Method for producing synthesis gas by microwave gasification of biochar

A technology of biochar and synthesis gas, which is applied in the direction of granular/powdered fuel gasification, educts, and production of combustible gas. The effect of reducing content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

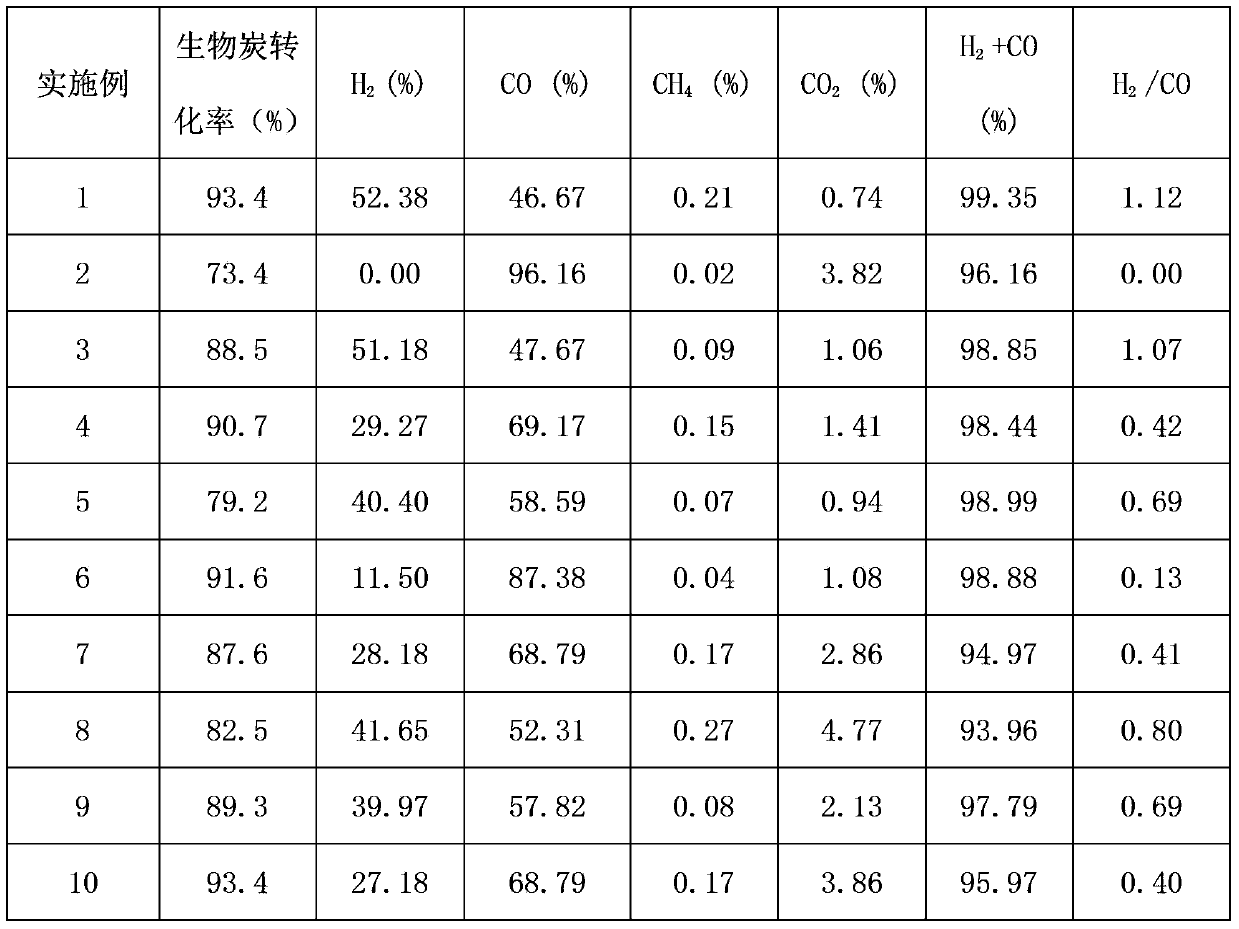

[0026] The rice straw was completely pyrolyzed at about 500 °C, and the biochar was collected after cooling, and mixed with 5% K 2 O was mechanically mixed, crushed to 0.5 mm particles, and filled into a quartz gasification reactor. With microwave as heat source, at 10ml / min N 2 The biochar solid mixture was heated to 900°C and kept for 30 min, then the carrier gas N 2 Switch to water vapor with a space velocity of 4000h -1 , the gasification reaction is carried out at 900 ° C, and the generated gas is cooled to be the synthesis gas product. The gas composition is detected by gas chromatography (Shimadzu 2014C, TCD detector, Ar is the carrier gas, TDX-1 packed column, and the column oven temperature is 100°C), the test results are shown in Table 1.

Embodiment 2

[0028] The wheat straw is completely pyrolyzed at about 500°C, and the biochar is collected after cooling, and the mass fractions of CaO and SiO are 5% respectively. 2 Mechanically mixed, crushed to 1.5 mm particles, and filled into a quartz gasification reactor. Using microwave as the heat source, the biochar solid mixture was heated to 500 °C under 40 ml / min Ar, and after keeping for 50 min, the carrier gas Ar was switched to CO 2 , the airspeed is 100h -1 , the gasification reaction is carried out at 500°C, and the generated gas is cooled to be the synthesis gas product. The gas composition is detected by gas chromatography (Shimadzu 2014C, TCD detector, Ar is the carrier gas, TDX-1 packed column, and the oven temperature is 100°C), the test results are shown in Table 1.

Embodiment 3

[0030] The cotton stalks are completely pyrolyzed at about 500 °C, and the biochar is collected after cooling, and the mass fractions are 1% MgO and 9% Fe 2 o 3 Mechanically mixed, crushed to 1.0 mm particles, and filled into a quartz gasification reactor. With microwave as heat source, at 30ml / min N 2 The biochar solid mixture was heated to 700°C and kept for 30 min, then the carrier gas N 2 Switch to water vapor, the space velocity is 2000h -1 , the gasification reaction is carried out at 700°C, and the generated gas is cooled to be the synthesis gas product. The gas composition is detected by gas chromatography (Shimadzu 2014C, TCD detector, Ar is the carrier gas, TDX-1 packed column, and the oven temperature is 100°C), the test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com