Method for treating arsenic-containing industrial wastewater

A technology for industrial waste water and waste water, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve problems such as harsh reaction conditions, achieve low risk, reduce treatment costs, reduce The effect of residue production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

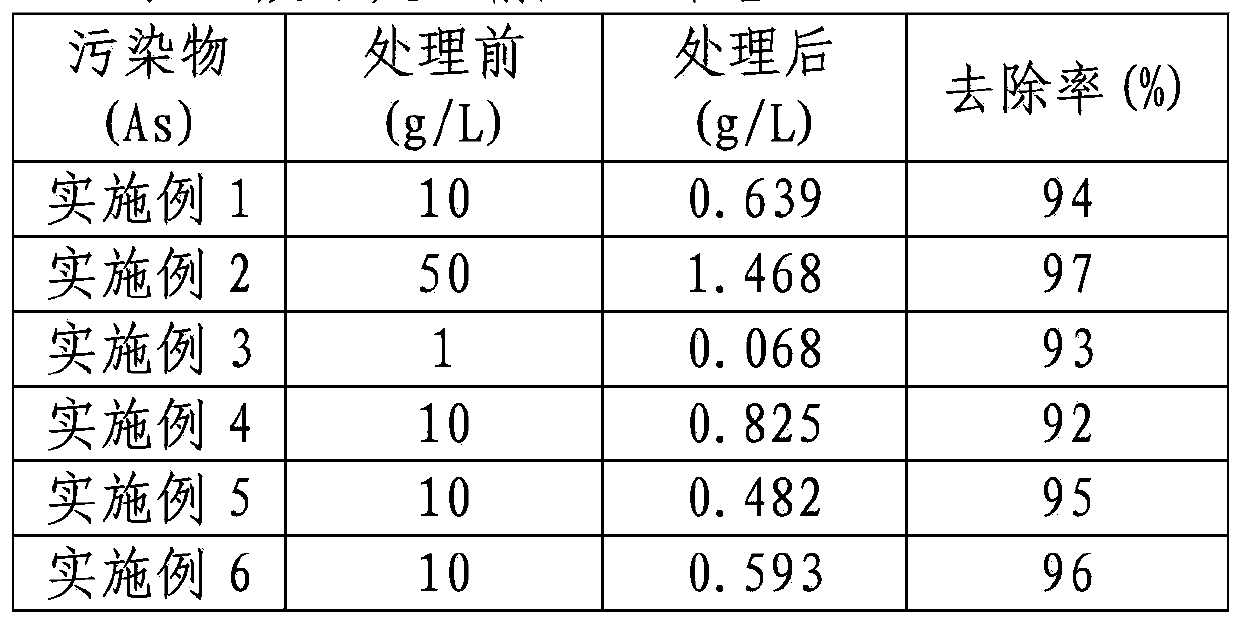

Embodiment 1

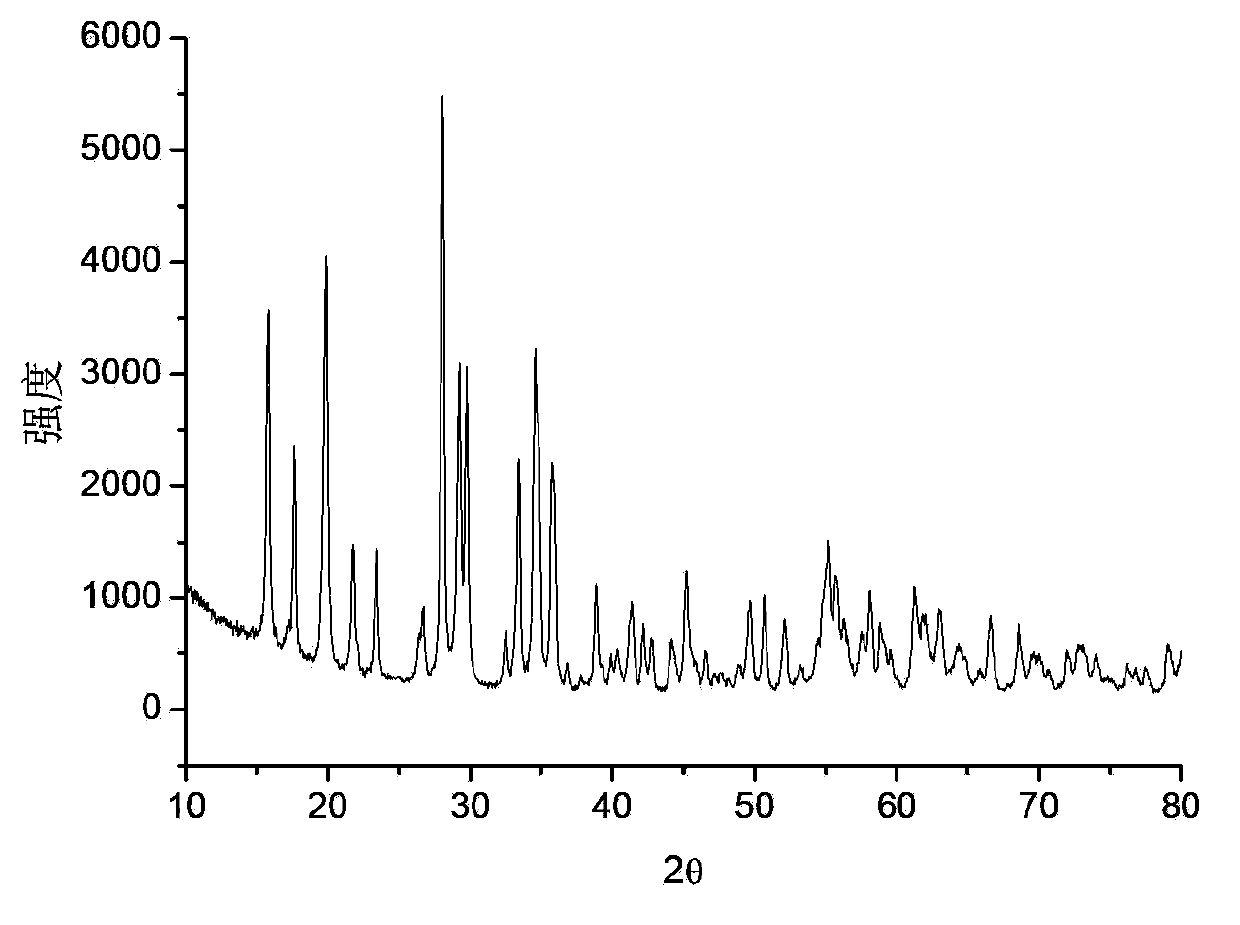

[0022] Na 3 AsO 4 .12H 2 O was dissolved in 100ml of distilled water to make a solution containing As: 10g / L, and concentrated sulfuric acid was added at room temperature to adjust the pH to 1.1; it was heated to 95°C under mechanical stirring (200rpm); 2 (SO 4 ) 3 .xH 2 O and FeSO 4 .7H 2 O was dissolved in 100ml of distilled water at the same time to prepare a mixed iron solution containing Fe(III): 7.5g / L and Fe(II): 3.75g / L. Use a peristaltic pump to add the mixed iron solution into the arsenic solution at a speed of 0.4ml / min, drop it for about 4 hours, and keep it at 95°C for 4 hours after the drop, cool to room temperature after the reaction, and separate the solid and liquid to obtain a stable The precipitation of scorodite crystals, the X-ray diffraction analysis and scanning electron microscope analysis pictures of the precipitation are as follows figure 1 and figure 2 shown.

Embodiment 2

