Pressure reduction gas desulfurization method

A gas and recovery tank technology, applied in the petroleum industry, gas fuel, fuel and other directions, can solve the problems of heating furnace and pipeline corrosion, poor desulfurization effect, compressor corrosion, etc., to achieve less construction investment, convenient operation, and low failure rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with embodiment.

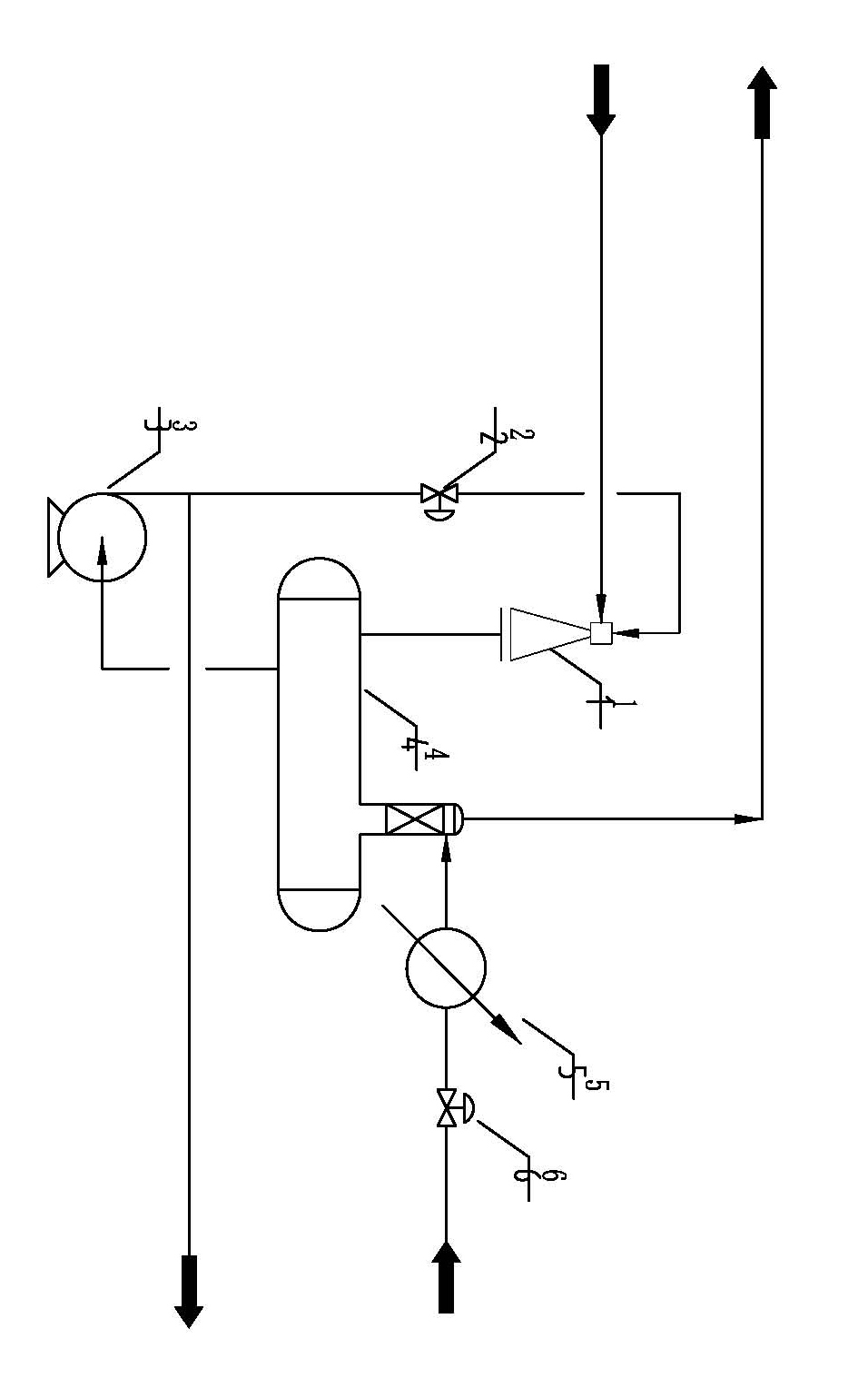

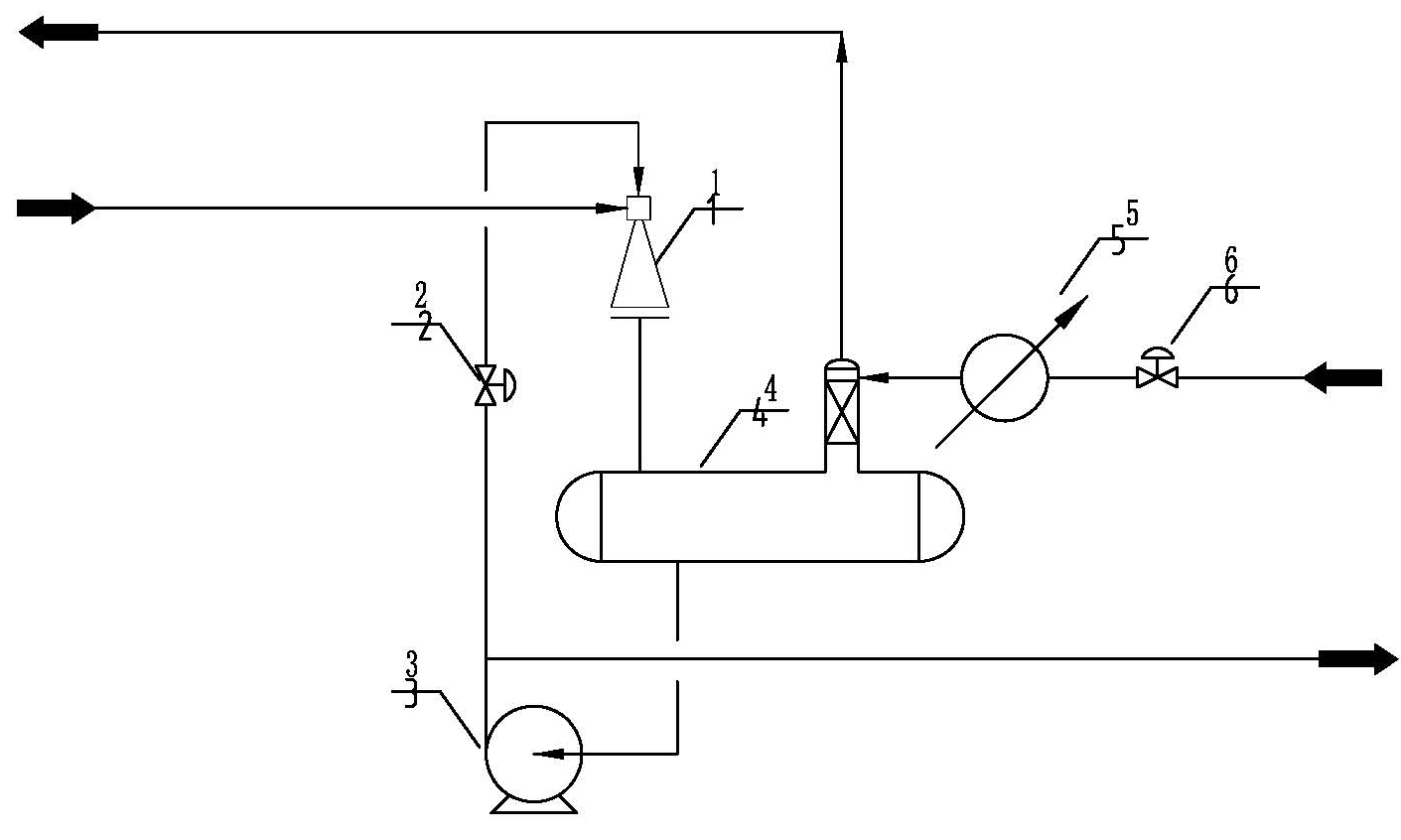

[0022] In the vacuum gas desulfurization method described in the present invention, the absorbent is circulated by the circulation pipeline, the circulation pump 3 and the recovery tank 4 are connected in the circulation pipeline, the injector 1 is connected on the upstream circulation pipeline of the recovery tank 4, and the sulfur-containing gas is connected On the ejector 1, the top of the recovery tank 4 is provided with a purified gas outlet, and the purified gas outlet at the top of the recovery tank 4 is equipped with a structured packing, and an absorbent supply pipe is connected to the purified gas outlet, and the absorbent supply pipe is used for Add new absorbent, connect the absorbent discharge pipe on the upstream circulation pipeline of the recovery tank, and the absorbent discharge pipe is used to discharge the absorbed absorbent to ensure the absorption effect of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com