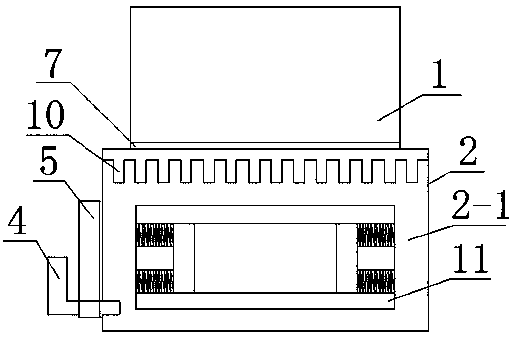

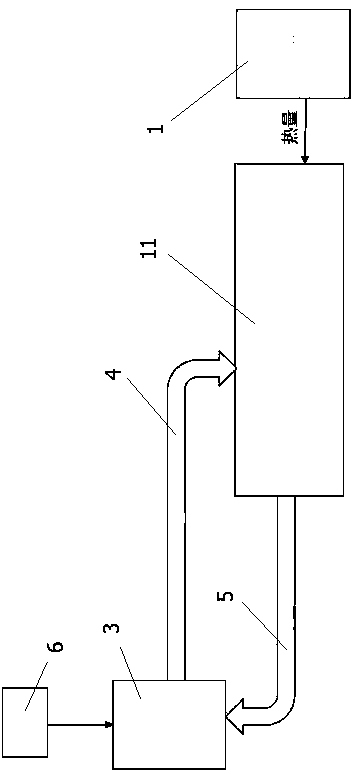

[0016] see figure 1 , This embodiment is a liquid-cooled heat dissipation device for an inverter IGBT module of an electric loader, which is composed of a water-cooled head 2, a radiator 3, a liquid inlet pipe 4, a liquid outlet pipe 5, and a fan 6. The water cooling head 2 is a closed rectangular box structure. The lower surface of the top panel of the water cooling head 2 is densely covered with a plurality of vertical cooling fins 10. Specifically, the material of the cooling fins 10 is copper or aluminum. The cooling fins 10 The contact area between the heat conducting copper surface and the cooling medium in the water cooling head 2 is increased. The IGBT module 1 is installed close to the upper surface of the top panel of the water cooling head 2, and the thermal conductive silicone grease is coated between the IGBT module 1 and the water cooling he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com