steam box

A technology of steaming box and box body, applied in the field of steaming box, can solve the problems of low rice steaming efficiency, complex structure, transmission error, etc., and achieve the effects of improving rice steaming efficiency, precise control, and improving accuracy and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

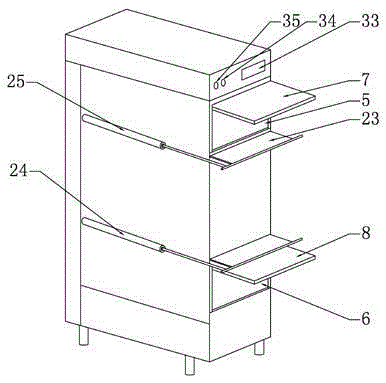

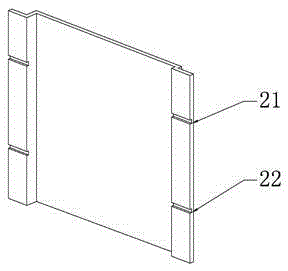

[0034] Embodiment 1: a kind of steamer, see Figure 1 to Figure 7 ; Including box body 1, tray 2, linear stepping motor 3, two movable partitions, the two movable partitions in the box body divide the box body from top to bottom into a disc chamber 30, a working room 4, an inlet Disk chamber 36 is provided with the disk inlet 6 communicating with the disk chamber 36 and the disk outlet 5 with the disk chamber 30 on the front side of the casing; Each corresponding hinge is provided with dodge door 8,7, is respectively provided with a movable partition chute 22,21 above the inlet 6 and the outlet 5 below the left and right sides of the casing inboard, and in the steam box There are two movable partition entrances and exits correspondingly connected with the two movable partition chutes 22, 21 on the front wall of the front wall, and the two movable partitions enter the corresponding movable partition chutes 22, 21 respectively through the corresponding movable partition entrance...

Embodiment 2

[0040] Embodiment 2, the same as Embodiment 1 will not be stated again, the difference is that: the support table includes a rotating shaft installed on the bracket, a support plate installed on the rotating shaft, and a There is an elastic soft rubber cylinder, and each support plate can only rotate upwards around its corresponding rotating shaft, and bounces back and resets to a horizontal position through the soft rubber cylinder; the lifting platform passes through its corresponding The rotating shaft is connected to the lifting member in a corresponding rotation, and an elastic soft rubber cylinder is arranged on the lifting platform; It springs back to the horizontal position.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com