Sinter-smoke circulation collected desulfurizing method and apparatus

A technology for sintering flue gas and desulfurization devices, applied in the field of desulfurization devices, can solve the problems of large flue gas treatment capacity, large engineering investment, and high operating costs, and achieve the effects of saving operating costs, saving engineering investment, and improving desulfurization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

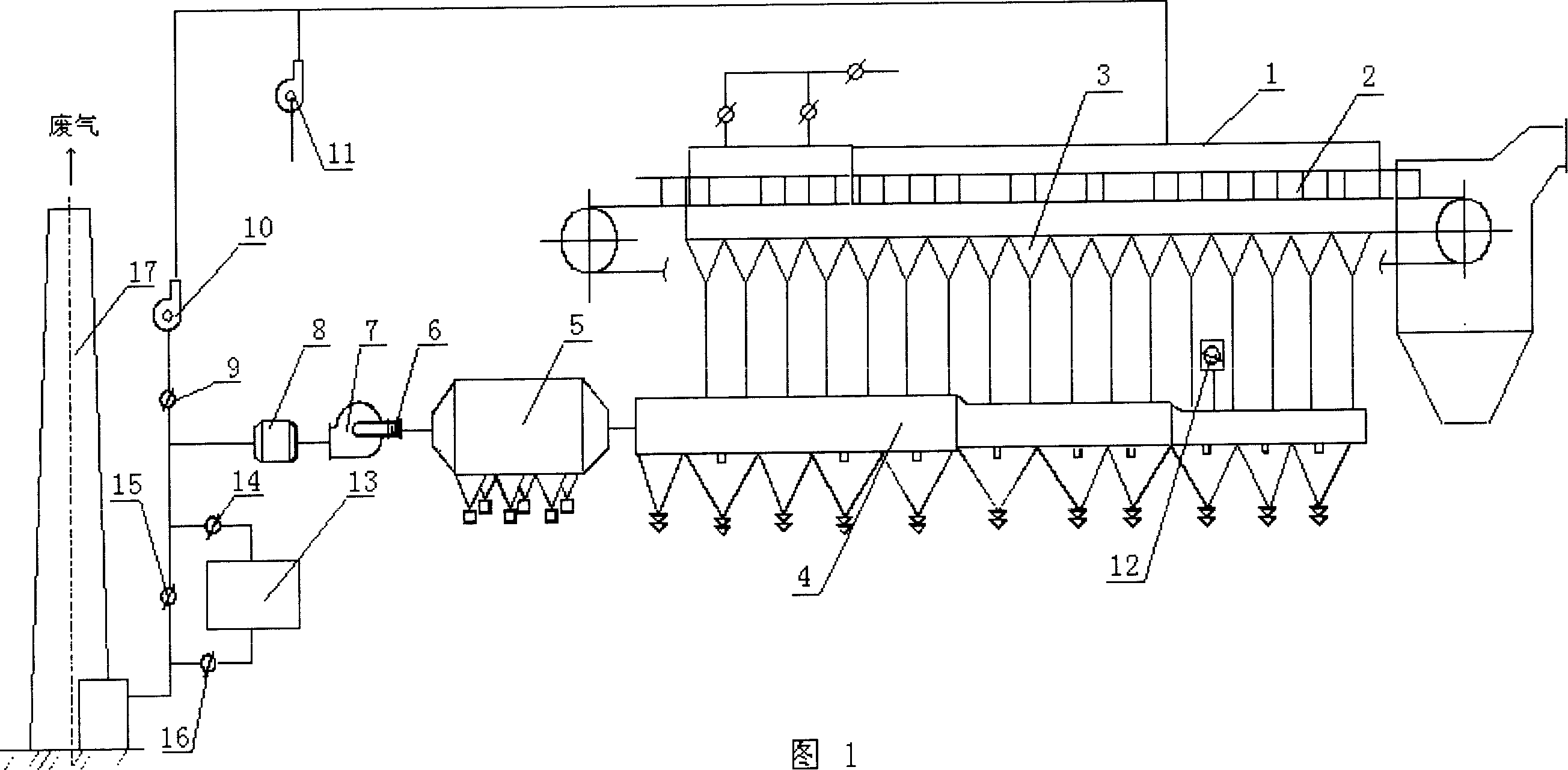

[0023] The sintering flue gas cycle enrichment desulfurization method for single flue is: take about 50% of the flue gas from the flue of the sintering machine and return it to the upper sealing cover of the sintering machine for circulation, and at the same time supplement the oxygen required for the combustion of the sintering machine, The rest of the flue gas is discharged after desulfurization treatment.

