Hollow turbine blade

一种透平叶片、叶型的技术,应用在叶片的支承元件、发动机元件、机器/发动机等方向

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

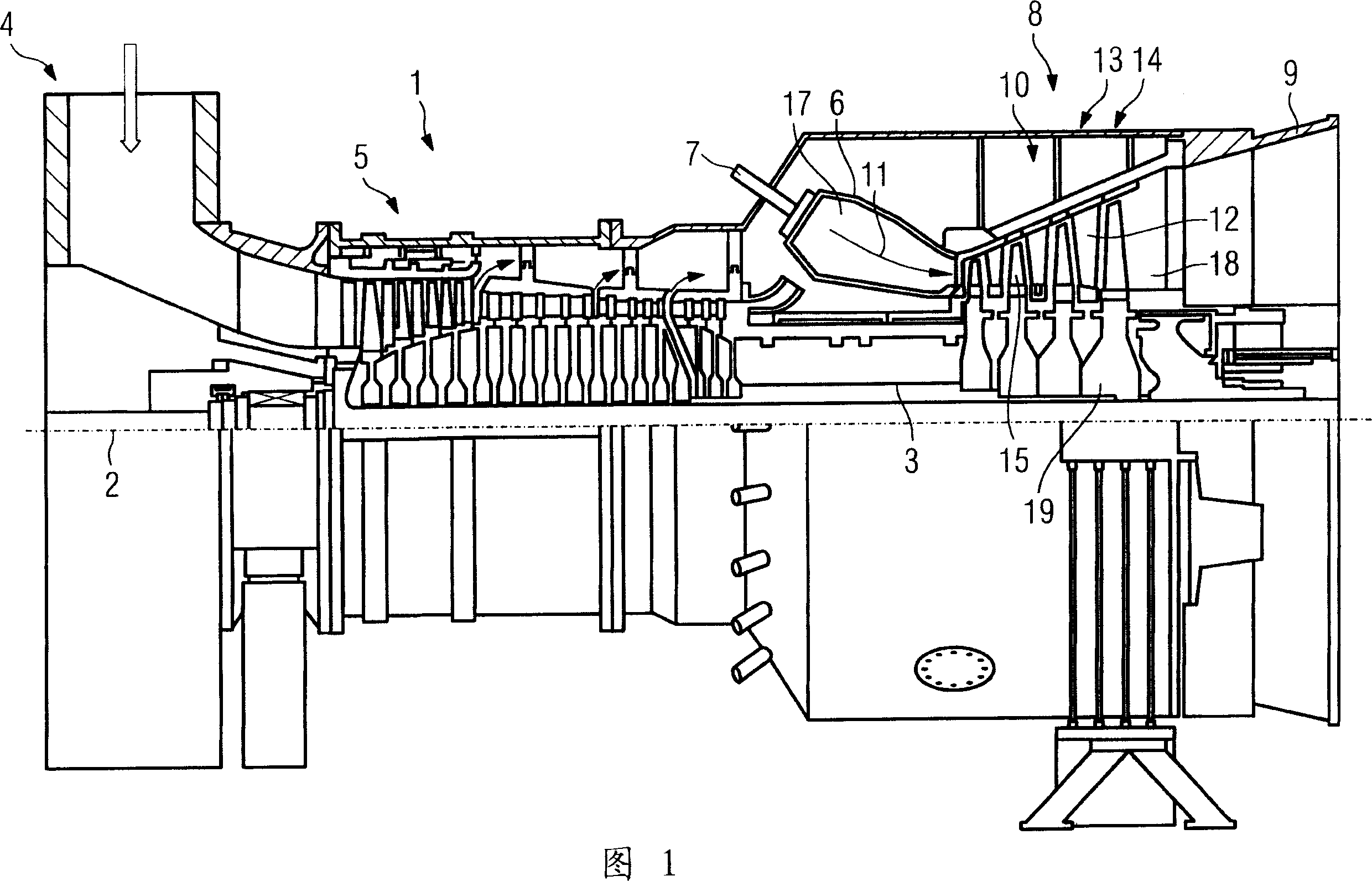

[0016] FIG. 1 shows a gas turbine 1 in a longitudinal partial section. The gas turbine internally has a rotor 3 mounted rotatably about an axis of rotation 2 , which is also referred to as a turbine rotor. Along the rotor 3 there are successively a suction housing 4 , a compressor 5 , an annular combustion chamber 6 with a plurality of burners 7 arranged rotationally symmetrically to one another, a turbine unit 8 and an outlet housing 9 . The annular combustion chamber 6 forms a combustion chamber 17 which communicates with an annular hot gas channel 18 . Here, four successively connected turbine stages 10 form the turbine unit 8 . Each turbine stage 10 consists of two blade rings. Viewed along the flow direction of the hot gas 11 generated in the annular combustion chamber 6 , each guide vane group 12 is followed by a respective rotor blade group 14 formed of rotor blades 15 in the hot gas channel 18 . The guide vanes 12 are attached to the stator, while the rotor blades 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com