[0024] Na 3 AsO 4 .12H 2 O was dissolved in 100ml of distilled water to make a solution containing As: 50g / L, and concentrated sulfuric acid was added at room temperature to adjust the pH to 0.8; it was heated to 70°C under mechanical stirring (200rpm); 2 (SO 4 ) 3 .xH 2 O and FeSO 4 .7H 2 O was dissolved in 100ml of distilled water at the same time to prepare a mixed iron solution containing Fe(III): 28g / L and Fe(II): 14g / L. Use a peristaltic pump to add the mixed iron solution into the arsenic solution at a rate of 0.3ml / min, drop it for about 6 hours, and keep it at 95°C for 2 hours after the drop, cool to room temperature after the reaction, and separate the solid and liquid to obtain a stable Precipitation of scorodite crystals.

Embodiment 3

[0026] Na 3 AsO 4 .12H 2 O was dissolved in 100ml of distilled water to prepare a solution containing As: 1g / L, and adjusted to pH 2.0 by adding concentrated sulfuric acid at room temperature; heated to 90°C under mechanical stirring (200rpm); 2 (SO 4 ) 3 .xH 2 O and FeSO 4 .7H 2 Dissolve O at the same time in 100ml distilled water to prepare a mixed iron solution containing Fe(III): 0.75g / L and Fe(II): 0.4g / L. Use a peristaltic pump to add the mixed iron solution into the arsenic solution at a rate of 0.8ml / min, drop it in about 2 hours, keep it at 95°C for 6 hours after the drop, cool to room temperature after the reaction, and separate the solid and liquid to obtain a stable Precipitation of scorodite crystals.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com