Device and method for producing trimethylene oxide by using electrolytic solution as saponification agent

A technology of propylene oxide and electrolyte, applied in the direction of organic chemistry, etc., can solve the problems of large amount of saponification waste residue, surrounding environmental pollution, inability to recycle waste water, etc., achieve low energy consumption, good permeability, and less steam consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

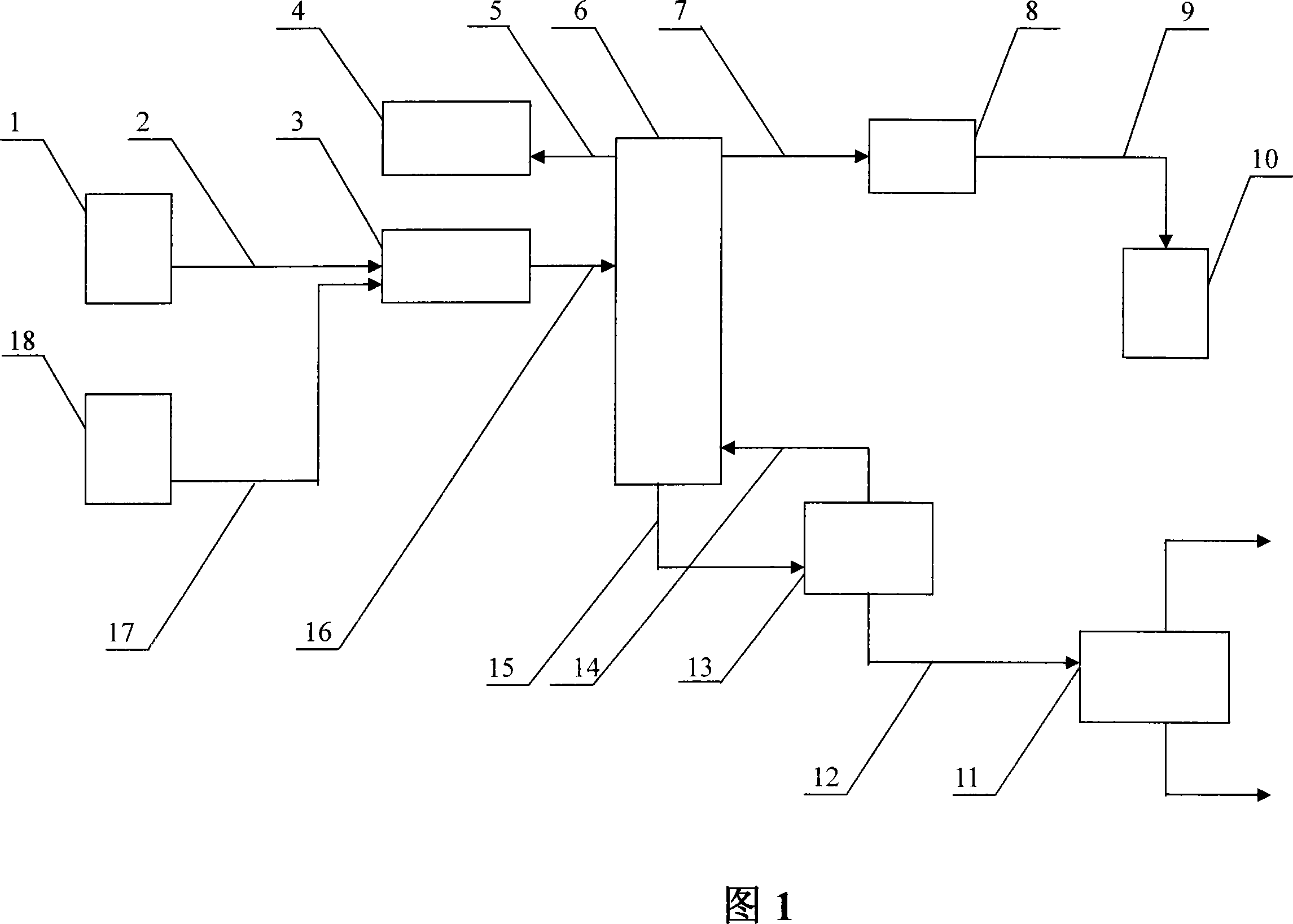

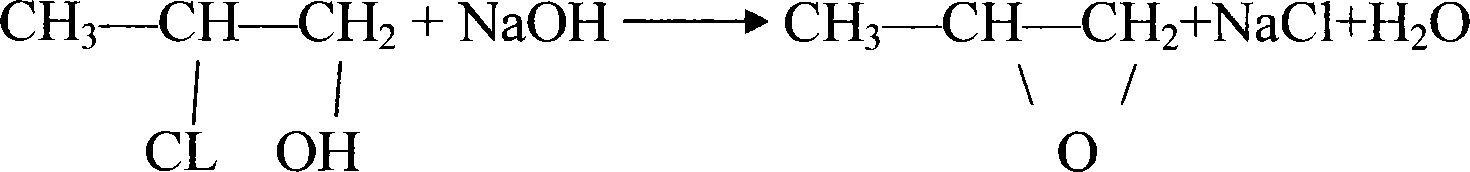

[0021] A device for producing propylene oxide using electrolyte as saponification agent, including chloropropanol storage tank 1, mixer 3, vacuum pump 4, saponification tower 6, condenser 8, crude propylene oxide storage tank 10, brine desalinator 11, flash Steam tank 13, electrolyte storage tank 18, chloropropanol storage tank 1 is connected with mixer 3 through chloropropanol pipeline 2; Mixer 3 is connected with saponification tower 6 through mixed liquid pipeline 16; Saponification tower 6 passes epoxy The propane vapor pipeline 7 is connected with the condenser 8, connected with the flash tank 13 through the saponification waste liquid pipeline 15 before flash evaporation, and connected with the flash tank 13 through the vapor recovery pipeline 14; the condenser 8 is connected with the crude propylene oxide pipe The road 9 is connected to the crude propylene oxide storage tank 10; the flash tank 13 is connected to the brine desalinator 11 through the saponified waste liqui...

Embodiment 2

[0029] Embodiment two is basically the same as embodiment one, the difference is:

[0030] (1) electrolyte concentration is controlled at 14WT%, and chloropropanol concentration is controlled at 5WT%, and the flow volume ratio of chloropropanol and electrolyte is 5: 1;

[0031] (2) saponification tower bottom temperature is controlled at 85 ℃;

[0032] (3) The top of the saponification tower is connected with a vacuum pump, so that the saponification tower is in a negative pressure state of 50KPa;

[0033] (4) The brine processor adopts low-temperature five-effect evaporation technology, the temperature of each effect is controlled at 60°C, 80°C, 100°C, 120°C, and 140°C, and the pure water treatment capacity is 220M 3 / H, concentrated brine treatment capacity is 220M 3 / H, the salt content of concentrated brine is 23WT%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com