Embodiment 2

[0025] As shown in Figure 1. The sintering flue gas circulation enrichment desulfurization device for single flue includes sintering machine sealing cover 1, sintering machine trolley 2, sintering machine bellows 3, sintering machine large flue 4, dust collector 5, fan inlet regulating valve 6, main Exhaust fan 7, muffler 8, flue baffle switching valve 9, circulation fan 10, oxygen supply fan 11, cold air suction valve 12, flue baffle switching valve 14, flue baffle switching valve 15, flue baffle switching Valve 16, desulfurization process device 13 (existing desulfurization process devices can be used, including wet, dry and semi-dry methods of calcium method, ammonia method, organic amine method, seawater method and other process devices), chimney 17. A sealing cover 1 is added to the upper part of the sintering machine trolley 2, the lower part of the trolley 2 is connected to the bellows 3 of the sintering machine, the bellows 3 are collected to the flue 4, the cold air s...

Embodiment 3

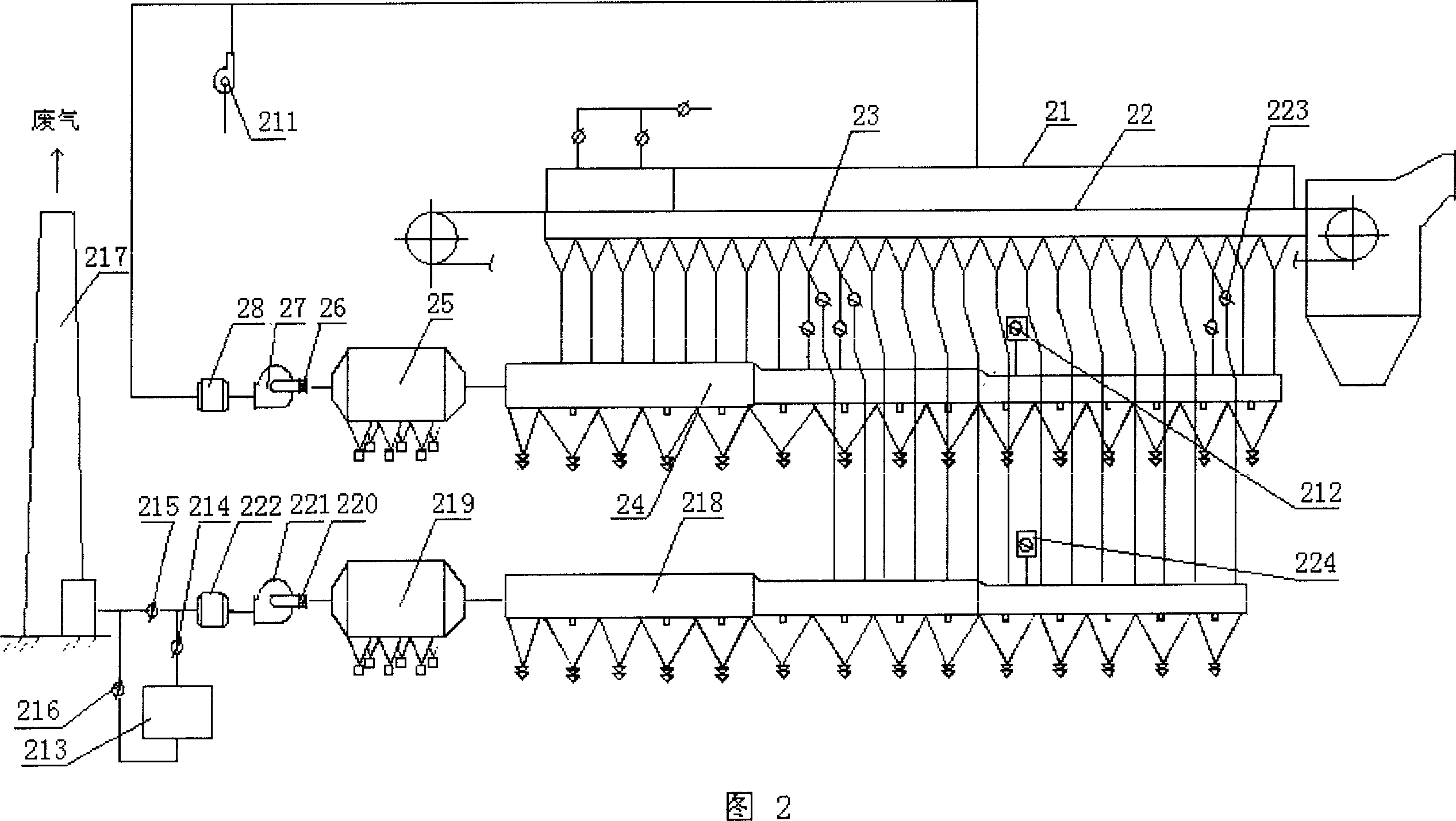

[0028] The sintering flue gas circulation enrichment desulfurization method for double flue is as follows: the sintering machine uses two flues, and one flue takes a part of low-concentration SO from the head and tail wind boxes of the sintering machine. 2 The flue gas returns to the sealed cover on the upper part of the sintering machine for circulation, and at the same time supplements the oxygen required for the combustion of the sintering machine, and uses another flue to reduce the high concentration of SO in the middle wind box of the sintering machine 2 The flue gas is discharged after desulfurization treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com