Steam turbine exhaust steam moisture on-line measurement device

A technology of exhaust steam humidity and measuring device, which is applied in the direction of using microwaves to test moisture content, mechanical equipment, engine components, etc., can solve problems such as limited application and pollution, and achieve the effects of strong environmental adaptability, high measurement accuracy and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

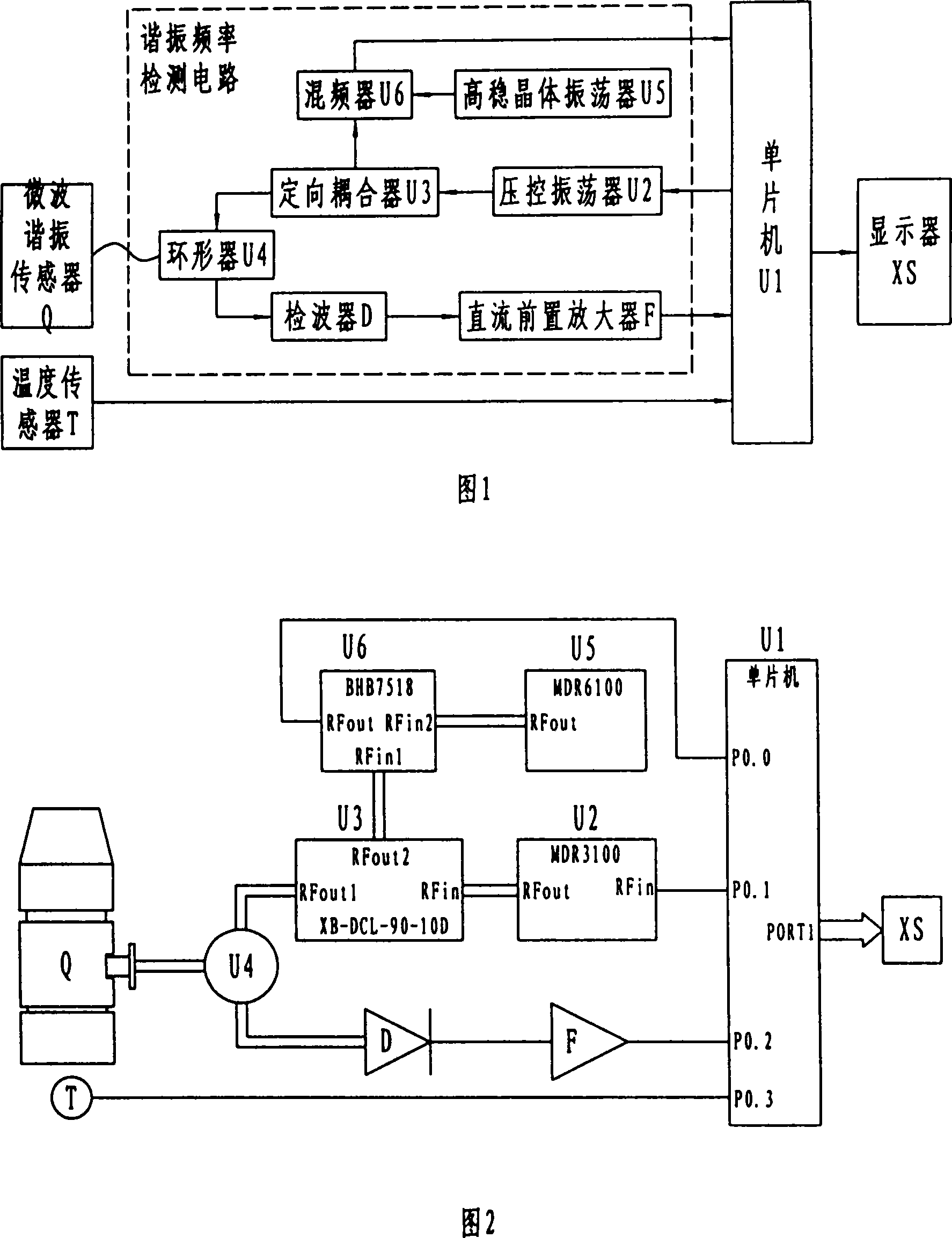

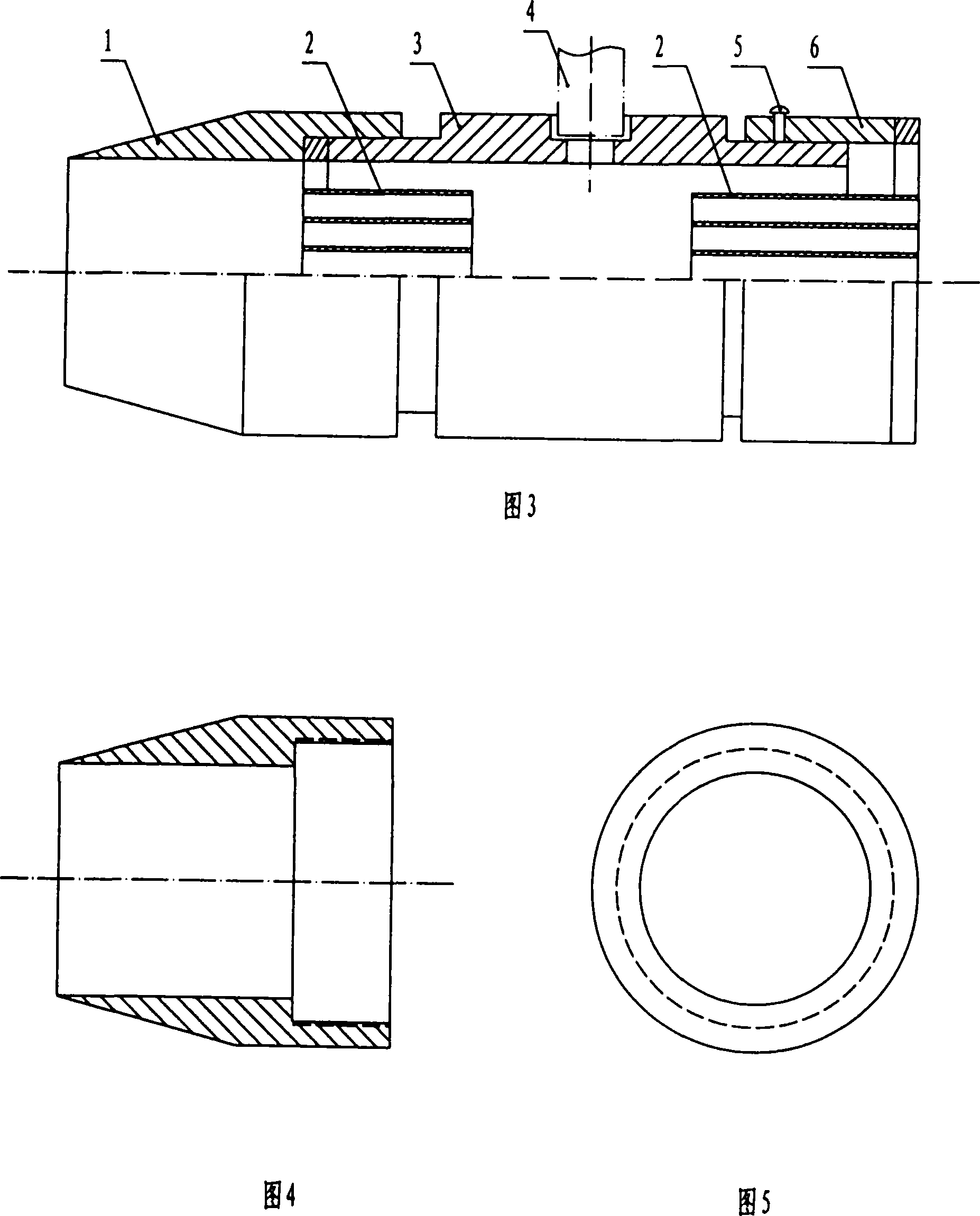

