Apparatus and method processing material by ultrasonic apparatus

An ultrasonic and ultrasonic welding technology, which is applied in chemical instruments and methods, lamination devices, and layered product processing, can solve problems such as energy loss and achieve low shear force and small wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

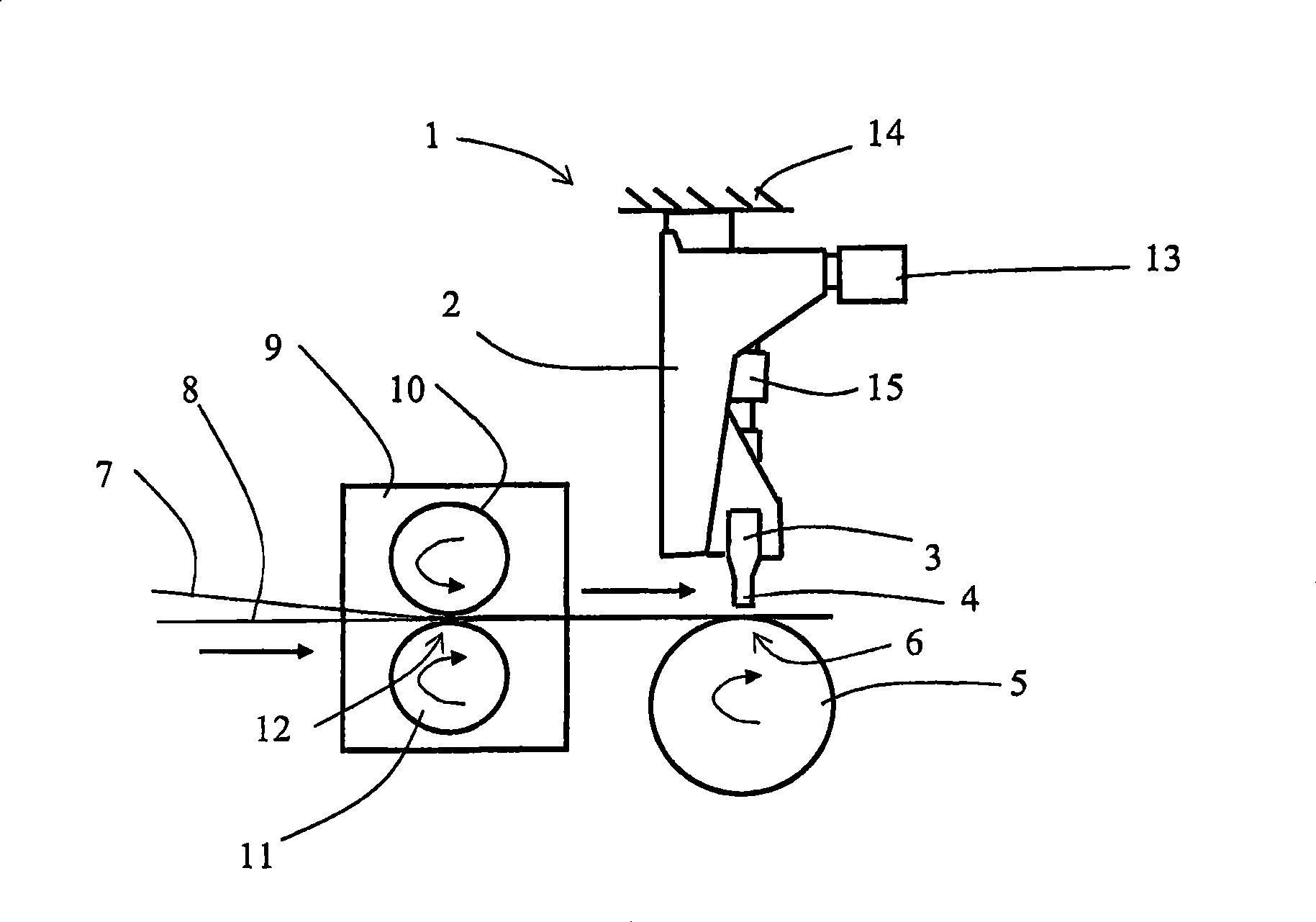

[0022] figure 1 is a schematic side view of an apparatus 1 for sonication, wherein the apparatus is used in connection with the present invention. More specifically, according to the prior art, the device 1 comprises an ultrasonic device 2 with a sonotrode 3 implemented with a contact device 4 , namely an end piece.

