Coal horizontal rotation dry distillation process and equipment

A horizontal, dry distillation technology, applied in the field of coal chemical industry, can solve the problems of blockage of pipelines by solid materials, low heat utilization rate, low gas calorific value, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

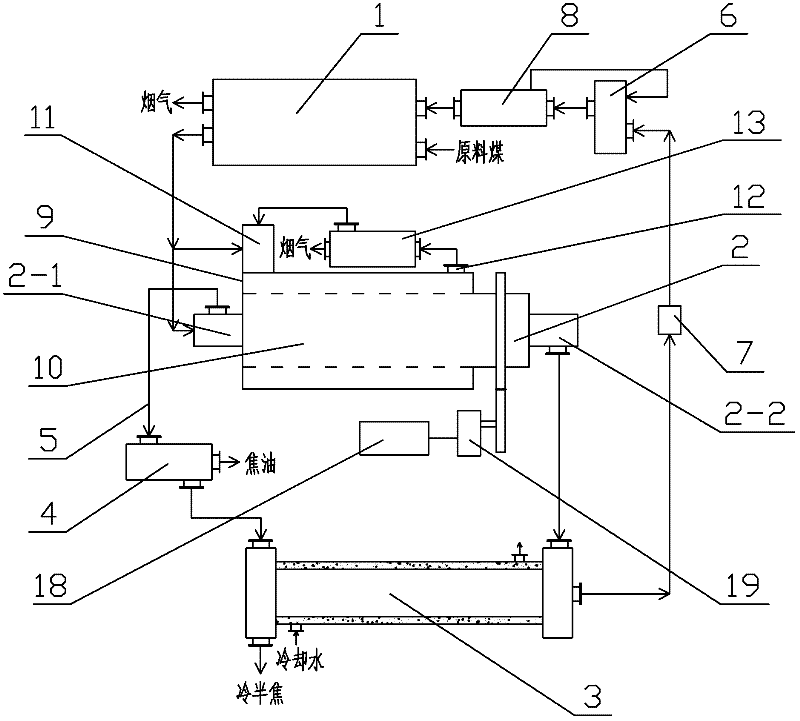

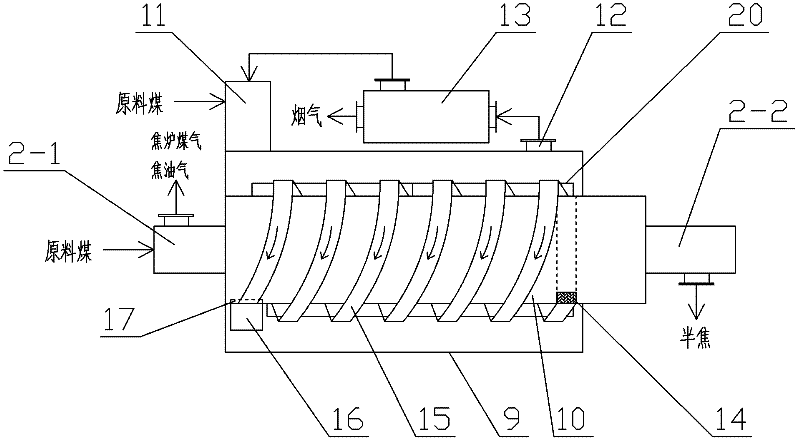

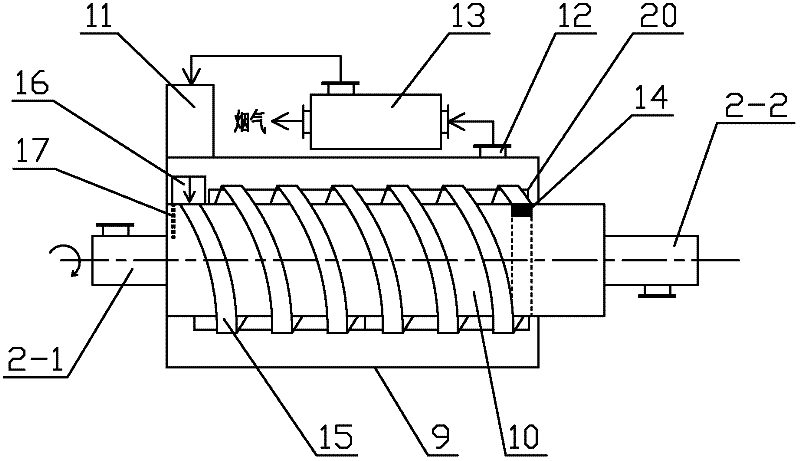

[0044] Such as figure 1 Shown is a coal horizontal rotary carbonization equipment, which includes a drier 1 for drying and preheating coal, and a horizontal rotary retort connected to the discharge port of the drier 1 for carbonization and pyrolysis of coal Dry distillation furnace 2; the horizontal rotary dry distillation furnace 2 includes a feed section 2-1, a dry distillation section and a discharge section 2-2, and the outlet of the discharge section 2-2 is arranged at one end of the semi-coke cooler 3 The feed port is connected, and a coke filter is provided between the discharge port of the feed section 2-1 for discharging coke oven gas and tar gas produced by carbonization and pyrolysis and the gas desulfurization filter 4 inlet port. The pipeline 5 equipped with a catalyst for the cracking and lightening of furnace gas and tar gas, the exhaust port of the gas desulfurization filter 4 is connected with the air inlet arranged at the other end of the semi-coke cooler 3, ...

Embodiment 2

[0051] Adopt the equipment of embodiment 1 to carry out horizontal rotary dry distillation to coal:

[0052] Step 1. Pass the hot flue gas produced by the gas generator 6 into the air heat exchanger 8 to perform countercurrent indirect heat exchange with the air, and send the heat-exchanged air as combustion-supporting air into the gas generator 6 for combustion and power generation. The flue gas discharged from the flue gas outlet of the air heat exchanger 18 with a temperature not less than 400°C and the raw coal (Shenmu crushed coal with a particle size not greater than 30mm) are sent to the dryer 1 together, through the contact flow heat exchange method Drying and preheating the raw coal until the temperature of the raw coal is not lower than 250°C;

[0053] Step 2: Send 10% of the total weight of raw coal preheated in step 1 into the hot blast stove 11 for combustion, and use the flame generated by the combustion to heat the annular space formed between the outer cylinder...

Embodiment 3

[0061] The process of this example is the same as that of Example 2, except that the solid carrier used is quartz sand, iron oxide powder, semi-coke or other granular oxide catalysts.

[0062] In the process of this embodiment, the generated flue gas and semi-coke waste heat are rationally utilized, and the heat utilization rate is high, and the generated gas is used to generate electricity to realize the self-sufficiency of equipment power; at the same time, cold coal gas coke is used, and the semi-coke waste heat is utilized. Compared with the semi-coke produced by the traditional method, the produced semi-coke does not contain water, has high quality and wide application, and the produced tar has high yield and good quality. The specific results are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com