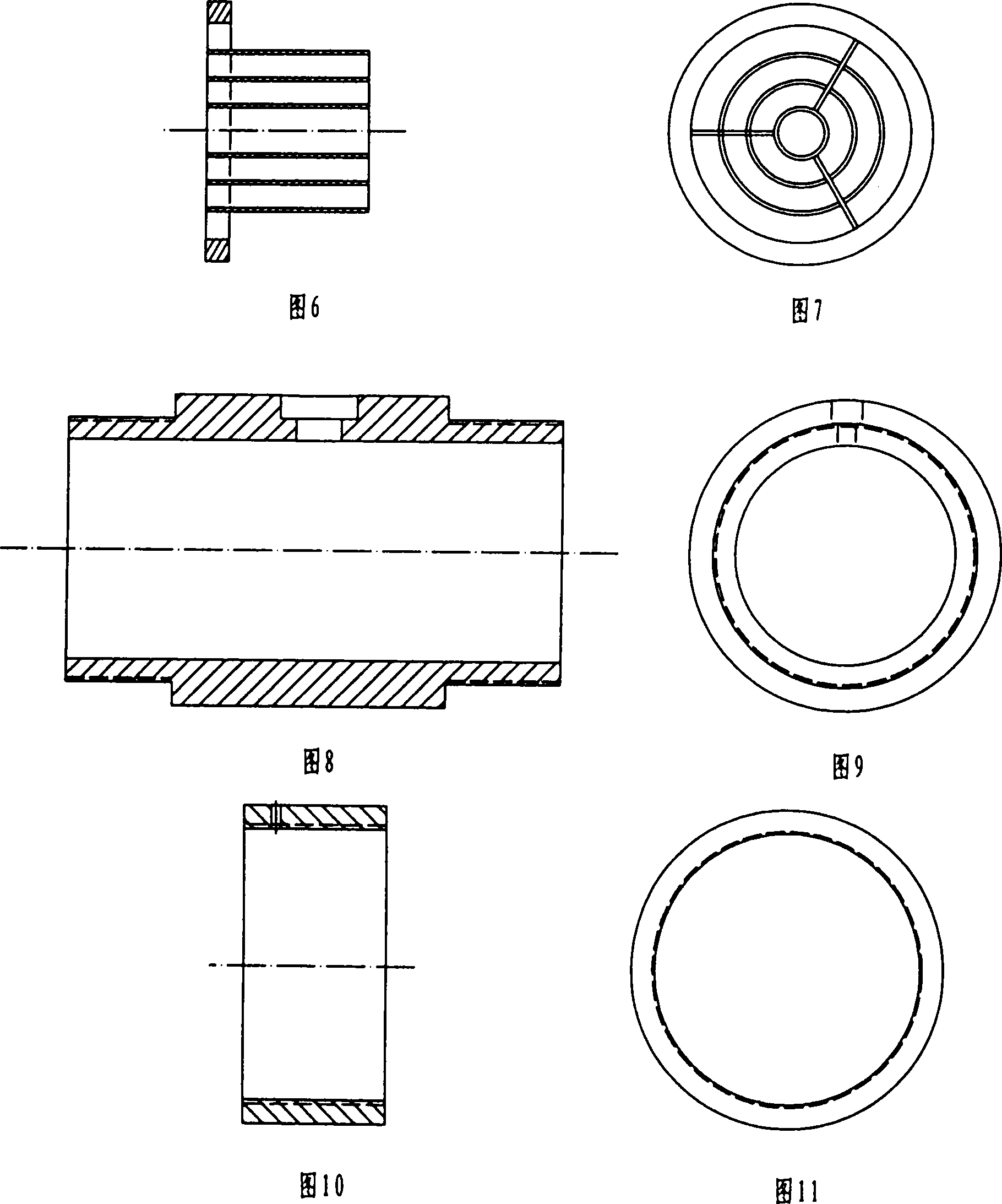

[0030] The present invention proposes a brand-new technology for on-line measurement of steam turbine exhaust humidity based on microwave resonant cavity perturbation. The invention is mainly based on the following ideas:

[0031] Turbine exhaust steam is a steam-water mixture composed of dry saturated steam and a large number of fine mist droplets. Since the dielectric constant of gaseous water and liquid water is very different, the humidity of steam turbine exhaust is different, and its dielectric constant is also different. . For microwaves of a certain frequency, under the condition of constant pressure and temperature, the dielectric constant of the exhaust steam of the steam turbine only depends on the humidity of the exhaust steam. Therefore, the measurement of the humidity of the exhaust steam of the steam turbine can be realized by measuring the dielectric constant of the exhaust steam of the steam turbine. .

[0032] A small change in the dielectric constant of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com