Lng bog reliquefaction apparatus

A technology for re-liquefaction and liquefaction of natural gas, applied in the direction of liquefaction, refrigeration and liquefaction, electrical components, etc., can solve problems such as unfavorable and rapid coping with conditions, changes, blade damage of turbines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

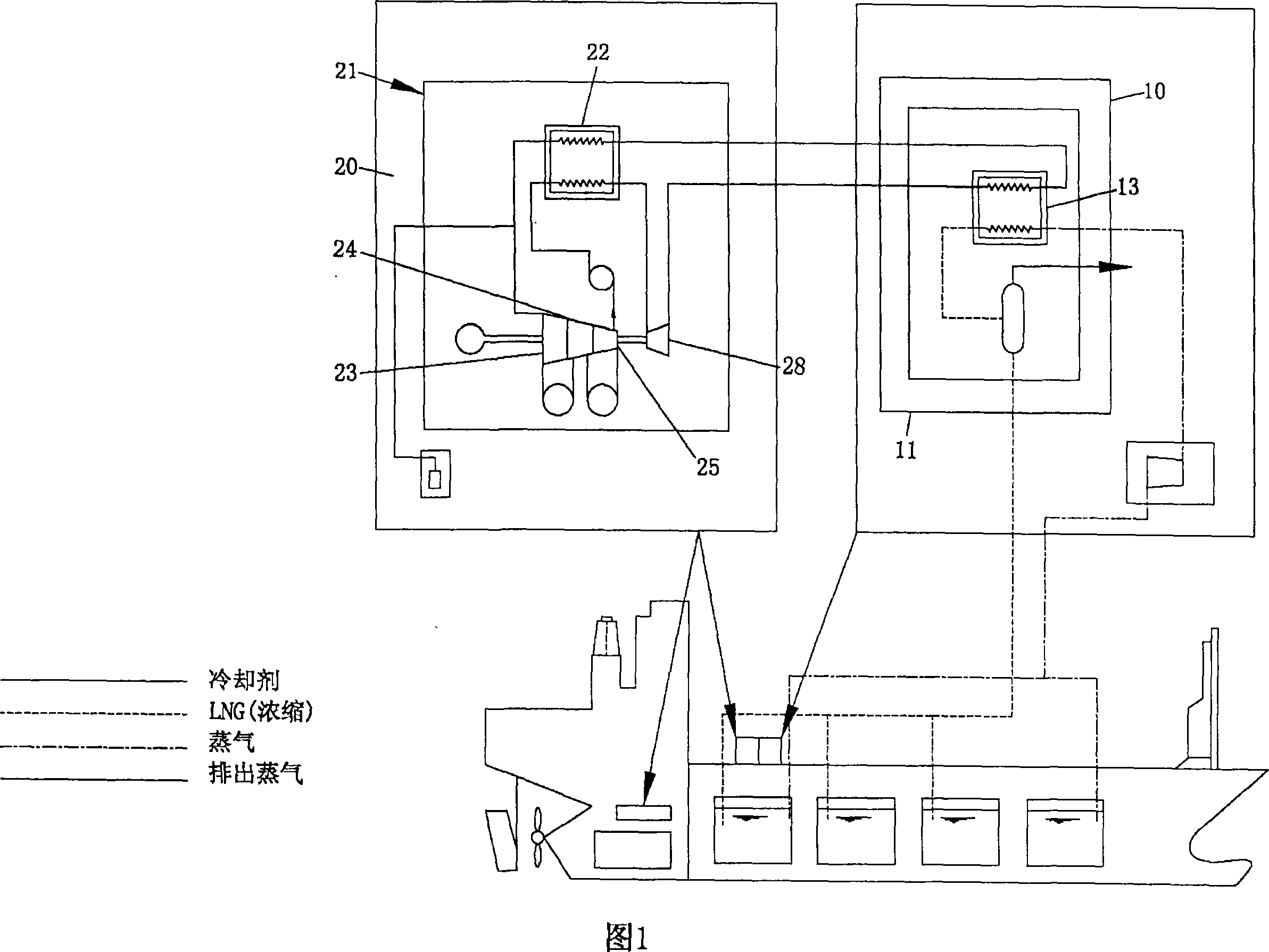

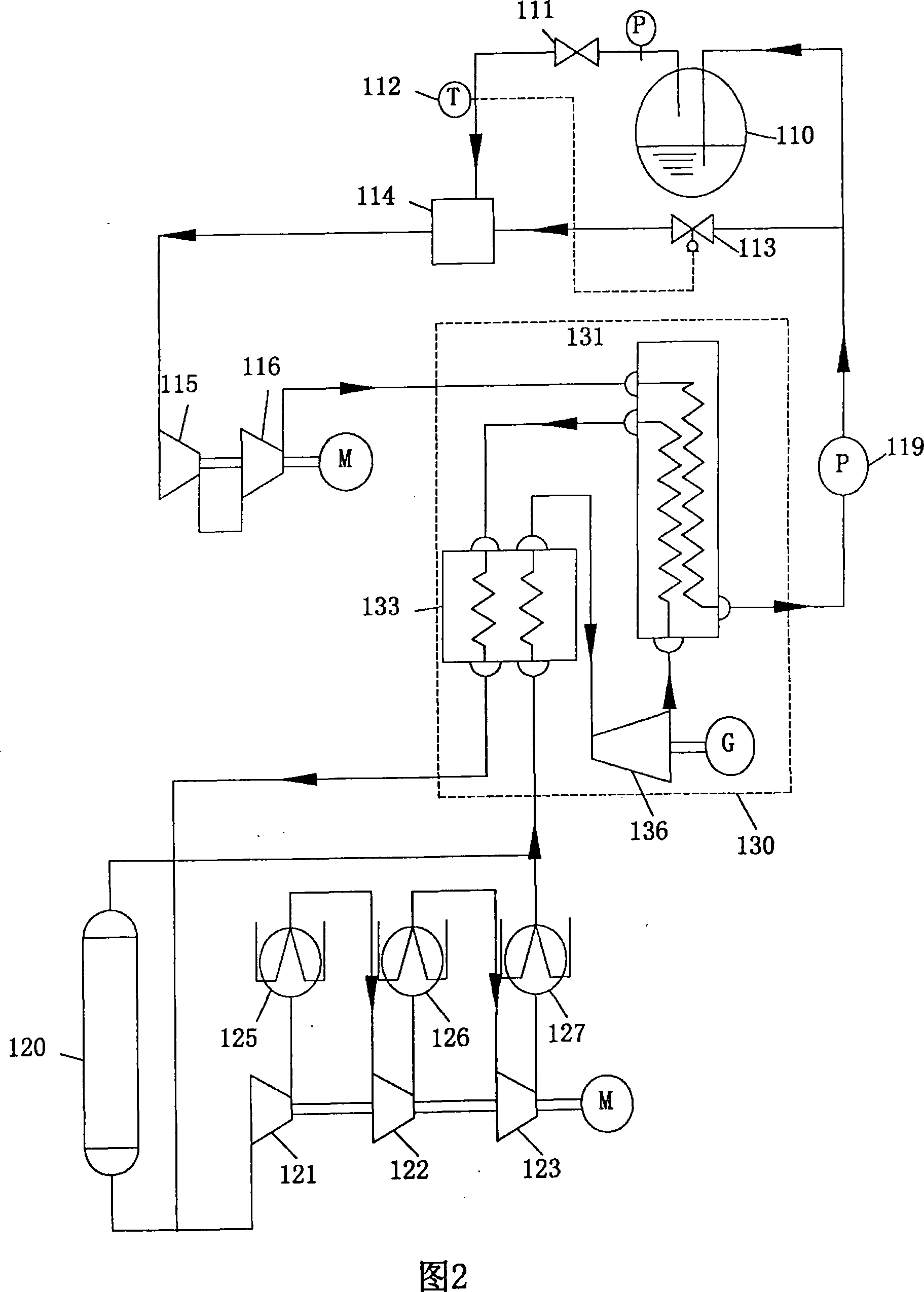

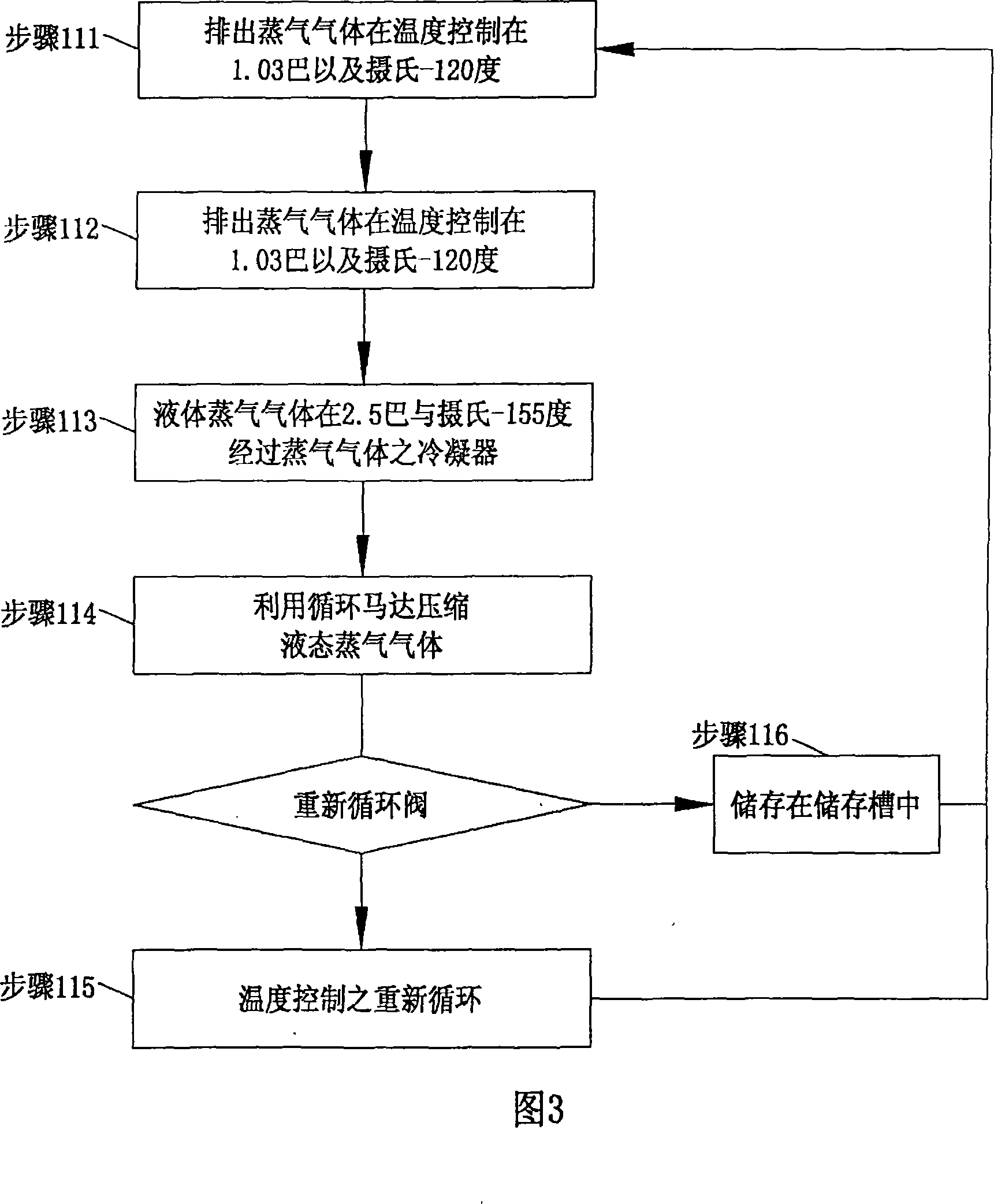

[0078] The present invention will be described in detail with reference to FIGS. 2 to 13 . The following description is only made in connection with a more similar embodiment of the present invention. Temperatures and pressures are represented herein and the invention is not limited to these values.

[0079] The apparatus and method of the present invention for reliquefying LNG vapor according to the first embodiment of the present invention are described in detail with reference to FIGS. 2 to 4 .

[0080] Vapor Coil Apparatus Natural gas is liquefied in a gas phase and stored in a storage tank 110 at a low temperature at atmospheric pressure (1.013 bar). During the transportation of LNG, the vapor is caused due to the continuous heat transfer from the outside and increases the pressure in the storage tank 110 .

[0081] Always maintain the pressure in the storage tank 110 at the level of atmospheric pressure, the safety valve 111 opens and the vapor is released outside the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com