Temperature control sludge drying system

A technology of sludge drying and temperature regulation, which is applied in the directions of sludge treatment through temperature control, water/sludge/sewage treatment, dehydration/drying/thickened sludge treatment, etc. No drying efficiency, no sludge drying, etc., to achieve the effect of simple structure, high energy utilization rate, and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

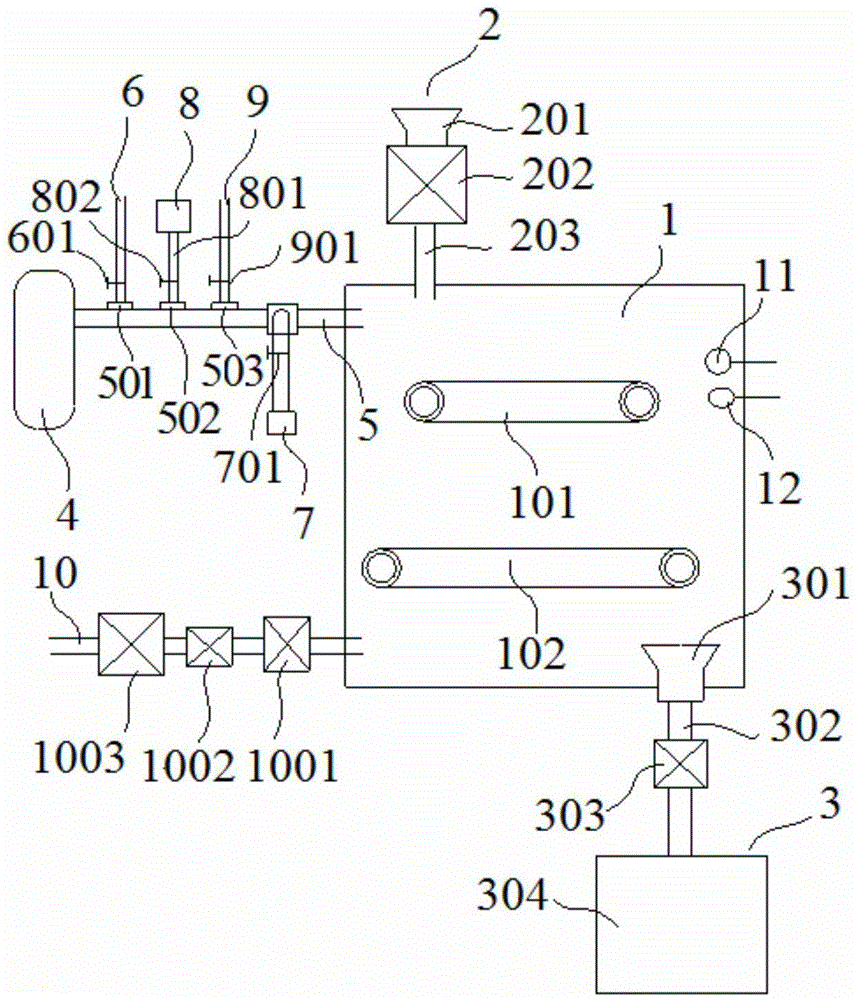

[0031] like figure 1 As shown, the temperature-regulated sludge drying system of the present invention includes:

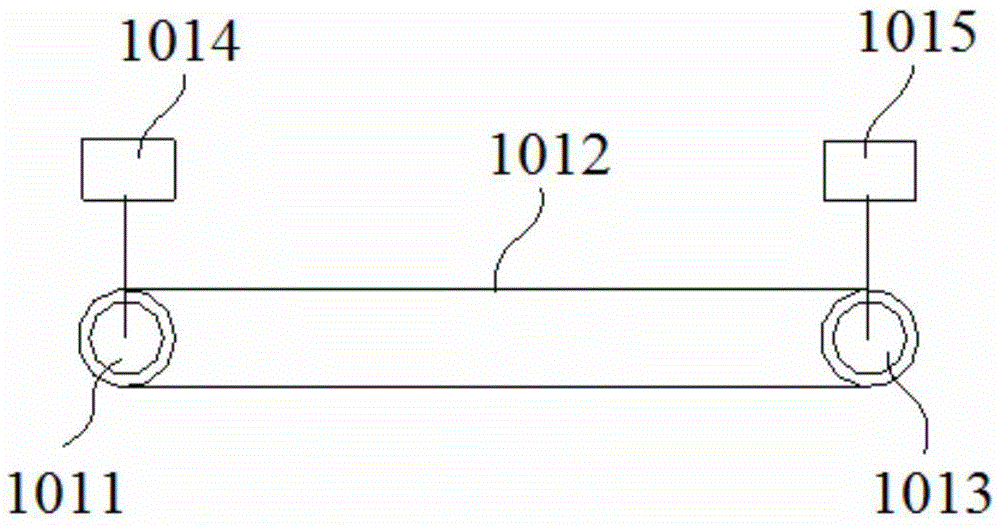

[0032] Dryer 1, the first sludge transfer device 101 and the second sludge transfer device 102 are arranged in the dryer 1, the first sludge transfer device 101 and the second sludge transfer device 102 have the same structure , the second sludge conveying device 102 is disposed below the first sludge conveying device 101 , and the conveyor belt of the second sludge conveying device 102 is longer than the conveyor belt of the first sludge conveying device 101 . like figure 2 As shown, the first sludge transfer device 101 includes a first transfer wheel 1011, a transfer belt 1012, and a second transfer wheel 1013. The first transfer wheel 1011 is connected to a first motor 1014, and the second transfer wheel 1013 is connected to There is a second motor 1015 .

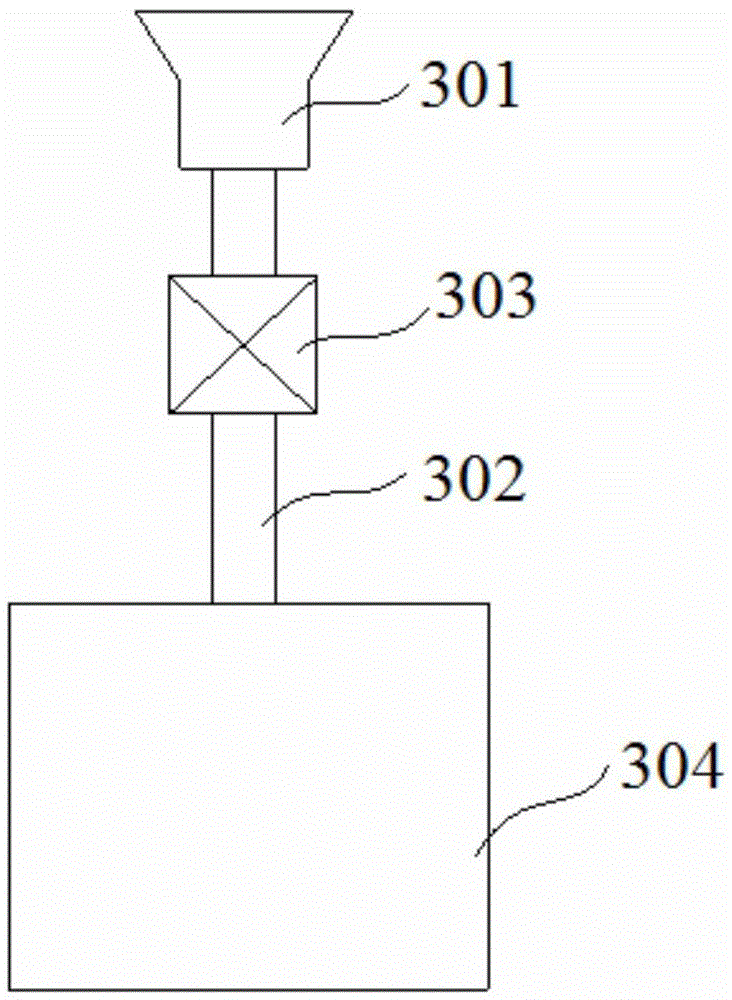

[0033] Feed device 2, shown feed device 2 comprises feed inlet 201, extruder 202, feed pipeline 203, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com