Steam power plant with steam turbine unit and process steam consumer, and method for operating a steam power plant with steam turbine unit and process steam consumer

a technology of steam turbine unit and steam power plant, which is applied in the direction of steam use, mechanical equipment, machines/engines, etc., can solve the problems of high steam temperature, high energy consumption of such high-temperature steam, and inability to meet the needs of steam power plant operation, etc., to achieve the effect of reducing the cost improving the overall efficiency of steam power plant, and shortening the piping rou

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

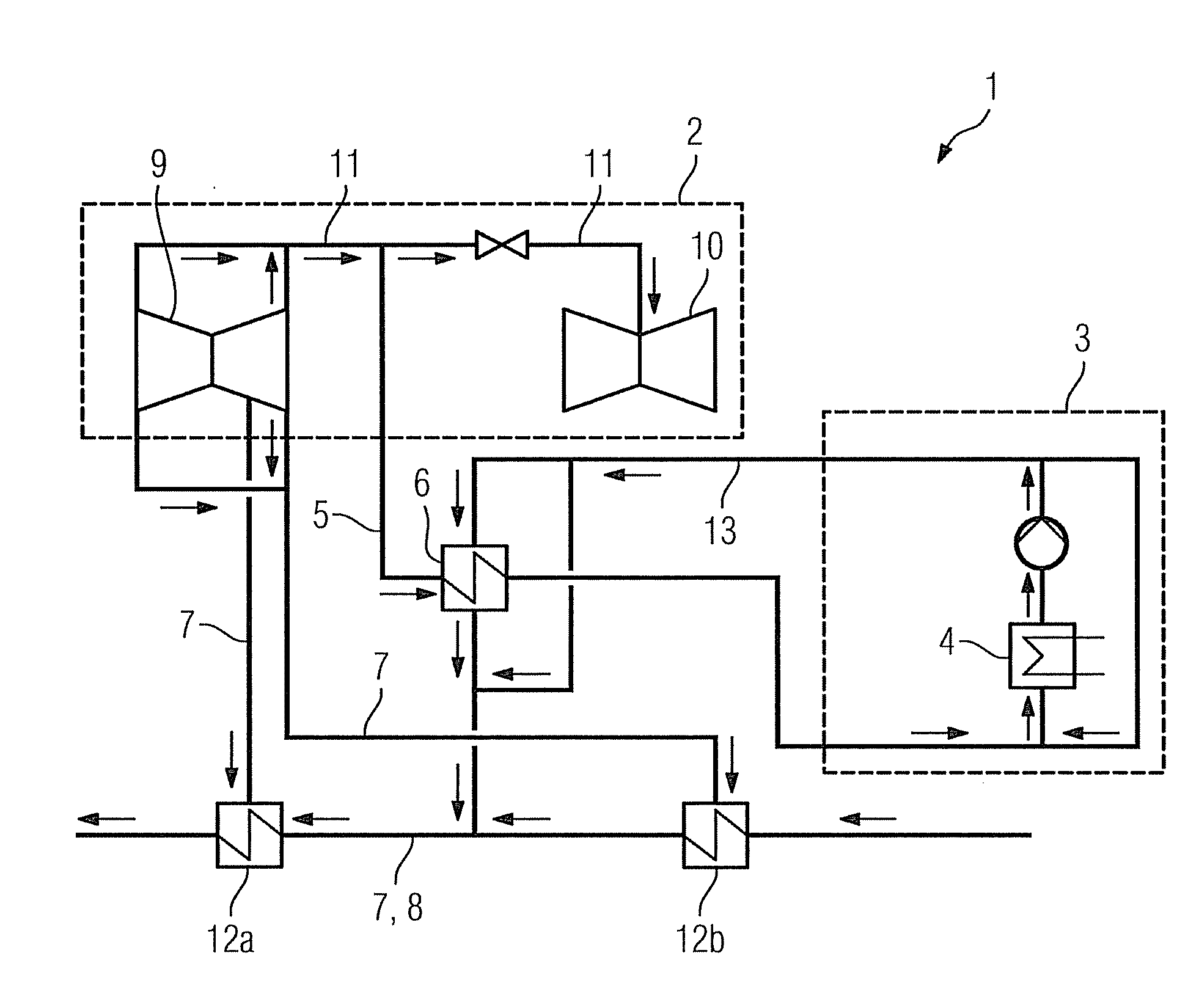

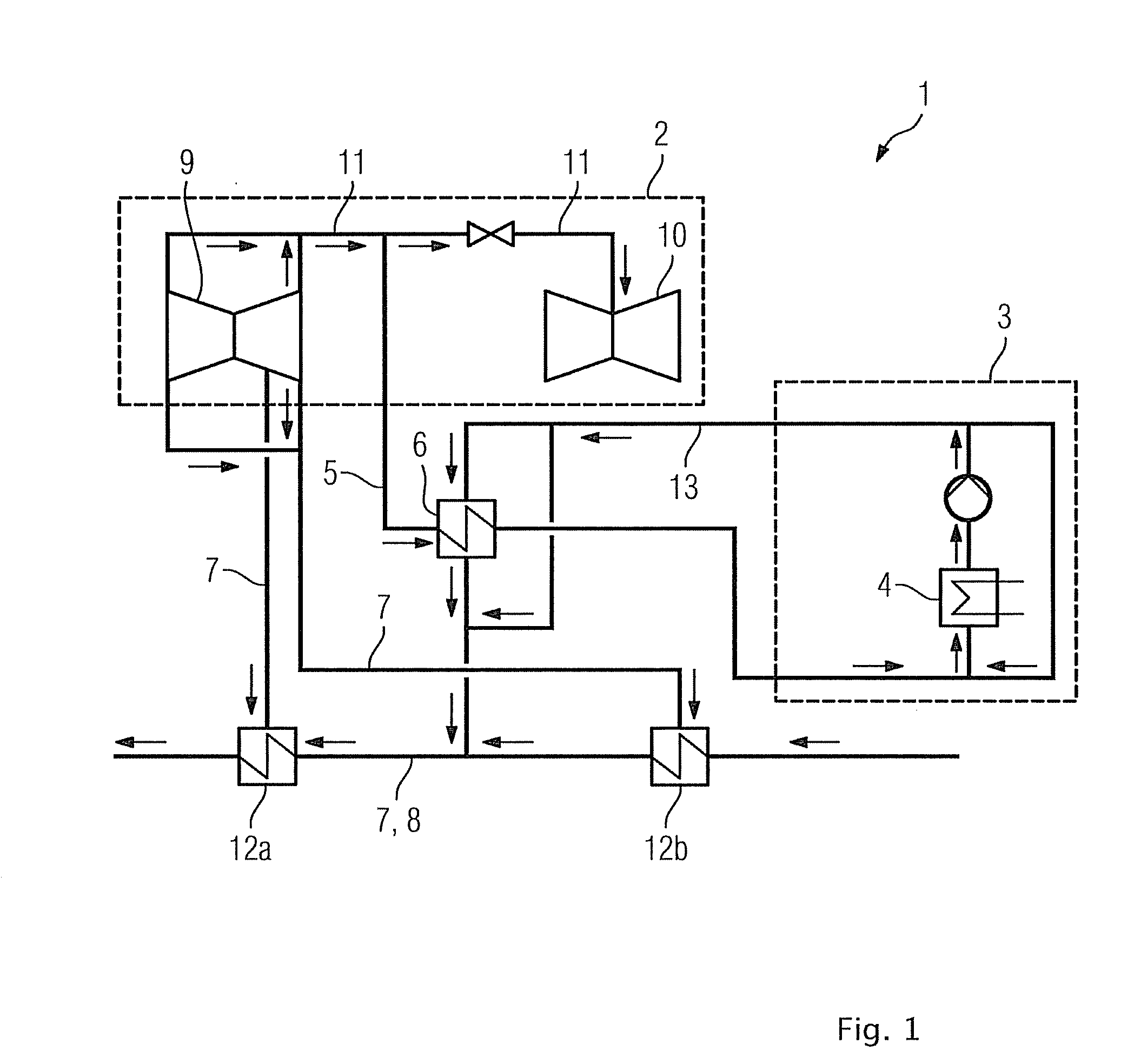

[0021]The steam power plant 1 which is shown in FIG. 1 essentially shows a steam turbine unit 2 and a process steam consumer 3 and also a desuperheater 6.

[0022]The steam turbine unit 2 shows an intermediate-pressure turbine 9 and a low-pressure turbine 10, which are interconnected via a crossover line 11. During operation of the steam power plant 1, superheated steam leaving the intermediate-pressure turbine 9 can therefore be transferred into the low-pressure turbine 10. The bleed line 5 is connected to the crossover line 11. Some of the superheated steam can be branched off from the crossover line 11 through the bleed line 5.

[0023]The bleed line 5 is furthermore connected to the desuperheater 6 on the primary feed side. On the primary discharge side, the desuperheater 6 is connected to the process steam consumer 3. By means of the desuperheater 6, heat is extracted from superheated steam which is guided in the bleed line 5. Slightly superheated steam leaves the desuperheater on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com