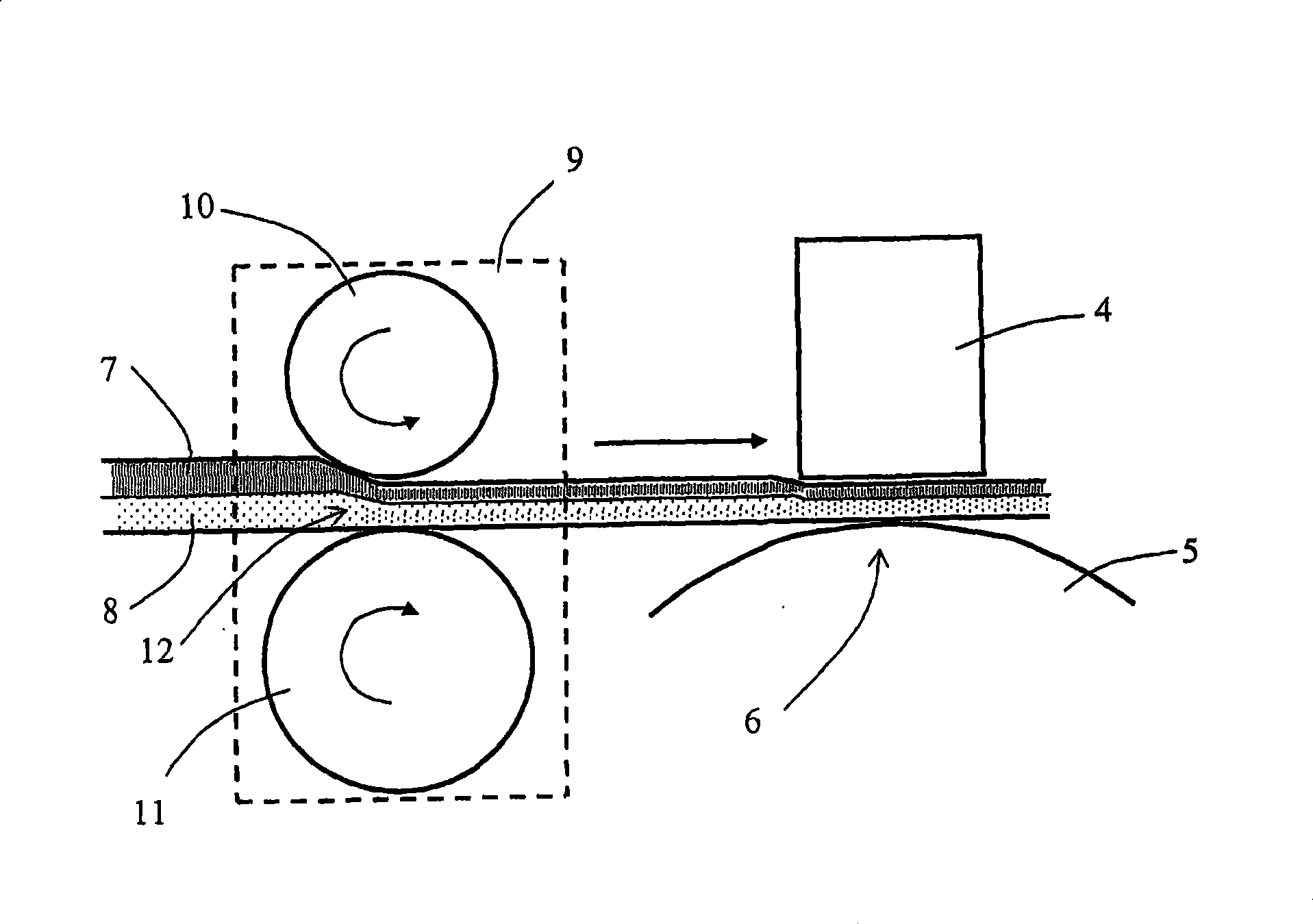

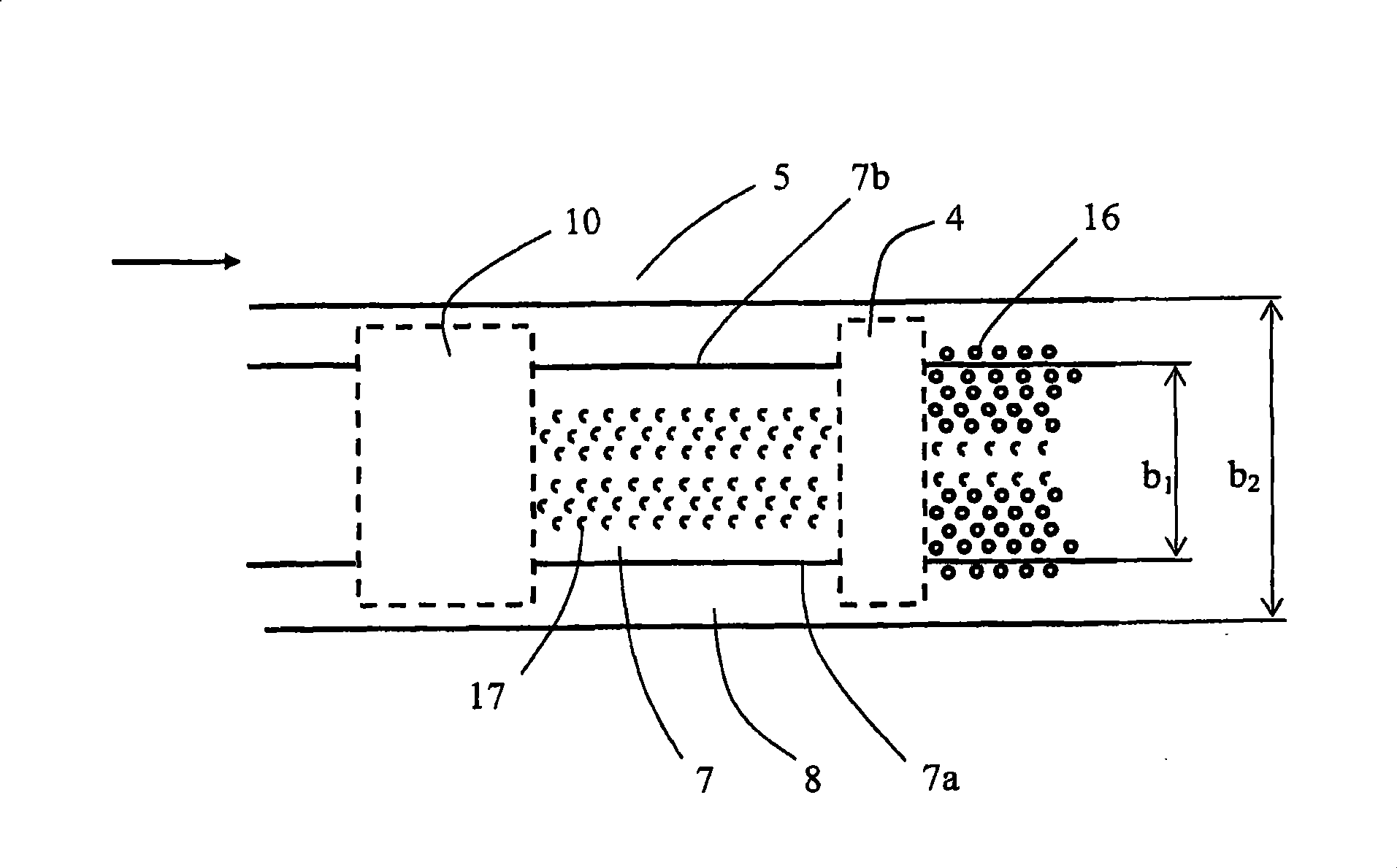

[0023] pass figure 1 It will be appreciated that the ultrasonic device 2 is arranged in close proximity to a rotating abutment roller 5, the periphery of which roller 5 defines an abutment surface. The backup roll 5 is also suitably provided with a pattern for the ultrasonic treatment in question. The contact device 4 of the sonotrode 3 also faces the material and is arranged at a small distance from the outer circumference of the backup roll 5 . A small gap 6 is formed in this way, that is to say a relatively small distance is formed between the contact device 4 and the outer peripheral surface of the support roller 5 . A laminate consisting of two material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com